Indian AM-focused coaching middle Matrix Moon has bought an EXT 1070 Titan Pellet 3D printer from 3D Techniques, a US-based 3D printer producer.

Matrix Moon has opted for a configuration with an non-compulsory milling spindle software head, permitting hybrid additive and subtractive manufacturing. Utilizing the EXT Titan Pellet system, the corporate will effectively ship numerous vary of purposes like molds, tooling, patterns, and end-use elements for aerospace, automotive, HVAC, and client merchandise. Moreover, Matrix Moon plans to provide pattern elements from its demo middle utilizing the EXT 1070 Titan Pellet 3D printer.

Abhinav Garje, CEO of Matrix Moon Non-public Restricted, stated, “At present I’m extraordinarily delighted and stuffed with immense delight to announce that Matrix Moon is the one firm in India to supply 3D Techniques’ EXT Titan Pellet 3D printer. This cutting-edge global-grade expertise is about to alter the face of producing in India. Think about printing elements as tall as six ft and machining it in the identical printer to your end-use manufacturing purposes. It will now be doable with our newest and distinctive providing. With our continued give attention to Talent India and Make-in-India missions, I consider that the EXT Titan Pellet 3D printer has the potential to rework meeting traces and the way merchandise are manufactured in India. Together with 3D Techniques, we not solely endeavor to reinforce the adoption of additive manufacturing in manufacturing but additionally to make India a world manufacturing hub with such pioneering expertise. EXT Titan Pellet is a essential step in that route.”

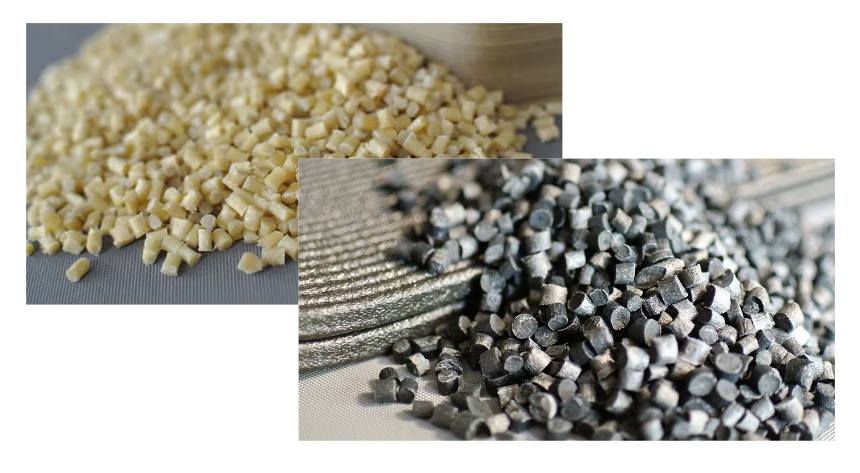

Pellet extrusion expertise: A sooner, cheaper strategy to 3D print

3D Techniques’ EXT Titan Pellet techniques are “acknowledged” for effectively manufacturing merchandise at decrease prices than typical strategies. The proprietary pellet extrusion expertise allows 10x sooner 3D printing and lowered materials bills. The massive-format 3D printers are outfitted with energetic chamber heating, enabling the utilization of high-temperature glass- or carbon-filled engineering supplies like ABS, Nylons, PC, PEI, and PEKK.

The EXT Titan Pellet techniques facilitate massive print volumes, enabling full-scale prototyping and end-use manufacturing in new purposes. 3D Techniques’ extrusion 3D printers create massive format tooling, molds, and patterns for varied foundry makes use of, together with sand casting. Matrix Moon expects its EXT 1070 Titan Pellet system to rework India’s second-largest casting business, following China.

“Matrix Moon has demonstrated its understanding of the Indian manufacturing sector and is dedicated to advancing additive manufacturing in essentially the most populous nation on Earth. By selecting 3D Techniques’ EXT Titan Pellet 3D printer, Matrix Moon is providing an unparalleled platform that may embrace pellet extrusion, filament extrusion, and a subtractive milling software head on the identical machine. Combining these additive and subtractive applied sciences together with pellet supplies will permit Matrix Moon to handle a better breadth of purposes for its clients and develop the variety of EXT Titan Pellet techniques in use in India to rework manufacturing,” added Deelip Menezes, Managing Director, 3D Techniques India.

EXT 1070 Titan Pellet 3D printer technical specs

Construct quantity:

| 1070mm X x 1070mm Y x 1219mm Z (42”x42”x48”) | |

| Reduce | 1070mm X x 990mm Y x 990mm Z (42″ x 39″ x 39″) |

System necessities:

| Energy Enter | 208V Three Part 100A |

| Machine Weight | 2041kg (4500lbs) |

| Machine Footprint | 2.4m x 2.1m x 2.6m (8′ x 7′ x 8.6′) |

Toolhead configurations:

| EXT 1070 Titan Pellet | |

| One Toolhead (Customary) | Pellet Extruder |

| Two Toolheads | Twin Pellet Extruders, Pellet + Filament Extruder, Pellet Extruder + Spindle |

| Three Toolheads | Pellet Extruder + Filament Extruder + Spindle, Twin Pellet Extruders + Spindle |

| EXT 1070 Titan Pellet LT* | *Not suitable with twin pellet or spindle toolhead configurations |

| One Toolhead (Customary) | Pellet Extruder |

| Two Toolheads | Pellet Extruder + Filament Extruder |

| Three Toolheads | Pellet Extruder + Twin Filament Extruders |

Spindle options:

| Pace | 18,000 RPM (1.5HP) |

| Software Dimension | As much as 1/4″ diameter, 4″ size |

| Instruments Changer | 6 software capability |

| Software Calibration | 3-axis sensor configuration |

| Chip Collector | Brush/vacuum chip assortment system |

Extrusion capabilities:

| Pellet Nozzle Diameters | 0.6 mm – 9.0 mm |

| Pellet Layer Heights | 0.4 mm – 6.0 mm |

| Pellet Extruder Throughput | 0.45kg – 13.6kg* (1lb – 30lbs*) per hour |

| Filament Nozzle Diameters | 0.4 mm – 1.2 mm |

| Filament Layer Heights | 0.15 mm – 1.0 mm |

| Filament Throughput | <0.45kg – 0.9kg (<1lb – 2lbs) per hour |

What does the way forward for 3D printing for the following ten years maintain?

What engineering challenges will have to be tackled within the additive manufacturing sector within the coming decade?

To remain updated with the newest 3D printing information, don’t neglect to subscribe to the 3D Printing Trade publication or observe us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you on the lookout for a job within the additive manufacturing business? Go to 3D Printing Jobs for a choice of roles within the business.

Featured picture reveals 3D Techniques’ EXT 1070 Titan Pellet 3D printer. Picture by way of 3D Techniques.