French 3D printing OEM and repair bureau 3DCeram has been chosen to be an official provider of French area propulsion producer ThrustMe.

ThrustMe will now look to leverage 3DCeram’s experience in ceramic additive manufacturing, and exploit the potential of ceramic supplies in aerospace purposes. ThrustMe’s 3D printed ceramic strategy goals to beat the constraints of conventional manufacturing supplies and strategies. The corporate claims that ceramics supply a extra compact, environment friendly, and dependable resolution than conventional manufacturing.

“On 3DCeram’s aspect, we take pleasure in our collaboration with ThrustMe as 3D printed ceramic parts have been efficiently despatched into area, marking a major milestone within the software of additive manufacturing,” commented 3DCeram gross sales consultant Arnaud Roux.

“It signifies a brand new period the place advanced and customised components could be effectively produced, surpassing conventional manufacturing limitations,” continued Roux. “This vital step ahead not solely validates the viability of 3D printing as a manufacturing instrument but in addition evokes us to succeed in additional and unlock the huge potentialities that lie forward.”

ThrustMe adopts additive manufacturing

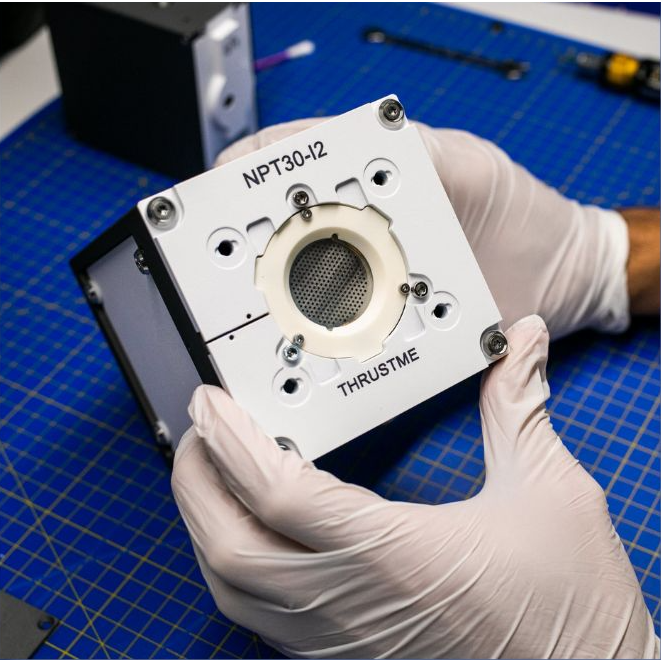

Based in 2017, ThrustMe has already established itself as one of many key actors inside the New Area sector, specializing within the miniaturization of electrical propulsion methods.

The “New Area” period refers back to the latest developments and developments made within the area trade, pushed by non-public firms. In line with Elena Zorzolli Rossi, ThrustMe product supervisor, this elevated commercialization of area is being pushed by speedy technological developments. Zorzolli Rossi claims that firms must take extra dangers, iterate rapidly, and experiment with new concepts to additional developments inside the area trade. “The entire manufacturing chain must be ready to fulfill New Area prices or lead occasions,” added Zorzolli Rossi

