A bullet piercing the protecting armor of a primary responder, a jellyfish stinging a swimmer, micrometeorites putting a satellite tv for pc: Excessive-speed projectiles that puncture supplies present up in lots of kinds. Researchers continuously intention to establish new supplies that may higher resist these high-speed puncture occasions, however it has been arduous to attach the microscopic particulars of a promising new materials to its precise conduct in real-world conditions.

To deal with this problem, researchers on the Nationwide Institute of Requirements and Know-how (NIST) have designed a technique that makes use of a high-intensity laser to blast microscale projectiles right into a small pattern at velocities that method the velocity of sound. The system analyzes the vitality trade between the particle and the pattern of curiosity on the micro stage then makes use of scaling strategies to foretell the puncture resistance of the fabric in opposition to bigger energetic projectiles, akin to bullets encountered in real-world conditions. This new technique, described within the journal ACS Utilized Supplies & Interfaces, reduces the necessity to carry out a prolonged sequence of lab experiments with bigger projectiles and larger samples.

“If you’re investigating a new materials for its protecting purposes, you do not wish to waste time, cash and vitality in scaling up your exams if the fabric would not pan out. With our new technique we will see earlier if it is value trying into a fabric for its protecting properties,” mentioned NIST chemist Katherine Evans.

Throughout lab experiments, synthesizing small quantities of a brand new polymer—e.g., a couple of milligrams from glassware the dimensions of a espresso cup—may be pretty routine. The problem comes with scaling as much as produce kilograms of fabric to have the ability to take a look at its puncture resistance. For supplies produced from new artificial polymers, scaling as much as enough portions is commonly not doable or sensible.

“The issue with ballistic exams is that you will need to take two steps when making new supplies. You might want to synthesize a brand new polymer that you just suppose might be higher, after which scale it as much as kilogram measurement. That may be a massive leap. The most important accomplishment of this work is that we surprisingly present that the micro-ballistic exams may be scaled and linked to real-world large-scale exams,” mentioned NIST supplies analysis engineer Christopher Soles.

Through the course of the research, researchers used their technique to judge a number of supplies, together with a broadly used compound for bulletproof glass, a novel nanocomposite, and the sturdy, all-carbon materials often known as graphene.

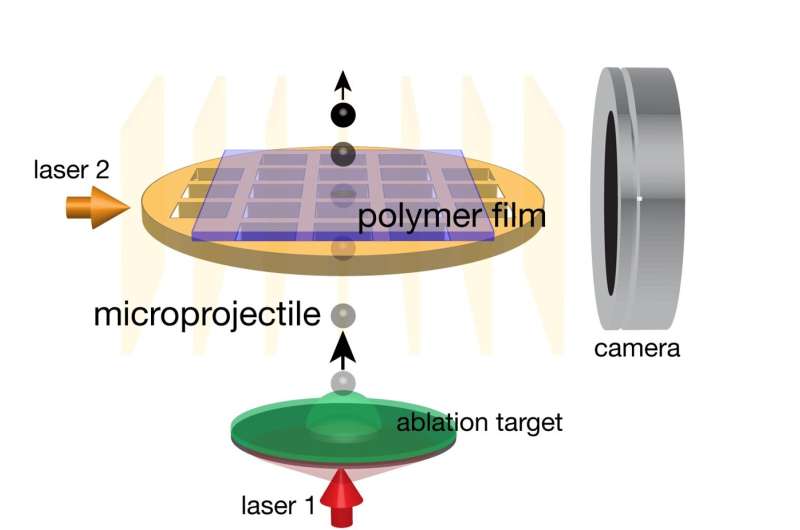

The take a look at is named LIPIT, which stands for laser-induced projectile influence testing. It makes use of lasers to launch a microprojectile made from both silica or glass into a skinny movie of the fabric of curiosity. By means of a course of referred to as laser ablation, the laser creates a high-pressure wave that propels the microprojectile materials towards the pattern.

The researchers first used the strategy to investigate a nanocomposite materials often known as polymer-grafted nanoparticle polymethacrylate (npPMA) composite. It consists of silica nanoparticles that may very well be helpful in a variety of purposes together with physique armor. The laser propels microprojectiles at velocities from 100 to 400 meters per second on the goal materials and measures their influence utilizing a video digicam.

