Nominate now for the 3D Printing Business Awards 2023.

Aerospace and protection contractor Lockheed Martin, steel 3D printer producer Velo3D and aerospace half inspection firm Vibrant have collaborated with the US Division of Protection’s (DoD) LIFT Institute to evaluate the validity of 3D printing hypersonic ramjet engines.

The group manufactured and examined the elements to find out whether or not additive manufacturing strategies can be utilized to effectively and reliably produce licensed mission-ready ramjet engines.

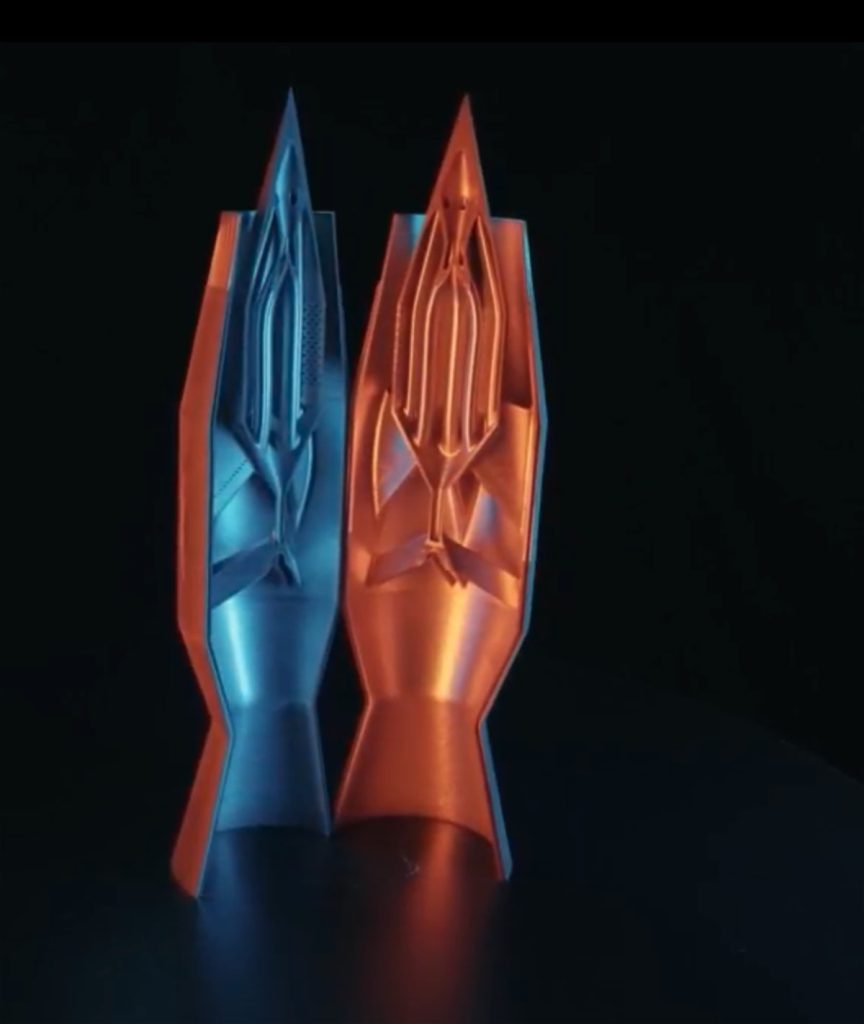

These subtle engines, not like their turbojet counterparts, possess only a few shifting elements and an especially advanced inside construction. Excessive stress is produced by “ramming” exterior air into the combustor utilizing the ahead velocity of the plane. Compression happens by a sequence of shock waves which, along with the inner geometry, compress and decelerate the air till it turns into subsonic within the combustion part.

