Scientists from Nanyang Technological College Singapore (NTU Singapore), the Singapore Centre for 3D Printing (SC3DP), and Japanese electronics agency Panasonic have developed a brand new multi-material 3D printer.

Digital parts and units are historically manufactured from inflexible metals, silicone, and ceramics. Nevertheless, there’s rising demand for versatile and wearable electronics that may be bent, twisted, and conformed to varied surfaces.

This new 3D printer goals to fulfill these market calls for. Incorporating multi-wavelength high-power lasers, the 3D printer is designed for fast and simple 3D printing of good, versatile, and wearable digital units.

“Our challenge goals to discover a method to 3D print new supplies like natural polymers and carbon-based supplies like graphene, which has properties that permit them to be printed or coated onto versatile substrates like plastics or materials, creating versatile and stretchable circuits,” explains challenge co-lead Affiliate Professor Murukeshan Vadakke, from NTU Faculty of Mechanical and Aerospace Engineering (MAE) and SC3DP.

“3D printed versatile electronics pave the way in which for extra snug and cellular wearable units as they are often lighter and smaller. We are able to now create distinctive constructions that have been beforehand not possible with conventional inflexible electronics.”

This challenge between NTU and Panasonic dates again to 2016. Since then, the group has filed two patents, offered at 11 nationwide conferences, and revealed 11 papers.

The NTU-Panasonic group claims that their new 3D printer may revolutionize additive manufacturing, opening new potentialities for product design innovation with unmatched performance and suppleness.

Panasonic’s new multi-material 3D printer

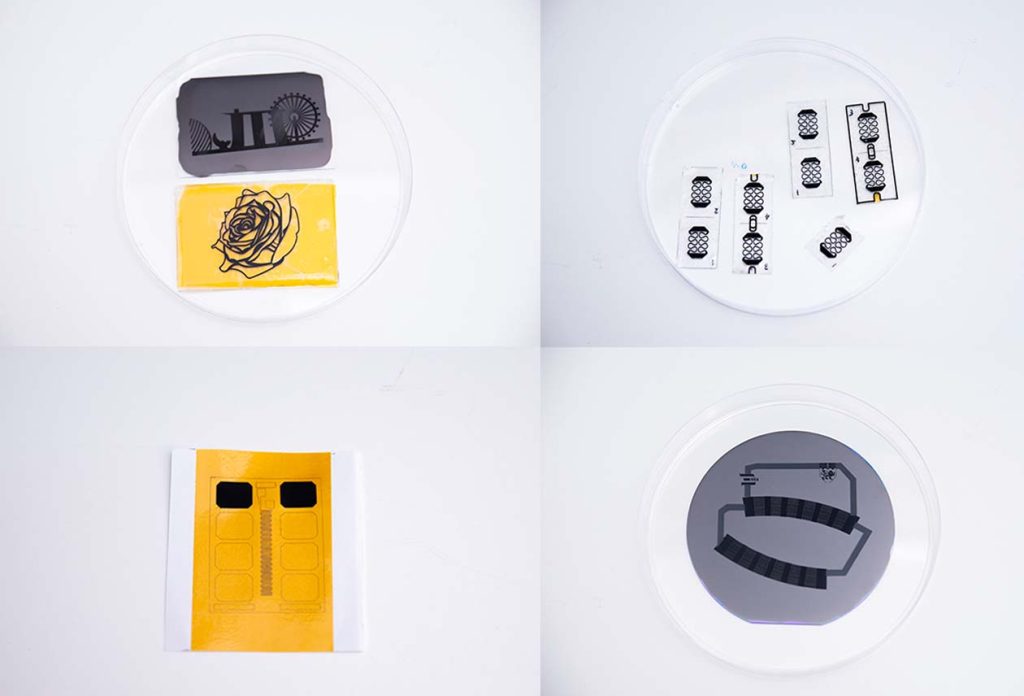

The brand new multi-material 3D printer employs various laser wavelengths. These set off thermal and chemical reactions that may remodel widespread carbon-based supplies, like polyimide and graphene oxide, into a brand new sort of extremely porous graphene. Buildings 3D printed with this novel graphene are mild and conductive. They can be 3D printed or coated onto versatile substrates like plastics, glass, gold and materials, creating versatile and wearable units.

“Our expertise permits the creation of extremely porous and conductive graphene-based materials to be used in numerous purposes,” claims Dr Low Mun Ji, Co-leader of the challenge and Basic Supervisor of Panasonic. “In comparison with conventional graphene manufacturing strategies, our technique is quicker, cheaper, and extremely suitable with a variety of supplies.”

