Information briefs for the week check out RoboCat and the dawning of the age of general-purpose robots, then the 10-fold productiveness improve from Lockheed’s “good” drilling robotic, then right here’s why robots want higher batteries, adopted by the world’s bin-picking champ at 2700 picks per hour, and at last, Comau additionally leaping into bin-picking sweepstakes with its super-fast choosing cell.

Right here comes the age of general-purpose robots

Making an attempt to get robots and cobots to shortly swap between a number of duties has, till now, been a fancy chore to drag off. Most robots in the present day are special-purpose, in that they carry out a single process effectively till wanted to carry out yet one more process, at which era they require but extra programming.

A general-purpose robotic, with the flexibility to effortlessly automate most any given process when wanted, has lengthy been elusive. Nonetheless, Google’s new RoboCat might be the breakthrough reply, providing up new ranges of intelligence, plus versatile automation, elevated productiveness, and decreased price. In brief, a producer’s dream software.

Created by Google’s UK-based DeepMind subsidiary, RoboCat is a self-improving AI agent that “learns to function completely different robotic arms — and tackle completely different duties — with as little as 100 examples, and it could actually create its personal coaching information to assist sharpen efficiency,” so says DeepMind. A spin-off agent will then have a robotic follow the duty again and again, bodily and nearly — on common, 10,000 instances.

Created by Google’s UK-based DeepMind subsidiary, RoboCat is a self-improving AI agent that “learns to function completely different robotic arms — and tackle completely different duties — with as little as 100 examples, and it could actually create its personal coaching information to assist sharpen efficiency,” so says DeepMind. A spin-off agent will then have a robotic follow the duty again and again, bodily and nearly — on common, 10,000 instances.

The AI behind RoboCat known as Gato, which may course of actions, photographs, and languages in each the actual world and simulated environments. DeepMind fed Gato a coaching set full of robotic arms doing a whole bunch of various duties.

Finally, RoboCat’s library of general-purpose robotic arm actions self-improves to “a dataset of hundreds of thousands of trajectories, from each actual and simulated robotic arms, together with self-generated information.” RoboCat can be taught to function a brand new robotic arm inside a number of hours.

“After observing 1000 human-controlled demonstrations, collected in simply hours, RoboCat may direct a brand new arm dexterously sufficient to select up gears efficiently 86% of the time.”

Not excellent but, however fairly darn good!

Actual world of “good” robots

What does a robotic or cobot imbued with intelligence appear like in the actual world? They’re recognized by their deeds. Early outcomes are displaying “good” robots to be very outstanding in manufacturing, just like the 10-fold productiveness achieve that Lockheed Martin simply skilled.

Lockheed Martin recognized a use case to use AI that targeted on a typical robotics work cell utilized by its manufacturing facility cobots: drilling holes.

Lockheed Martin recognized a use case to use AI that targeted on a typical robotics work cell utilized by its manufacturing facility cobots: drilling holes.

Might AI “empower a business cobot with larger intelligence and understanding of its physique and the duty it’s about to execute whereas making certain the required high quality and tolerances are achieved?”

Xaba’s “artificial mind” xCognition, which makes a speciality of manufacturing, was employed within the manufacturing check. Xaba claims that it’s the developer of the primary AI-driven robotics and CNC machine controller. In contrast to analytical AI used for predictive modeling, Xaba says that its industrial AI focuses on the bodily world. It could mannequin and drive a automobile, a fancy machining middle, and extra complicated industrial functions.

The check consisted of two phases:

The check consisted of two phases:

Section 1: Assessing the cobot’s efficiency in sustaining correct and constant trajectory positioning with and with out Xaba’s xCognition.

Section 2: Performing a set of drilling checks on an aluminum check plate with specified positional tolerances.

The outcomes: Primarily based on the information collected xCognition improved the accuracy and consistency of the business cobot by an element of 10 fold.

Lockheed Martin’s Matthew Galla, an aeronautics functions engineer, remarked: “The check with the xCognition controller permits us to rethink how we are able to speed up innovation in manufacturing.”

Early on, as witnessed within the Lockheed check, the affect of AI in helping manufacturing robots and cobots appears to be nothing wanting gorgeous.

Higher batteries for robots

A hearth at an Ocado warehouse, begun by an automatic cellular robotic (AMR) recharging its battery, burned for 3 days, dropping within the course of 300,000 buyer orders and 1100 robots for a complete of $48 million in damages.

The warehouse burned to the bottom within the three-day blaze after a fault in a battery charging unit set hearth to the plastic lid of one of many grocery-picking robots.

The warehouse burned to the bottom within the three-day blaze after a fault in a battery charging unit set hearth to the plastic lid of one of many grocery-picking robots.

Some stories alleged that robots had been nonetheless transferring when firefighters arrived, hindering their potential to manage the blaze.

It wasn’t an remoted incident. One other battery-related hearth began when three warehouse robots collided. As soon as ignited, a robotic’s lithium-ion batteries are extraordinarily troublesome to extinguish. As AMRs proliferate within the accelerated tempo of automating warehouses, the incidence of extra such hearth risks turns into distinctly potential.

And warehouse fires aren’t the one downside plaguing a robotic’s lithium-ion batteries nor are warehouses the one hassle spots.