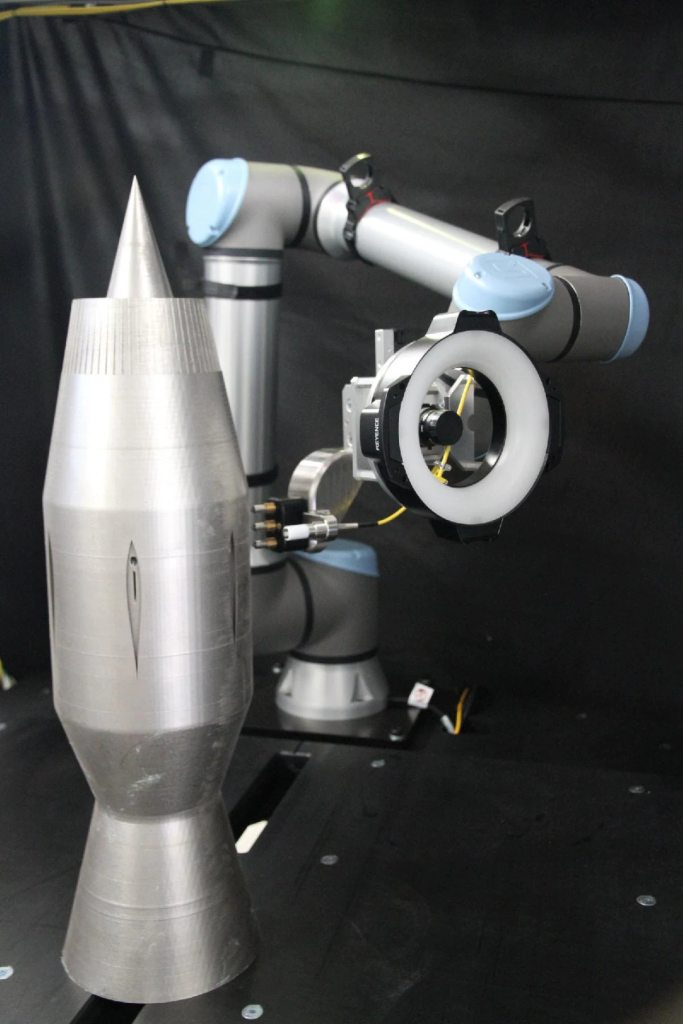

As soon as 3D printed utilizing Velo3D’s laser powder mattress fusion (LPBF) expertise, the ramjet’s have been subjected to Vibrant’s acoustics-based Course of-Compensated Resonance Testing (PCRT). This testing course of analyzed quite a lot of key bodily properties, together with stress state, half integrity, geometry, and floor end.

In the end, this undertaking has been considered as a hit, with the group’s consideration now turning to the subsequent analysis stage. This subsequent stage will think about the fatigue conduct of 3D printed elements, and transfer in the direction of “born-certified” elements.

“When all of it backed out, it was a really profitable program,” commented Dr. John Keogh, LIFT’s Engineering Director. “I used to be totally impressed by the entire physique of labor. The group of Velo, Lockheed Martin and Vibrant shaped a robust group of companions who’re in all probability a few of the closest—if not the closest—to fixing this drawback of qualification and validation or certification of AM elements for mission-critical and safety-critical functions.”

Seeking to the longer term, Keogh added “We need to see hypersonic elements born proper out of the machine which might be already licensed by means of the info stream we’ve captured to again it up.”

A transfer in the direction of 3D printed hypersonic engines

In recent times, the protection and aerospace industries have skilled a rising urge to advance the event of propulsion techniques that may obtain supersonic (above Mach 1, the velocity of sound) and hypersonic (above Mach 5) flight speeds.

3D printing is being more and more acknowledged as a expertise that may manufacture these advanced, single-piece engine designs at lighter weights and in much less time than standard manufacturing.

Again in 2022, US aerospace start-up Hermeus efficiently examined its partially-3D printed hypersonic Chimera engine. Throughout testing, the Chimera proved able to transitioning from turbojet mode right into a high-Mach velocity ramjet mannequin. Elsewhere, Aerojet Rocketdyne has additionally carried out flight testing of its 3D printed scramjet engine, as a part of a US hypersonic missile analysis undertaking.

Now, by the LIFT institute, the DoD is investing assets into assessing whether or not these additively manufactured engines can reliably function beneath the acute environmental circumstances produced throughout hypersonic flight.