Seeking to the long run, Panasonic has arrange a brand new facility for laser-based manufacturing methods at its Singapore primarily based analysis hub. This new facility will allow additional trials of ideas utilizing parts 3D printed by the multi-material 3D printer. This kinds a part of Panasonic’s “Autonomous Manufacturing unit” idea, for the event of “good factories for the long run.”

Purposes and use-cases

This new 3D printer has already attracted curiosity, together with from the Penang division of American producer JABIL. Jabil Penang is working to combine 3D printed graphene-based electronics into a wise infusion system.

The corporate has already produced a proof of idea with a low-cost intravenous (IV) bag prototype, embedded with a synthetic intelligence (AI) powered 3D printed sensor. This system screens the standing of the IV drip, routinely regulating parameters resembling temperature and stress move. The related data is then transmitted to a smartphone in real-time. This permits medical personnel to remotely and effectively monitor, detect, and management IV capabilities.

The analysis group has additionally obtained funding assist from the Nationwide Affiliation of Mutual Insurance coverage Firms (NAMIC). This funding has been used to check the mixing of 3D printed parts into high-performing electronics like stress sensors and heaters.

Multi-material 3D printing

Final yr, Finland-based bioprinting agency Brinter launched what they declare to be the world’s first multi-material, multi-fluidic bioprinting printhead. Designed to be used with Brinter’s 3D bioprinters, this printhead goals to allow high-precision tissue engineering and regenerative medication purposes. The printhead’s {hardware} will be modified with totally different temperature management and imaging choices. This makes it suitable with all kinds of fabric sorts.

Elsewhere, in 2021, Desktop Steel acquired Belgian recoater system developer Aerosint, to increase their multi-material 3D printing capabilities. Via its patented Selective Powder Deposition expertise, Aerosint can 3D print a number of supplies concurrently. It’s stated that this improves powder effectivity, maximizing value and half throughput beneficial properties.

Subscribe to the 3D Printing Business e-newsletter to make sure you sustain with the most recent 3D printing information. You can too observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing trade? Go to 3D Printing Jobs to view a collection of obtainable roles and kickstart your profession.

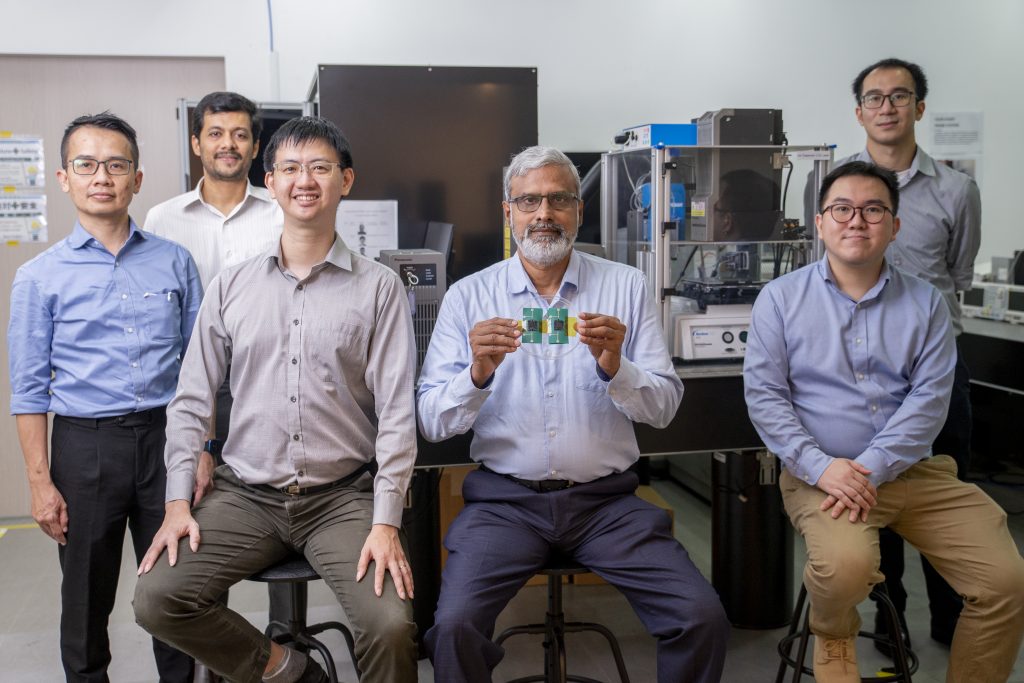

Featured picture reveals the members of the Panasonic-NTU multi-material 3D printer group. Photograph through NTU Singapore.