Scrona, a Swiss inkjet printing pioneer, is popping its expertise in direction of MEMS-based 3D printing, for the manufacturing of MicroLED shows. Not like conventional inkjet applied sciences, Scrona’s electrostatic inkjet printing makes use of electrical forces to tug droplets from the nozzle, leading to greater effectivity and the power to print with a broader vary of supplies, together with extremely viscous inks. Their new expertise gives printing resolutions as little as 0.5µm, making it particularly appropriate for digital purposes with tiny elements.

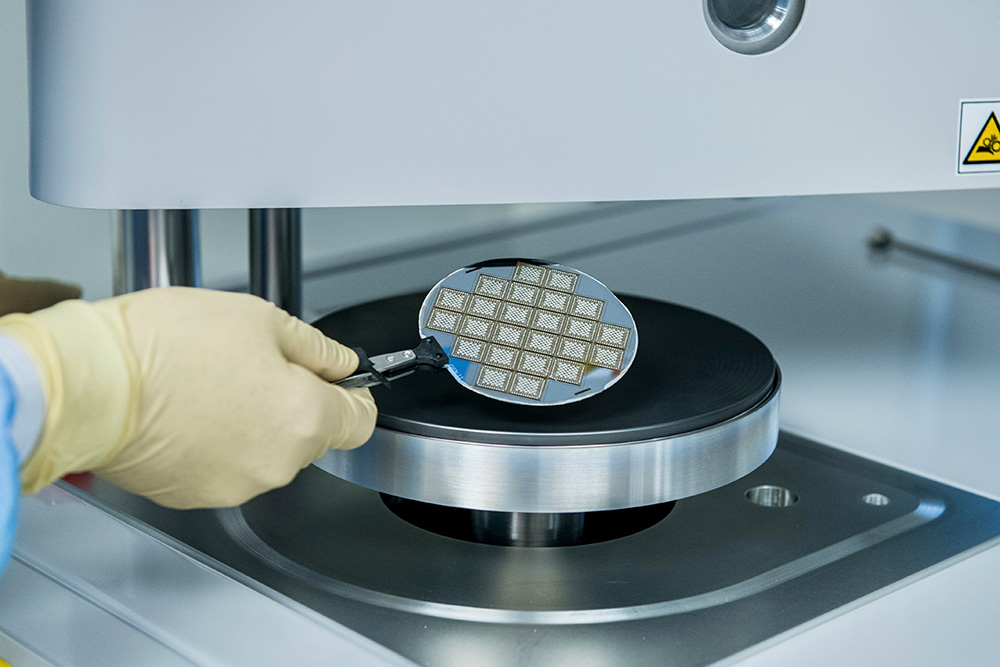

The center of Scrona’s print head expertise is its proprietary MEMS chip, which has undergone over a decade of growth. This chip permits for the formation of 1000’s of nozzles on a small space, enabling high-volume manufacturing capabilities. The precision achieved by the expertise is outstanding, with placement accuracy higher than 1µm and the power to scale as much as bigger arrays with as much as 128 nozzles.

Scrona’s purpose is to convey practical printing to areas the place additive manufacturing is extremely beneficial. By leveraging MEMS silicon and implementing digital management functionality, they’ve overcome the challenges of particular person nozzle management and lowered the excessive voltages required for operation. This has enabled using 1000’s of nozzles and unlocked manufacturing economics.

The scalability of the print heads is a key issue of their compatibility with manufacturing necessities. The present prototype options 10 nozzles, however Scrona plans to develop print heads with 1000 nozzles, paving the way in which for even sooner and extra environment friendly printing processes. The corporate can also be targeted on bettering decision and precision, catering to the calls for of superior packaging, back-end processes, and printing supplies resembling safety and encapsulation.

One vital benefit of Scrona’s expertise is the absence of thermal load throughout patterning, permitting using supplies like perovskites. The corporate has additionally developed an lively solvent removing system to stop condensation on the print head, addressing the challenges of high-speed, high-volume manufacturing.

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t overlook to enroll in our weekly additive manufacturing publication to get all the newest tales delivered proper to your inbox.