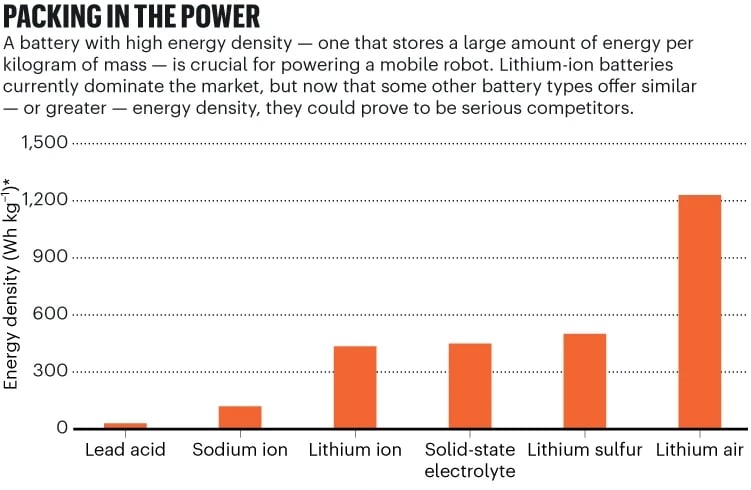

A current article within the journal Nature, Robots Want Higher Batteries, cites the cellular robots—on wheels, treads, tracks, or on two or 4 legs—unable to tolerate large batteries. Boston Dynamics sells a four-legged dog-size robotic referred to as Spot that weighs about 32 kg — one-eighth of which is batteries, which want recharging after solely 90 minutes.

“Vitality density continues to be fairly removed from the facility we want for robotics,” says Ravinder Dahiya, {an electrical} engineer specializing in robotics at Boston’s Northeastern College.

Future ahead, lithium-ion expertise is getting older quickly, with “much less and fewer room for enchancment,” says Richard Schmuch, a chemist at Germany’s Fraunhofer Analysis Establishment for Battery Cell Manufacturing. “Lithium itself is uncommon and costly. The identical is true for cobalt, one other essential ingredient which may make as much as 20% of the burden of the cathode in lithium-ion batteries for electrical autos.”

Like lithium, sodium is an alkali metallic, and the chemistry of the 2 is so related that researchers have pursued sodium-ion batteries as a manner across the issues with lithium-ion. Sodium in seawater and salt deposits is extra simply harvested, which negates the supply-chain issues arising from the fee and shortage of lithium.

China’s Modern Amperex Know-how (CATL) in Ningde — the world’s main producer of lithium-ion batteries for electrical autos — rolled out the primary era of its sodium-ion battery; and this April, Chery Car in Wuhu, China, introduced plans to put in CATL sodium-ion batteries in its automobiles.

Advocates of the sodium-ion battery say it presents the perfect prospects for stopping the doubtless lethal fires seen with lithium batteries, in addition to for bettering vitality density and lowering prices.

Higher batteries for robots could also be simply across the nook.

Blitz choosing at 2700 per hour

Schmalz, the German vacuum gripper developer, will need to have gotten a bit uninterested in seeing bin-picking cells working at much less of a choosing velocity than it deemed acceptable. So, it developed its personal, and within the course of, set a brand new velocity document for bin choosing. Name it blitz choosing at 2700 picks per hour!

Schmalz blitz choosing bests closest rival Pickit (2100 per hour) by 600. Each are effectively past the common of a pick-and-place robotic’s price of 300 per hour.

Schmalz blitz choosing bests closest rival Pickit (2100 per hour) by 600. Each are effectively past the common of a pick-and-place robotic’s price of 300 per hour.

With the common variety of objects in an e-commerce order barely over three, the Schmalz choosing champ betters Pickit by 200 orders per hour.

In collaboration with German integrator, Körber, Schmalz constructed its personal piece-picking cell utilizing a pair of SCARA robots (Körber constructed the conveyor system).

“The robots work concurrently and may change their grippers inside a second, relying on whether or not they’re dealing with containers, vials, or luggage. Two 3D cameras examine the field after every choose.

“Software program analyses this enter, calculates, and controls the subsequent grip. A number of gripping algorithms function in parallel to attain the perfect choosing efficiency. The system makes use of five-axis grippers that may attain into all corners of a crate.”

Schmalz developed the choose accelerator “equipment” that optimizes the interplay between grippers, robots, cameras, and choosing software program referred to as the Schmalz Answer Equipment.

Comau joins bin-picking hunt

Milan-based automation and robotic developer Comau has additionally joined the bin-picking race with its MI.RA Picker, which makes use of two high-resolution laser sensors and a central digicam, mixed with digital simulation instruments and predictive algorithms, to optimize path administration and obtain collision-free trajectories.

Milan-based automation and robotic developer Comau has additionally joined the bin-picking race with its MI.RA Picker, which makes use of two high-resolution laser sensors and a central digicam, mixed with digital simulation instruments and predictive algorithms, to optimize path administration and obtain collision-free trajectories.

Curiously, the MI.RA Picker can be utilized with any make of robotic, bin or gripper to acknowledge, find and grasp as much as 40 randomly positioned objects each minute, which tallies as much as 2400 picks per hour. That’s a velocity the betters Pickit, but nonetheless falls wanting the Schmalz industry-leading choosing equipment at 2700 picks per hour.

![]()