Nominate now for the 3D Printing Business Awards 2023.

Limoges-based ceramics 3D printing OEM and course of supplier 3DCeram Sinto is automating the 3D printing course of for technical ceramics and the manufacturing of inexperienced hydrogen via its 3D printing know-how.

Automation and digitization have gotten more and more key to additive manufacturing, with 3DCeram Sinto striving for higher, quicker, and cheaper manufacturing. Certainly, an increasing number of industries are adopting 3D printing know-how, with additive manufacturing being more and more considered as a high-potential industrial instrument. “Initially thought-about as a prototyping instrument, 3D printing is now being considered as a manufacturing instrument,” commented Richard Gaignon, CEO of 3DCeram Sinto.

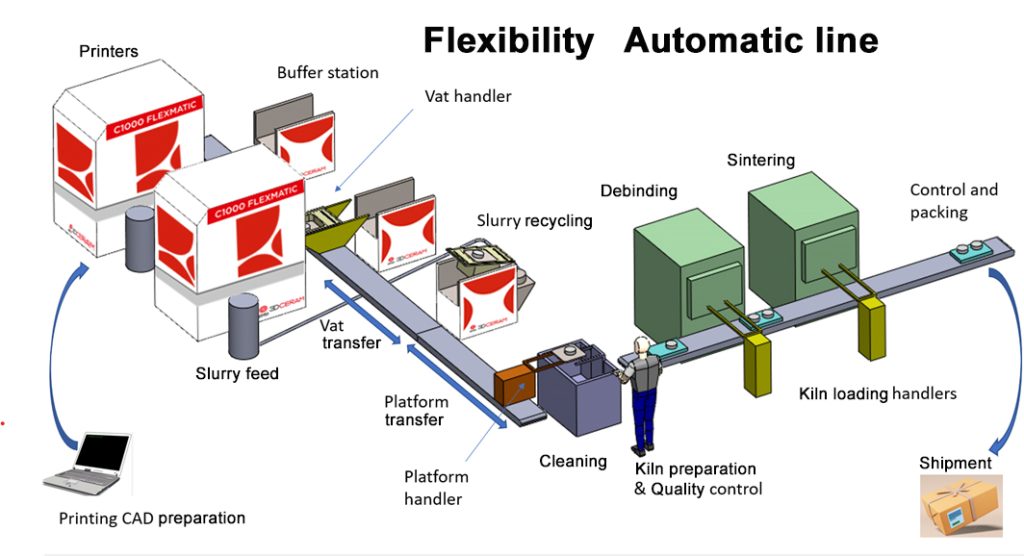

To realize this high-level of automation, 3DCeram Sinto presents a spread of 3D printers together with the C3600 ULTIMATE large-format 3D printer, and the brand new C1000 FLEXMATIC semi-automated 3D printer. This know-how may be integrated into automated manufacturing strains, very best for industrial manufacturing functions.

“Because of the mix of ceramic additive manufacturing and Sinto Group’s experience in automation, we will now think about implementing absolutely automated manufacturing strains,” added Richard Gaignon. “Robots and automatic manufacturing methods can deal with all phases, from design to firing of the components, with minimal direct human intervention.”

3D printing as a manufacturing instrument

3DCeram has outlined quite a lot of stipulations for efficiently industrializing the additive manufacturing course of.

One prerequisite is effectivity and productiveness, with manufacturing processes needing to considerably improve effectivity and productiveness in comparison with current manufacturing strategies to grow to be industrial.

In relation to additive manufacturing, the power to create merchandise with improved geometries that had been beforehand unattainable utilizing various strategies can also be highlighted as being important for industrial manufacturing. This is applicable to merchandise or elements that must be manufactured as a single piece to keep away from meeting challenges, equivalent to foundry cores.

Furthermore, when it comes to industrialization, stereolithography is alleged to be a big asset due to its top-down building course of. Right here, layers are 3D printed from the underside to the highest, foregoing using many helps. As soon as 3D printed, the components may be cleaned, and the less helps there are, the simpler and faster the manufacturing course of turns into. Moreover, dangers of waste attributable to potential breakage throughout help removing are additionally decreased via this course of.

3DCeram calls this a serious benefit, unleashing the capability to design extremely custom-made components that meet particular industrial wants. Furthermore, it’s highlighted that a number of 3D printers may be added to a manufacturing line, whereas nonetheless being manageable by a single operator. This additional will increase productiveness.

The corporate additionally identifies high quality and reliability as key to industrialization, with mass-producing industries looking for repeatability and a constant degree of high quality throughout all 3D printed components. These components should additionally adjust to business requirements and meet person necessities. 3DCeram asserts that important progress has been made on this space, permitting for the massive sequence manufacturing of components that meet the standards of many industries.

Adaptability can also be famous as an vital high quality, with the manufacturing know-how needing to be adaptable to completely different manufacturing volumes based on demand. Additive manufacturing excels on this space, based on 3DCeram, because it presents “mass customization.” This permits the manufacturing of various product sequence in a single run, offered that the printing mattress’s capability permits it.

Ease of integration can also be highlighted as being key to enabling industrialization, with the additive manufacturing course of needing to function in an automated meeting line to be industrial.

To allow this automation, and tackle issues referring to design limitations, 3DCeram developed its “Construct It” plugin. This software program plugin is an elective addition to the CPS machine software program, and presents quite a few options to arrange 3D printing tanks, optimize the association of components for 3D printing, and test and restore 3D printing information.

What’s extra, a brand new model of the CPS machine software program known as CPS 2.0 was not too long ago launched to permit for larger industrialization of additive manufacturing. For example, this new software program features a “C-Print” mode, permitting a single operator to launch a manufacturing course of in just some easy clicks.

