3D printing is elevating the usual of take care of most cancers sufferers present process radiotherapy at Swansea’s Singleton Hospital in Wales.

Their new method entails the creation of specialised equipment referred to as boluses, designed to make sure exact radiotherapy doses for cancers positioned close to the floor of the pinnacle or neck.

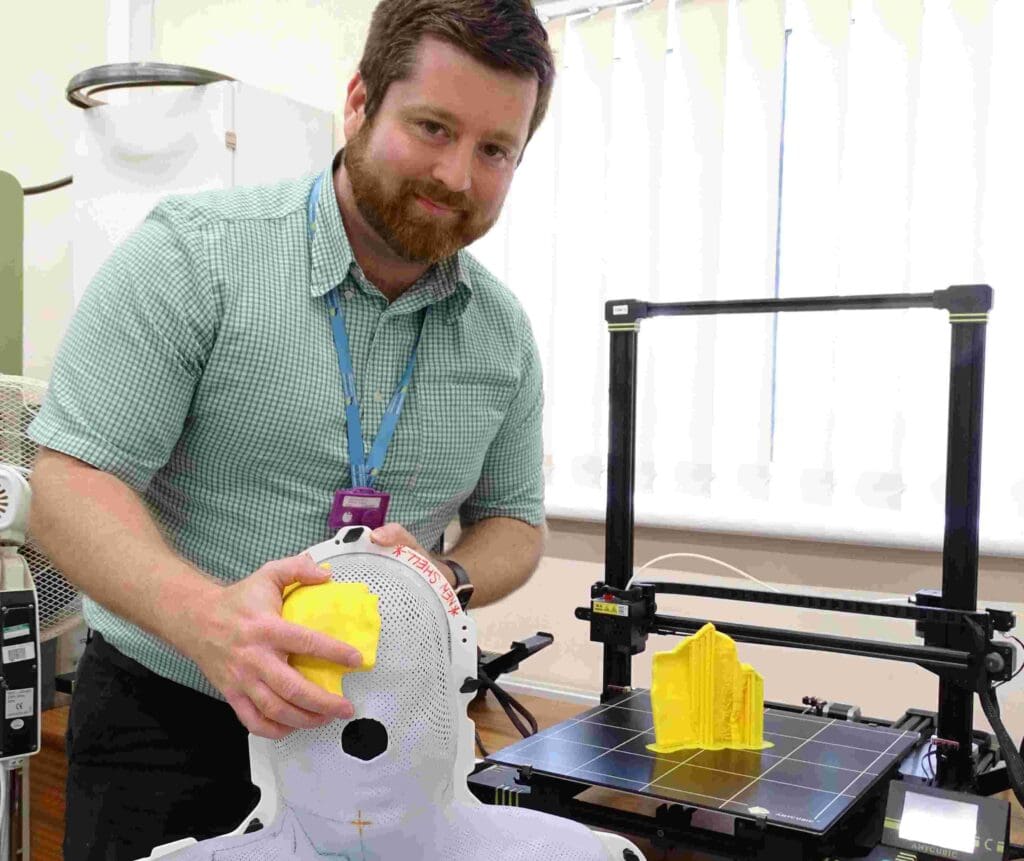

Historically, sufferers receiving head or neck radiotherapy put on a masks, generally known as a shell, crafted from thermoplastic. This masks successfully immobilizes the pinnacle and neck, guaranteeing the accuracy of the therapy. Nonetheless, some circumstances require the addition of a bolus to optimize radiation supply. Beforehand, these boluses have been painstakingly handcrafted from wax, a course of vulnerable to imperfections and air gaps.

The breakthrough got here when Rhys Jenkins, a sophisticated radiotherapy physics technologist, found the potential of 3D printing for bolus manufacturing. These 3D-printed boluses exactly match the therapy plan, making certain correct placement and eliminating air gaps. This innovation not solely enhances therapy accuracy but in addition saves priceless workers time, as boluses can now be produced swiftly with the push of a button.

The bolus, appearing as tissue materials, permits radiation to construct up on the right depth earlier than reaching the affected person’s pores and skin. This degree of precision was difficult to attain with handbook strategies, which frequently led to errors in form and placement.

Because of the introduction of 3D printing, these points at the moment are historical past. The boluses are meticulously designed throughout the therapy strategy planning stage and printed precisely as meant, seamlessly becoming onto the therapy shell.

This development boosts confidence in therapy supply and considerably reduces the danger of errors.

“The 3D printing has enabled extremely correct and high quality assured boluses to be produced from 3D planning scans, minimising uncertainty and bringing the dose to precisely the place we’d like it,” mentioned Russell Banner, a advisor medical oncologist at Singleton.

“The printer even prints in a single day whereas we’re sleeping to make sure there are not any delays within the therapy pathway.”

Sufferers profit from faster and extra snug software, because the 3D-printed bolus doesn’t require molding to the therapy shell. The transfer to 3D-printed boluses has been celebrated as a constructive step for each sufferers and workers, streamlining the therapy course of and bettering the general affected person expertise.

The result’s extremely correct and quality-assured boluses that decrease uncertainties and guarantee exact radiation doses precisely the place they’re wanted most. This new development demonstrates how additive manufacturing can positively affect most cancers therapy, providing hope and confidence to sufferers and healthcare professionals alike.

Supply: wales247.co.uk

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t overlook to enroll in our weekly additive manufacturing publication to get all the most recent tales delivered proper to your inbox.