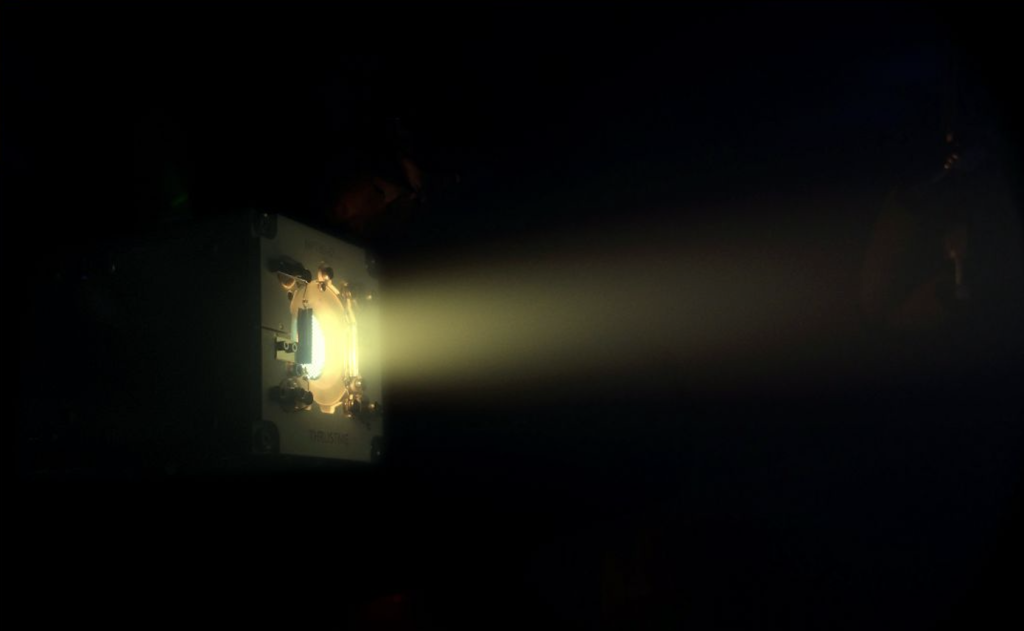

In 2020, ThrustMe made the world’s first profitable demonstration of an iodine-fueled electrical propulsion system in area. ThrustMe now primarily delivers to main satellite tv for pc constellations, and has opened a brand new manufacturing facility able to producing 365 merchandise per 12 months.

In line with Zorzolli Rossi, the corporate selected to undertake 3D printing to fabricate particular components of their thrusters following an intensive analysis course of. Numerous components had been recognized which elevate additive manufacturing above conventional manufacturing strategies.

“Primarily, the area trade typically requires the manufacturing of advanced shapes that can not be simply obtained by way of conventional machining strategies,” defined Zorzolli Rossi. “At ThrustMe, we don’t speak about solely the complexity but in addition the miniaturization, a essential requirement within the growth of our merchandise. In such circumstances, 3D printing presents a transformative resolution by enabling the creation of particular designs with the precision we’d like.”

Moreover, the flexibility of 3D printing was discovered to be a key benefit, permitting the corporate to rapidly iterate and refine designs with out incurring vital prices or lead occasions.

“Conventional manufacturing processes typically contain the creation of molds or tooling, which could be time-consuming and costly,” said Zorzolli Rossi. “With 3D printing, we are able to quickly produce prototypes and iterate on designs with minimal setup time, facilitating a extra agile growth course of and accelerating our time to market.”

Why use ceramics?

In line with Zorzolli Rossi, “a number of components had been completely evaluated earlier than selecting ceramic.”

The choice to make use of ceramic was pushed by “a number of essential components associated to the cruel area surroundings like vacuum and excessive temperature ranges, and particular options of the iodine plasma propulsion system comparable to energetic fluxes of elementary particles, secondary emission, intense sputtering and reactive ion etching.”

Finally, the important thing consideration which influenced this choice associated to the working circumstances the parts would encounter. “A few of our parts are uncovered to excessive temperatures in a chemically energetic plasma surroundings, requiring a cloth with distinctive warmth and chemical resistance,” defined Zorzolli Ross. “Ceramics emerged as the best option on this regard, with its exceptional thermal and chemical stability.”

The broad ranging thermal conductivity of ceramics additionally made it a lovely possibility. Certainly, environment friendly warmth switch and isolation of warmth is claimed to be essential for ThrustMe’s parts. This helps to information thermal fluxes successfully, and prevents overheating or overcooling. Ceramics exhibit a considerable vary of conductivity properties, enabling selective warmth switch and guaranteeing optimum efficiency in these merchandise.

The electrical properties of ceramics additionally performed a major position in ThrustMe’s materials choice course of. “Our parts require a cloth that may successfully isolate and defend towards high-voltage electrical breakdowns,” said Zorzolli Ross. “Ceramics possess distinctive electrical isolation properties, making it a super alternative to fulfill our stringent necessities on this facet.”

Ceramic 3D printing for area

Final 12 months, the French Area Company introduced that it was investigating using ceramic 3D printing in area subsystem optimization. Particularly, the researchers evaluated how 3D printing oxide ceramic supplies may enhance the design of essential subsystems for area propulsion.

The examine highlighted that optimized yttrium aluminum garnet (YAG) xerogel presents fascinating power and creep-resistant properties when 3D printed into advanced shapes. Thus, 3D printed YAG ceramics might be used to type the premise of steel alloys utilized in future turbine blades for deep area exploration.

Moreover, the Worldwide Area Station (ISS) is dwelling to a Made In Area’s ceramic additive manufacturing facility, the Turbine Ceramic Manufacturing Module (CMM). This module incorporates an SLA 3D printer, used to display the feasibility of producing single-piece ceramic turbine parts in microgravity environments. That is stated to have been the primary SLA 3D printer to function on orbit.

Subscribe to the 3D Printing Trade publication to make sure you sustain with the newest 3D printing information. You may also observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing trade? Go to 3D Printing Jobs to view a number of obtainable roles and kickstart your profession.

Featured picture exhibits a ThrustMe aerospace element. Photograph through ThrustMe.