Industrial 3D printing supplies producer 6K Additive has introduced a partnership with France-based industrial metallic 3D printing specialist Z3DLab. This collaboration will middle across the manufacturing of Z3DLab’s superior ZTi titanium alloys vary.

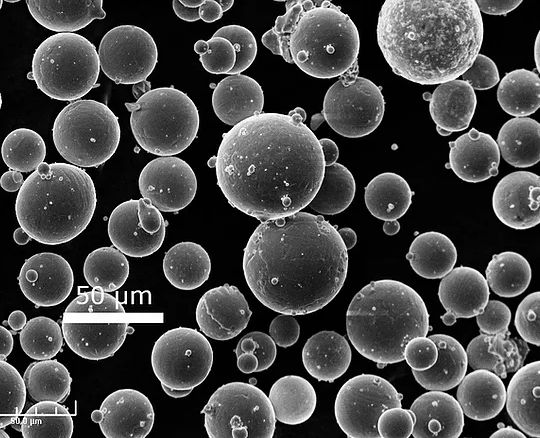

6K Additive will make the most of its UniMelt expertise to course of the ZTi alloys, producing spherical, dense powders to be used in additive manufacturing. This course of is alleged to ship as much as 100% yield, growing the business viability of latest materials manufacturing. It’s claimed that this collaboration will drive the manufacturing of latest superior 3D printing supplies to be used in medical implant and aerospace functions.

“Our ZTM14N materials is exclusive for the medical implant {industry} and has great progress alternative within the area. Nonetheless, we can not afford to undergo the yield loss that’s typical within the atomization course of throughout manufacturing. We can be burdening the price unnecessarily for our clients,” commented Z3DLab President Dr Madjid Djemai.

“6K Additive’s UniMelt delivers the required excessive yields of extremely spheroidized powder that allows us to cost-effectively ship our materials to the market. This partnership advantages not solely 6K Additive and Z3DLab but additionally the shoppers we serve,” added Djemai, who can be trying ahead to future initiatives within the aerospace sector.

6K Additive’s UniMelt system

6K Additive’s UniMelt system makes use of a microwave plasma course of, able to changing chemistry machines milling, turnings, and recycled feedstock into industry-ready metallic 3D printing powders. UniMelt’s extremely uniform and exact plasma zone, with zero contamination, ends in excessive throughput manufacturing of a variety of additive manufacturing supplies.

“Our UniMelt manufacturing scale powder manufacturing platform can course of a near-infinite vary of alloys due to its microwave plasma power supply and unparalleled controllability,” commented Francois Bonjour, European Gross sales Director for 6K Additive.

Key to the UniMelt course of is its skill to make use of scrap, revert or used powder as feedstock. This eliminates the necessity for virgin materials extraction, whereas concurrently producing the next high quality remaining powder in comparison with conventional atomization strategies. Z3DLab’s alloys can in the end be reprocessed on this method, producing a round financial system for high-performance, high-value alloys.

“As an organization devoted to sustainability, we consider that the way forward for AM lies in high-performance alloys that may make lighter, stronger parts with longer lifespans,” added Bonjour. “It solely is smart for Z3DLab and 6K Additive to accomplice to convey such an revolutionary materials to the market with the standard and price mannequin to make it profitable commercially.”

Z3DLab’s ZTi Powder vary

The Z3DLab ZTi-Powder vary consists of supplies optimized for each powder mattress fusion (PBF) and directed power deposition (DED) 3D printers. These powders are stated to incorporate specialised formulations that supply improved ductility, put on resistance and warmth oxidation relative to Ti64

Supplies within the ZTi-Powder vary embody ZTP10, a powder combining excessive power and ductility with excessive fatigue and friction resistance; ZTP20Z, a PBF powder which mixes Ti64 and Zirconium; and ZTP-DeD, an enhanced Ti64 powder designed for the upkeep restore and operations (MRO) {industry}.

Moreover, the ZTi-Med alloys vary consists of ZTM14N. This biocompatible titanium ternary alloy is designed to take care of strength-ductility ratio, whereas sustaining optimum elasticity.

ZTM14N presents an particularly low elastic modulus of 38 GPa. This matches the elastic modulus vary of human bone (~5-30 GPa), making ZTM14N particularly well-suited to medical implant functions. Certainly, medical implants manufactured with this alloy possess an improved resistance to inflammatory species by virtually 10 instances, in comparison with various titanium alloys with a Bone Interference Contact (BIC) worth of 95%.

Titanium 3D printing

Titanium 3D printing is definitely a rising space inside business additive manufacturing.

Earlier this month, Montreal-based metallic powder producer and plasma torch specialist PyroGenesis reported that it had obtained an order for 5 metric tonnes (5,000 kg) of plasma atomized titanium metallic powders utilized in 3D printing. Although the precise id of the consumer has not been disclosed, it has been confirmed to be a US-based superior supplies firm. Furthermore, the consumer has provisionally ordered an extra six tonnes (6,000kg) titanium powders primarily based on its evaluation of demand for extra powders.

PyroGenesis VIce President Massimo Dattilo outlined that that is the primary “By-The-Tonne” business order the corporate has obtained for its atomized powder titanium metallic powders. “This represents our full entrance into the titanium metallic powders market,” Dattilo added.

Elsewhere, it was lately introduced that US-based titanium developer IperionX will provide Ford with 100% recycled low-carbon titanium. This settlement kinds a part of Ford’s initiative to scale back its carbon footprint, having dedicated to attain carbon neutrality by 2050.

“We’re proud to accomplice with Ford to speed up the deployment of a sustainable, round titanium provide chain for the worldwide automotive market,” commented IperionX CEO Taso Arima. “Our low-carbon titanium metallic is uniquely made with 100% recycled titanium and may considerably enhance automotive provide chains through the use of high-strength titanium parts with almost half the burden of metal.

Subscribe to the 3D Printing Business publication to make sure you sustain with the newest 3D printing information. You may as well comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing {industry}? Go to 3D Printing Jobs to view a collection of out there roles and kickstart your profession.

Featured picture exhibits DNA dental implants 3D printed utilizing ZTM14N powder. Photograph through 6K.