One in every of more-than-50 lively tasks beneath contract from the LIFT Institute, the ramjet undertaking can be taking part within the ongoing “Hypersonic Problem.” This initiative is funded by the DoD’s Manufacturing Expertise Program, and is being overseen by the Workplace of the Beneath Secretary of Protection for Analysis and Engineering.

The last word aim of this problem is to determine which supplies and/or manufacturing processes can present the most efficient and environment friendly pathways to automobiles and missiles able to hypersonic flight.

LPBF 3D printed hypersonic ramjet engines

By means of the ramjet undertaking, the group sought to determine what information streams they might gather through the LPBF 3D printing course of, after which carried out a well-established Design of Experiments to interrogate these information streams. Lockheed Martin established the standard assurance verification method used within the undertaking.

The ramjet engine was 3D printed utilizing Velo3D’s Sapphire 1 MZ LPBF 3D printer, along with Inconel 718 steel alloy. The Sapphire 1 MZ can 3D print objects as much as one meter in top, with the ultimate ramjet piece measuring 751 mm tall. Furthermore, the Sapphire system additionally incorporates a whole bunch of sensors that monitor, report and save metrics all through the construct course of. “Velo3D’s machine collects an immense quantity of information,” defined Keogh. “It additionally gives a really beneficiant construct envelope oriented in the direction of quantity manufacturing.”

Because of Velo3D’s Clever Fusion and the Sapphire’s patented recoater expertise, no help materials was wanted when 3D printing the ramjet mannequin. In the course of the 3D printing course of, as soon as every layer of powder is laid down, the blade that normalizes it’s adopted by a vacuum that picks up extra powder and leaves behind an ideal powder layer. This creates a free house between the blade and the half, eradicating the danger of a collision because the half grows, and eliminating the necessity for helps.

While initially designed to be included right into a supersonic jet engine, the group claims that a couple of small tweaks might simply rework their ramjet engine right into a scramjet (supersonic combustion ramjet). Successfully, a scramjet is a ramjet with an adjusted inlet and outlet nozzle that retains increased airflow speeds by the engine. Theoretically, scramjet-powered automobiles can attain hypersonic velocities exceeding Mach 5.

Along with the ramjet engines, the group additionally 3D printed quite a lot of materials check elements. Named for his or her distinctive shapes, the “canine bone” elements have been used for tensile pull testing, and the “detergent pacs” have been produced for density and floor end analysis.

Acoustics-based testing

The 3D printed ramjets and check items have been then assessed utilizing Vibrant’s PCRT course of. Throughout testing, PCRT used ultrasonic frequencies between 5 and 500 kHz to excite the vibrational modes of the half for a couple of seconds or minutes at a time. The pure resonance frequencies of the half, distinctive to each its geometry and materials properties, have been recorded, saved and analyzed.

By means of this course of, the group might determine resonance fingerprints which mirror the stress state, half integrity, geometry, and floor end of the part. In response to Vibrant, the PCRT may doubtlessly be correlated to vitality density and scanning velocity settings, uncooked materials properties and sourcing, construct place, cooling charges, and post-processing strategies like hot-isostatic-pressing and residual stress. Basically, it’s claimed that any course of parameter affecting materials state and mechanical properties could be assessed by PCRT.

As every half’s resonance values are captured at totally different frequencies and in contrast in opposition to the others, the metrics of high-quality elements coalesce across the similar values. As such, outliers stand out and could be simply recognized. Subsequently, confidence-limit boundaries could be decided, while suggestions is supplied that promotes manufacturing consistency and ensures remaining product high quality from batch to batch.

“It is a very enticing method to couple with and complement additive manufacturing as a result of it’s volumetric, fast, and it doesn’t require damaging testing,” commented Keogh. “It may present indications of porosity, floor defects, aberration within the geometry and so forth.”

Subscribe to the 3D Printing Business publication to maintain updated with the newest 3D printing information. You can too comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing business? Go to 3D Printing Jobs to view a number of obtainable roles and kickstart your profession.

Featured picture reveals John Keogh (left), technical lead, and undertaking supervisor Brad Pal holding a minimize part of the 3D printed ramjet. Photograph through LIFT.