When Ange Nzihou, an skilled in changing society’s waste into precious merchandise, visited Princeton in 2022, he introduced with him a way to remodel waste biomass into graphene, a cloth with many makes use of from batteries to photo voltaic cells. He knew his strategy utilizing a unhazardous iron catalyst supplied benefits over present strategies counting on hazardous chemical substances, valuable metals or fossil fuels.

There was only one downside: Nzihou did not precisely understand how the method labored.

“In my work as a chemical engineer, I am usually within the remaining properties of supplies and the way they are often utilized to the true world,” stated Nzihou, a distinguished professor of chemical engineering at IMT Mines Albi—CNRS in France who visited Princeton by the Fulbright Visiting Scholar Program. “However if you wish to optimize the properties of the supplies you produce, it’s important to perceive what occurs on the nano and atomic scales to deliver concerning the transformation.”

That is the place Claire White, affiliate professor of civil and environmental engineering and the Andlinger Heart for Power and the Setting, got here in to assist.

As Nzihou’s college host, White contributed her experience within the nano- and atomic-scale characterization of supplies to uncover the mechanism that enabled iron to assist convert waste biomass into graphene.

The outcome was not solely two papers, the primary revealed in ChemSusChem and the opposite in Utilized Nano Supplies, that element the mechanism and promise of utilizing iron as a catalyst to remodel waste biomass, comparable to wooden chips and different cellulose-rich biomass, into value-added carbon supplies. It was additionally a launchpad for continued collaboration between the 2 teams, one which mixed every group’s experience so as to add new dimensions to their analysis applications.

A discovery of nano-scale proportions

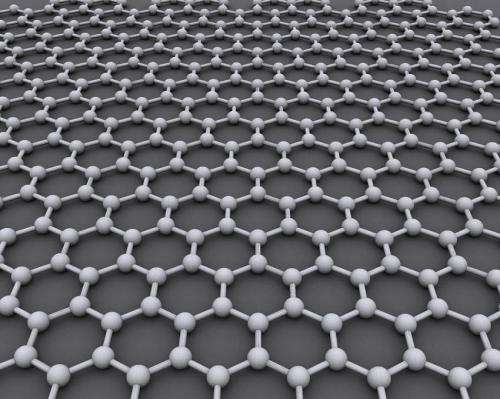

Graphene, a sheet of pure carbon only one atom thick, is often made through chemical vapor deposition, a course of incessantly used within the semiconductor trade to supply uniform coatings. Nevertheless, Nzihou stated chemical vapor deposition usually hinges on hazardous chemical substances and costly applied sciences. Likewise, he stated options for graphene manufacturing usually make use of poisonous or cost-prohibitive supplies, in addition to using petroleum-based sources.

Seeking an environmentally pleasant approach to produce graphene, Nzihou and White turned to underused sources of biomass as a beginning materials for the method. Sadly, most of that biomass is wealthy in cellulose, an ample polymer discovered within the cell partitions of crops. Cellulose has confirmed troublesome to transform into extremely ordered carbon supplies comparable to graphene with out using poisonous or uncommon earth steel catalysts due to the construction and association of its chemical bonds.

However Nzihou discovered that an iron oxide catalyst might do the trick. By inserting the iron into the biomass and heating it in an oxygen-limited surroundings by a course of often known as carbonization, Nzihou demonstrated it was potential to remodel cellulose-rich biomass right into a remaining materials with intensive areas of ordered graphene sheets.

“Ange had proven that it was potential to make use of iron as a catalyst,” White stated. “However the true query was in making an attempt to grasp how iron was offering this catalytic habits.”

White turned to her experience in atomic and nano-scale characterization for the reply. Utilizing strategies comparable to X-ray complete scattering, Raman spectroscopy, transmission electron microscopy, and magnetic measurements, the researchers discovered that over the course of the heating course of, the iron oxide catalyst first broke all the way down to kind nanoparticles throughout the biomass. Because the cellulose-rich biomass started to dissolve at greater temperatures, it precipitated as layers of graphene sheets onto the floor of the iron particles.

“We had been truly in a position to observe this ordered shell of carbon atoms that shaped round these iron nanoparticles throughout the course of,” White stated.

Apparently, Nzihou and White discovered that a couple of bigger iron nanoparticles supported extra intensive areas of graphene formation than many smaller ones, a useful clue that might inform future efforts to scale up the method of turning waste biomass into graphene. The researchers are additionally persevering with to refine the method to extend the scale of the pure graphene areas whereas lowering the variety of defects within the remaining materials.

“Now that now we have an understanding of the mechanism, we are able to work out how you can enhance the method and optimize the properties of the graphene sheets in comparison with the standard chemical vapor deposition technique, and even think about methods to scale it within the close to future,” Nzihou stated. “As a result of on the finish of the day, our work is all about growing eco-friendly superior carbon supplies whereas closing the carbon loop and mitigating carbon dioxide emissions.”

A launchpad for fruitful collaborations

The researchers stated that the venture allowed them to leverage each other’s experience to advance the sphere of sustainable carbon utilization, and the preliminary partnership has since dovetailed into a number of ongoing analysis initiatives.

“It has been an thrilling collaboration,” stated White. “I might have by no means seen myself engaged on these sustainable carbon supplies, however these initiatives with Ange have supplied a chief alternative to develop my work and add new dimensions to my analysis.”

For Nzihou, his time as a visiting Fulbright Scholar turned out to be solely a preview of what’s to come back. He’ll return to the Andlinger Heart in March 2024 as a Gerhard R. Andlinger Visiting Fellow to proceed exploring methods to remodel underused sources of biomass into superior carbon supplies with particular properties for purposes starting from agriculture to vitality storage and CO2 sequestration.

With White, he plans to broaden the scope of his work by uniting the experience of different Princeton college members comparable to Craig Arnold, Michele Sarazen and Rodney Priestley to develop a technique for sustainable carbon utilization. He additionally goals to collaborate with the Princeton Plasma Physics Laboratory (PPPL) to discover using plasmas to energy numerous manufacturing processes.

The primary paper, “Synthesis and Development of Inexperienced Graphene from Biochar Revealed by Magnetic Properties of Iron Catalyst,” was revealed Nov. 2022 in ChemSusChem. The second paper, “Iron Nanoparticles to Catalyze Graphitization of Cellulose for Power Storage Functions,” was revealed Feb. 2023 in Utilized Nano Supplies.

Extra data:

Amel C. Ghogia et al, Synthesis and Development of Inexperienced Graphene from Biochar Revealed by Magnetic Properties of Iron Catalyst, ChemSusChem (2022). DOI: 10.1002/cssc.202201864

Lina M. Romero Millán et al, Iron Nanoparticles to Catalyze Graphitization of Cellulose for Power Storage Functions, ACS Utilized Nano Supplies (2023). DOI: 10.1021/acsanm.2c05312

Supplied by

Princeton College

Quotation:

Engineers reveal the secrets and techniques behind inexperienced graphene (2023, July 13)

retrieved 13 July 2023

from https://phys.org/information/2023-07-reveal-secrets-green-graphene.html

This doc is topic to copyright. Aside from any truthful dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for data functions solely.