Wow it has been a busy couple of months on the building web site! A lot has been occurring however we’ve been operating arduous simply to maintain up with venture administration and spring duties on the farm. Lastly we’re getting a couple of wet days and so are comfortable to replace our building web page right here on the weblog. We’re very pleased with and grateful for all the contractors who’ve introduced their experience and hustle to drag the venture collectively. It’s such a pleasure to work with all of those high-quality people:

- Staff Ag Engineering – web site engineering, permits and venture certification

- Barton Associates – electrical engineering and permits

- Weaver Hauling and Excavating – digging holes, grading, constructing roads, hauling rock, putting in pipes

- Franklin Builders – Barn and pavilion constructions, fixtures and concrete work

- Kurtzcrete – concrete tanks within the waste reception facility

- DML Poured Partitions – spherical tanks for manure and digester

- Nutrient Management Techniques – manure pumps, mixers, and digester equipment.

Listed here are some footage of the venture in chronological order. Please watch this web site for extra progress within the coming months!

Kinds are set and reinforcing bar put in for the waste reception tanks.

This group of enthusiastic students from the Large Spring Future Farmers of America go toed the venture web site on the day of our first concrete pour.

These 10,500 gal capability concrete tanks are the core of the waste reception, processing and mixing space.

As soon as the tanks have been performed, the professional barn building group from Franklin Builders put collectively this 285’ x 49’ construction in about two weeks. They have been flying! The finished barn will home each the dairy cattle and the waste reception and processing space.

The waste reception space is contiguous with the dairy barn (separated by a concrete wall) to make environment friendly use of supplies and area.

PVC piping put in by Weaver Hauling and Excavating. These pipes from tanks to the digester and digestate storage tank have been strain examined and inspected earlier than set up of the concrete ground slab.

Ground slab set up earlier than divider partitions and management/mechanical room. White vertical pipe at proper is one in every of two statement wells for leak detection.

Slab, divider partitions, and management/mechanical room put in. Steel construction at proper is “push off guard” for loading of bulk meals waste into pits by way of tractor loader. The momentary wood stand between room and push off guard is the longer term web site of the industrial meals waste grinder.

Waste reception space from outdoors with security fence and a few manure pumps put in by Nutrient Management Techniques.

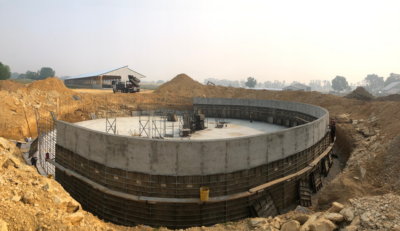

In the meantime, close by the professional machine operators from Weaver Hauling and Excavating dug one other big gap that may develop into the ultimate liquid storage tank for supplies after digestion. It may not look that thrilling from the footage however we actually appreciated the expert craftsman ship wanted to dig a 96’ diameter spherical gap, 12 toes deep. Simply realizing the place to place all of the soil a problem in itself! Additionally they hit a considerable quantity of limestone.

This pit was engineered to be a selected top in relation to the barn and waste assortment space. The base was then lined with clay to make sure a secure floor for the tank backside.

A stone base and footer drain pipe are laid in place earlier than the reinforcing rods are put in.

The crew from DML Poured Partitions has rebar put in on the tank ground and concrete truck is able to pump. We might see this pumper crane from throughout the farm!

It was a protracted sizzling day of pouring and leveling concrete within the fishbowl for the blokes from DML.

As soon as the ground had set, the DML crew constructed these partitions with types and rebar in response to the engineer’s plans.

The finished tank needed to remedy for 2 weeks earlier than backfilling the partitions.

The farm crew had somewhat enjoyable with graffiti earlier than the massive tank was backfilled!

This pavilion would be the future gathering web site for public excursions and academic visits. Franklin Builders put it up in two days!

That’s the place we stand as of the top of June. Preserve a watch out for extra updates as we proceed to construct the digester tank and begin putting in mechanical gear.

Thanks for studying!!!