Researchers from RMIT College and the College of Sydney have developed a brand new class of sturdy, ductile, tunable, and sustainable titanium alloys. This analysis was carried out in collaboration with Hong Kong Polytechnic College and Swedish software program developer Hexagon’s Manufacturing Intelligence division.

Titanium alloys are extremely helpful supplies, and are prized for his or her power, low weight, and resistance to corrosion and excessive temperatures. Nonetheless, historically manufactured titanium alloys are costly to supply.

This new analysis is alleged to supply potential for a brand new class of sustainable and low cost high-performance titanium alloys to be used in aerospace, biomedical, chemical engineering, area, and vitality purposes. The group built-in alloy and 3D printing course of design to develop their new titanium alloys, that are 3D printed from steel powders utilizing Laser Directed Power Deposition (L-DED).

In keeping with lead researcher Professor Ma Qian from RMIT, the analysis group embedded round economic system into their design. These novel alloys could be produced from waste merchandise and low-grade supplies, with out the necessity for costly components corresponding to vanadium and aluminum. As an alternative, oxygen and iron, that are each low cost and ample, are used.

“Reusing waste and low-quality supplies has the potential so as to add financial worth and cut back the excessive carbon footprint of the titanium business,” commented Qian.

Lead creator Dr Tingting Music from RMIT claimed that the group is “at the beginning of a serious journey, from the proof of our new ideas right here, in direction of industrial purposes”.

“There are grounds to be excited – 3D printing provides a basically completely different method of constructing novel alloys and has distinct benefits over conventional approaches. There’s a possible alternative for business to reuse waste sponge titanium-oxygen-iron alloy, ‘out-of-spec’ recycled high-oxygen titanium powders or titanium powders constituted of high-oxygen scrap titanium utilizing our strategy,” added Music.

The group’s analysis paper titled ‘Sturdy and ductile titanium-oxygen-iron alloys by additive manufacturing’, has been printed within the journal Nature.

Creating new 3D printed titanium alloys

The group’s alloys encompass a combination of two types of titanium crystals, alpha-titanium part and beta-titanium part, known as Ti-6Al-4V. Every kind corresponds to a selected association of atoms.

The commonest titanium alloy, Ti-6Al-4V has been historically produced utilizing 6% aluminum and 4% vanadium, and makes up over 50% of all the titanium market. This new analysis replaces aluminum and titanium with oxygen and iron. Along with being available and cheap, these parts are two of essentially the most highly effective stabilizers and strengtheners of alpha- and beta-titanium phases.

Historically, titanium alloys incorporating excessive ranges of titanium and oxygen have confronted challenges which have hindered their improvement and adoption.

“One problem is that oxygen – described colloquially as ‘the kryptonite to titanium’ – could make titanium brittle, and the opposite is that including iron might result in severe defects within the type of giant patches of beta-titanium,” mentioned Qian.

L-DED 3D printing, a course of typically used for manufacturing giant and sophisticated elements, allowed the researchers to beat these challenges.