Coaching can also be outlined as being essential to adopting 3D printing for industrial functions. “At our scale, we have now carried out a complete coaching program for our machines and processes, which is included within the preliminary package deal. As is customary with machine instruments, steerage is critical, and we take pleasure in being greater than only a provider – we try to be a real accomplice to our industrial purchasers. That’s why we place nice significance on the standard of our coaching applications,” defined 3DCeram Gross sales Director Maxence Bourjol. “When it comes to coaching content material, we provide intensive help that enables us to share our experience and produce our companions to a degree of proficiency that grants them full autonomy upon completion of the coaching.”

Automated manufacturing strains: a revolutionary method

By way of its mixture of ceramics 3D printing and an experience in automation, 3DCeram Sinto now presents absolutely automated additive manufacturing manufacturing strains from design to post-processing. This considerably will increase effectivity and reduces manufacturing prices, paving the way in which for brand new functions in numerous industrial sectors.

“We have now a serious asset, our stereolithography know-how! It permits for the automation of 3D printing of technical ceramics attributable to its distinctive traits (few to no helps, giant printing platforms, and so on.) that improve effectivity, precision, and course of reproducibility,” defined Bourjol.

Certainly, the massive construct volumes of stereolithography 3D printers makes them particularly properly suited to mass manufacturing functions. 4 years in the past, 3DCeram launched the C3600 ULTIMATE, the corporate’s largest 3D printer with a construct quantity of 600 x 600 mm. Outfitted with 4 lasers, the C3600 can produce giant portions of components at substantial 3D printing speeds which meet industrial wants.

3DCeram’s newest 3D printer, the C1000 FLEXMATIC, can also be properly suited to industrial manufacturing, with a semi-automated manufacturing model of the C1000 FLEXMATIC additionally obtainable. This 3D printer may be geared up with 2 lasers to optimize 3D printing pace, making it very best for industrial clients with mass 3D printing objectives. A fabric recycling station may also be added to the C1000 FLEXMATIC, decreasing materials waste and boosting automation.

This stereolithography providing additionally permits for wonderful precision and positive particulars on optimized geometries, making it appropriate for functions the place dimensional accuracy is required.

Learn how to efficiently implement an automated 3D printing line

When creating an industrial 3D printing manufacturing line for technical ceramics, shut collaboration between the provider and the client is significant.

“Though a number of machines may be built-in into an automated line, every implementation is exclusive, because it relies on the precise manufacturing undertaking of the client, the merchandise that might be devoted to the road, and the set up location,” commented Gaignon.

By carefully collaborating, the provider and the client can anticipate potential challenges, optimize the road configuration, establish key functionalities, and maximize operational effectivity. This ensures a easy and profitable implementation of the economic 3D printing manufacturing line.

“Our machines are geared up with superior sensors that monitor manufacturing parameters in real-time, permitting changes to the method situations and guaranteeing the standard of the components on the finish of printing,” defined Bourjol. “We’re already in a position to provide automated strains to our clients at the moment.”

Optimizing Excessive-Strain Hydrogen manufacturing with AM

3DCeram’s 3D printing know-how can also be being employed as a part of the European HyP3D Mission. Leveraging cutting-edge 3D printing manufacturing strategies, the undertaking goals to showcase the viability of a disruptive high-pressure Stable Oxide Electrolysis Cell (SOEC) know-how.

The HyP3D undertaking seeks to ship an ultra-compact, high-pressure standalone SOEC stack able to changing electrical energy into compressed hydrogen. This undertaking goals to harness 3D printed SOEC cells with a considerable energetic space of 70 cm2, embedded functionalities, and the capability to realize hydrogen manufacturing at excessive present densities exceeding 0.90A/cm2 (~1.3V) underneath situations of 850°C and 5+ bar strain.

3DCeram’s position on this undertaking pertains to an intricate optimization course of spanning 3D printable feedstock Zr8Y, 3D printing parameters, and thermal therapies. By formulating specialised slurries for SLA 3D printing using business YSZ powders, the groups are finding out rheological habits and conducting 3D printing exams. The innovation extends to designing optimum procedures, culminating within the manufacturing of complex-shaped components mirroring the ultimate cell dimensions.

3DCeram will make the most of the C1000 Flexmatic as a part of a semi-automatic manufacturing line. With a 320 x 320 mm construct quantity, the C1000 Flexmatic is alleged to be important for the profitable completion of the undertaking.

HyP3D is alleged to signify a paradigm shift from conventional ceramics SOEC processing. This new course of will create ultra-high energy density SOEC stacks, boasting an influence output of two.14 kW inside a compact quantity of 630 cm3. As such, this can create a threefold improve in particular energy per unit quantity (3.4 kW/L) and a fourfold rise in particular energy per unit mass (1.10 kW/kg).

Moreover, 3DCeram is collaborating with IREC to formulate optimum 3D printing methods, guaranteeing reliability and maximizing manufacturing yield. This undertaking aligns with the broader aims of advancing the hydrogen financial system, decreasing time-to-market considerably, slashing uncooked materials consumption by 76%, and minimizing the preliminary funding by 42% in comparison with standard manufacturing processes.

Subscribe to the 3D Printing Business e-newsletter to maintain updated with the newest 3D printing information. It’s also possible to comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing business? Go to 3D Printing Jobs to view a collection of obtainable roles and kickstart your profession.

Featured picture reveals the C1000 FLEXMATIC’s two lasers. Photograph by way of 3DCeram.