A sustainable technological revolution goals to scale back carbon footprint and dependence on uncommon supplies by superior manufacturing and recycling options.

Natural electronics possess the potential to play a big function in decarbonization efforts whereas concurrently decreasing the demand for scarce and invaluable uncooked supplies. To realize this, it’s essential to advance manufacturing processes and set up technical options for recycling from the early phases, together with the laboratory part.

Supplies scientists from Friedrich-Alexander College (FAU), together with researchers from the UK and the US, revealed a name to undertake this round technique within the famend journal “Nature Supplies” in June 2023. Natural digital elements, like photo voltaic modules, provide flexibility and numerous functions in comparison with crystalline supplies. Their carbon-based photoactive substances cut back reliance on uncommon and dear supplies like iridium, platinum, and silver. They’re particularly booming in Natural Gentle-Emitting Diode (OLED) know-how, primarily for TV and laptop screens.

Extra environment friendly synthesis and extra strong supplies

Creating natural electronics entails utilizing new supplies and environment friendly manufacturing processes to scale back power and prices. The researchers have proposed eco-friendly strategies like water-based deposition and inkjet printing to interchange high-energy vacuum deposition. The problem lies to find non-toxic solvents and growing supplies for inkjet printing, probably changing treasured metals in OLED screens. Enhancing materials sturdiness is essential, as advanced encapsulation protects carbon layers and reduces weight. Strong materials combos can considerably save power, weight, and assets.

Planning the recycling course of within the laboratory

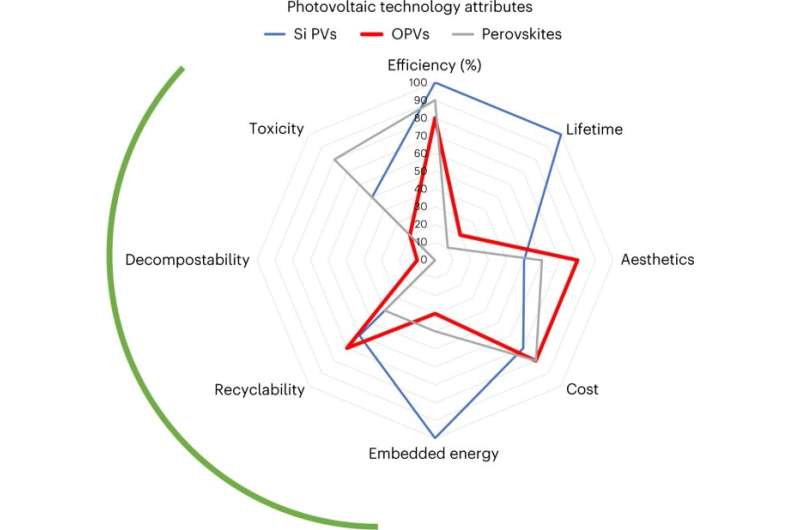

To evaluate the environmental influence of natural electronics precisely, all the product lifecycle have to be thought of. Whereas natural photovoltaic programs have a decrease output than silicon modules, they emit 30% much less CO2 throughout manufacturing. Most effectivity isn’t every little thing; fewer manufacturing steps and a smaller environmental footprint could also be important. The shorter lifespan of natural modules is relative as a consequence of difficulties in recycling silicon-based modules. Biocompatibility and biodegradability are essential for product and packaging design. Recycling issues ought to begin within the laboratory, utilizing recyclable substrates and multilayer designs for straightforward separation and recycling. Adopting a cradle-to-cradle strategy is significant for establishing natural electronics within the renewable power transition.

Reference: Iain McCulloch et al, Sustainability issues for natural digital merchandise, Nature Supplies (2023). DOI: 10.1038/s41563-023-01579-0