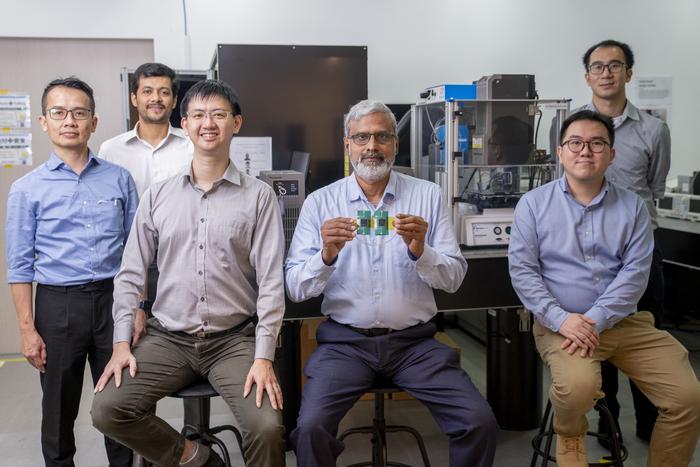

Researchers from Nanyang Technological College, Singapore (NTU Singapore), Panasonic Manufacturing unit Options Asia Pacific, and the Singapore Centre for 3D Printing (SC3DP) have collaborated to develop a multi-material printer able to 3D printing versatile good gadgets shortly. The printer makes use of multi-wavelength high-power lasers to create thermal and chemical reactions, reworking carbon-based supplies right into a extremely porous graphene construction. This graphene materials is light-weight, conductive, and might be printed or coated onto versatile substrates like plastics, glass, gold, and materials. The power to create versatile electronics opens up potentialities for wearable gadgets which might be snug, light-weight, and conformable to varied surfaces.

The newly developed 3D printer has already garnered curiosity from firms like JABIL-MTI Penang, which plans to combine 3D printed graphene-based electronics into a sensible infusion system. A proof-of-concept prototype of a low-cost intravenous fluid bag with an embedded printed sensor powered by synthetic intelligence has been demonstrated. This gadget permits real-time monitoring, management, and detection of abnormalities within the IV drip remotely, offering environment friendly medical care.

The analysis staff additionally explored integrating 3D printed parts into high-performing electronics like strain sensors and heaters. The challenge, supported by the Singapore Financial Improvement Board, has filed two patents, introduced at worldwide conferences, and printed papers. The collaboration between NTU and Panasonic goals to revolutionize 3D printing and spur innovation in product design.

Panasonic has established a brand new facility for laser-based manufacturing programs at its analysis hub in Singapore to conduct additional trials utilizing parts fabricated by the multi-material printer. The power might be led by the researchers concerned within the joint challenge, enabling the exploration of ideas aligned with the “Autonomous Manufacturing unit” idea for good factories of the longer term. The profitable collaboration exemplifies the technical capabilities of SC3DP and its help for business developments and worth creation.

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t neglect to join our weekly additive manufacturing publication to get all the newest tales delivered proper to your inbox.