Researchers linked the outcomes of the microprojectile take a look at to what would occur in larger-scale impacts by combining the measurements they obtained on the npPMA with extra mathematical evaluation whereas incorporating current knowledge on the fabric from the analysis literature. Since npPMA is a novel materials and never straightforward to make, they expanded their evaluation to additionally embody a extra generally accessible compound often known as polycarbonate, which is broadly used as a bullet-resistant glass.

The mixed method of utilizing literature outcomes, dimensional evaluation and LIPIT allowed researchers to indicate that the puncture resistance of a fabric is tied to the utmost stress a fabric can take earlier than it breaks, referred to as failure stress. This challenges the present understanding of ballistic efficiency, which is often regarded as associated to how strain waves journey by way of the fabric.

Their new method can establish the power limits of a fabric, or how a lot stress and strain it might probably deal with, with out having to immediately measure these properties beforehand, which might help optimize which supplies to decide on in experiments. This then enabled them to discover supplies akin to graphene, which confirmed that a number of movie layers of the fabric can be utilized in influence resistance purposes equally to high-performance polymers.

“This new paradigm provides us a brand new experimental instrument to judge the hype of a few of these graphene and different 2D supplies which are predicted to have wonderful ballistic properties. Now we have the potential to experimentally confirm if these supplies would outperform traditional ballistic resistant supplies like polycarbonates, even with out scaling up the synthesis of novel 2D supplies, which might be prohibitively expensive,” mentioned Soles.

Their technique might assist establish new supplies for a lot of purposes akin to additive manufacturing, spacecraft safety, higher protecting gear in opposition to animal bites, and even drug supply. Researchers are trying into creating needle-free injections wherein a high-speed stream of fluid often known as a liquid jet punctures the pores and skin. Whereas many purposes intention to keep away from punctures, LIPIT can present insights on this case on the way to most successfully penetrate the pores and skin utilizing liquid jets as projectiles.

As for subsequent steps, the researchers are pursuing a number of avenues. They plan to judge the ballistic resistance of extra novel supplies and have a look at the differing types and configurations. They may even fluctuate the dimensions of the microprojectiles and broaden their velocity vary.

NIST researchers are additionally trying to join LIPIT’s experimental outcomes to 2 sorts of simulations. One is finite aspect evaluation (FEA), wherein the thing of curiosity is modeled as a bunch of easier items which are interconnected. FEA is historically used to simulate the mechanical deformation of the whole pattern. Typically researchers can carry out an FEA simulation quicker than a lab experiment. Nonetheless, in the long run the simulation has to agree with experimental knowledge on the precise materials, mentioned NIST supplies science engineer Edwin Chan.

The second simulation method is named molecular dynamics (MD). It is a form of simulation that’s a lot smaller in scale, trying on the conduct on the molecular stage of supplies akin to polymers. MD can discover how polymer elements akin to molecular chains deform after a projectile strikes the fabric.

“Since we do not have the flexibility to immediately see what the polymer chains are doing, MD is insightful because it provides us a greater concept on why sure polymers are higher for influence resistance,” mentioned Chan.

The researchers count on their methodology to open up many new potentialities for investigating the conduct of supplies.

“With this method, we will ask, “What different issues within the system can we modify, or how can we enhance a fabric for particular purposes?” As a substitute of adjusting the composition of a fabric, you could possibly change its geometry. Or you possibly can research a fabric from nature and see the way it behaves,” mentioned Evans.

Extra data:

Katherine M. Evans et al, The Projectile Perforation Resistance of Supplies: Scaling the Influence Resistance of Skinny Movies to Macroscale Supplies, ACS Utilized Supplies & Interfaces (2023). DOI: 10.1021/acsami.3c05130

Quotation:

New laser-based technique might assist scientists uncover new puncture-resistant supplies (2023, July 3)

retrieved 4 July 2023

from https://phys.org/information/2023-07-laser-based-method-scientists-puncture-resistant-materials.html

This doc is topic to copyright. Other than any honest dealing for the aim of personal research or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.