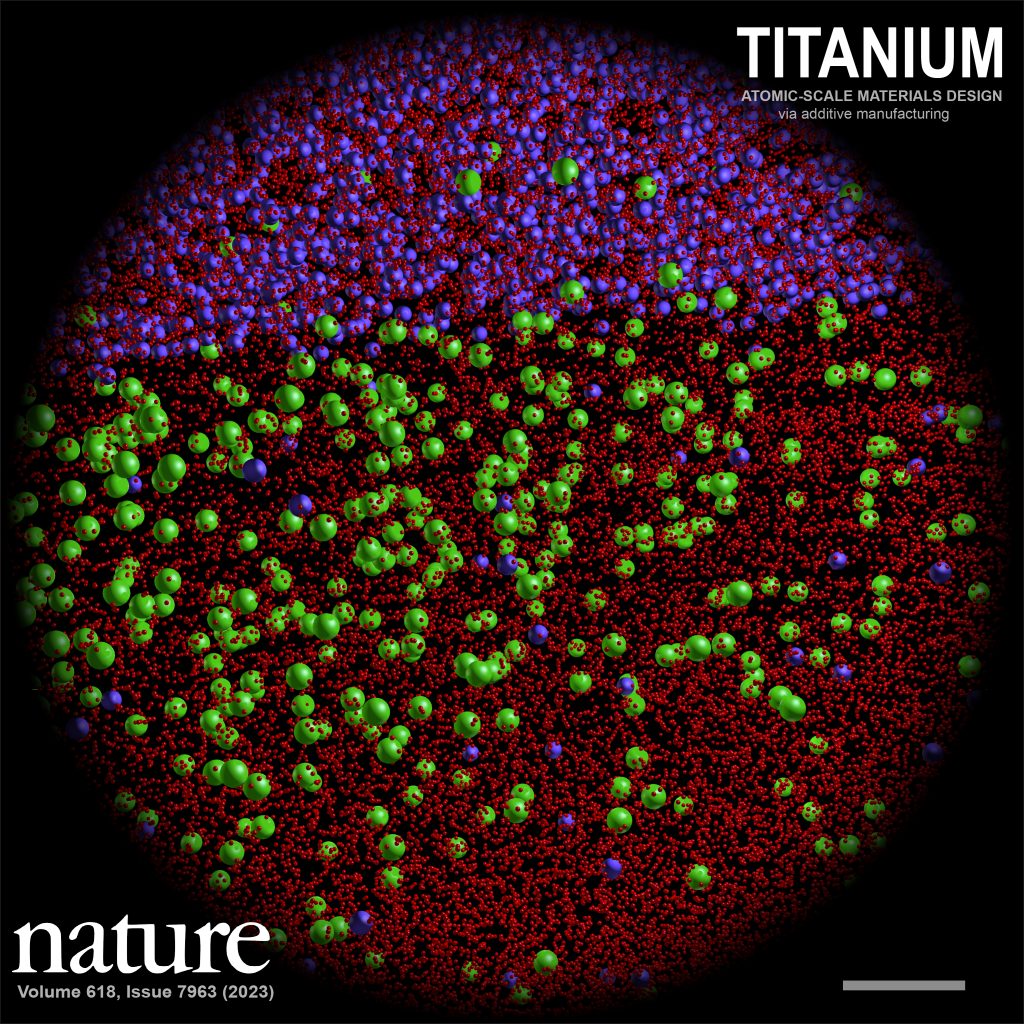

Utilizing L-DED allowed the group to tune the mechanical properties of the alloys. The scientists produced nanoscale-sized titanium crystals throughout the alloy, fastidiously controlling the distribution of oxygen and iron atoms. This resulted in some particular elements of the alloy being sturdy, and others which can be ductile, guaranteeing the fabric just isn’t brittle beneath stress.

Utilizing the DED module in Hexagon’s Simufact Welding program, the group 3D printed and examined a sequence of those configurations. After testing, the researchers discovered that their alloys might rival the ductility and power of different industrial titanium alloys.

“The essential enabler is the distinctive distribution of oxygen and iron atoms inside and between the alpha-titanium and beta-titanium phases,” defined Professor Simon Ringer, co-lead researcher from the College of Sydney.

“We’ve engineered a nanoscale gradient of oxygen within the alpha-titanium part, that includes high-oxygen segments which can be sturdy, and low-oxygen segments which can be ductile permitting us to exert management over the native atomic bonding and so mitigate the potential for embrittlement.”

Developments in 3D printing alloys

This isn’t the primary time 3D printing has been used within the improvement of steel alloys. Final 12 months, researchers from RWTH Aachen College’s Chair for Digital Additive Manufacturing (DAP) used Excessive Excessive-Pace Laser Materials Deposition (EHLA) 3D printing to develop new alloys for laser powder mattress fusion (PBF).

EHLA was initially developed in 2017 as Fraunhofer ILT’s tackle high-volume directed vitality deposition (DED). RWTH’s investigation in contrast each printing applied sciences’ course of traits, yielding promising outcomes almost about the transferability of their materials capabilities. From their findings, the DAP group deduced that it might qualify EHLA as a fast alloy improvement platform for PBF 3D printing.

Elsewhere, NASA, the US Nationwide Aeronautics and House Administration, have developed a novel steel 3D printing alloy to be used in high-performance aerospace methods. Known as GRX-810, this new materials is an instance of an oxide dispersion strengthened (ODS) alloy, a steel containing nanoscale oxide particles. This alloy is reportedly extremely sturdy and sturdy, able to withstanding temperatures of over 1090°C (2000°F).

“The nanoscale oxide particles convey the unbelievable efficiency advantages of this alloy,” commented Dale Hopkins, deputy challenge supervisor of NASA’s Transformational Instruments and Applied sciences challenge.

Subscribe to the 3D Printing Trade e-newsletter to make sure you sustain with the most recent 3D printing information. You too can comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing business? Go to 3D Printing Jobs to view a choice of accessible roles and kickstart your profession.

Featured picture exhibits an Atomic-scale microstructure throughout an alpha-beta interphase interface from a brand new alloy 3D-printed by the group utilizing laser directed vitality deposition. Picture through Ma Qian Simon Ringer and colleagues.