An 18-month collaboration with the European Area Company has resulted in a profitable mission exploring additive manufacturing for the lunar atmosphere, says steel 3D printing firm Incus.

The joint effort alongside prime contractor OHB System AG got down to set up the opportunity of a zero-waste workflow utilizing lunar assets and scrap supplies recovered from outdated mission or satellite tv for pc particles, finally contaminated by lunar mud, to 3D print spare components utilizing Incus’ Lithography-based Metallic Manufacturing (LMM).

The mission’s overarching ambition is to point out the feasibility of making a sustainable human base on the moon. Naturally, the concept of leveraging lunar manufacturing to sooner or later assist a human habitat is taken into account a problem because of the environment, gravity, temperature, radiation, and the potential contamination of moon mud.

Dr. Martina Meisnar, Supplies and Processes Engineer at ESA defined: “Contemplating the problem of bringing people again to the moon and constructing a base, the subject of in-situ useful resource utilisation (ISRU) is gaining important momentum. Tasks like this, not too long ago accomplished by Incus and mission companions, reveal that manufacturing strategies like LMM are excellent candidates to assist such an endeavour.”

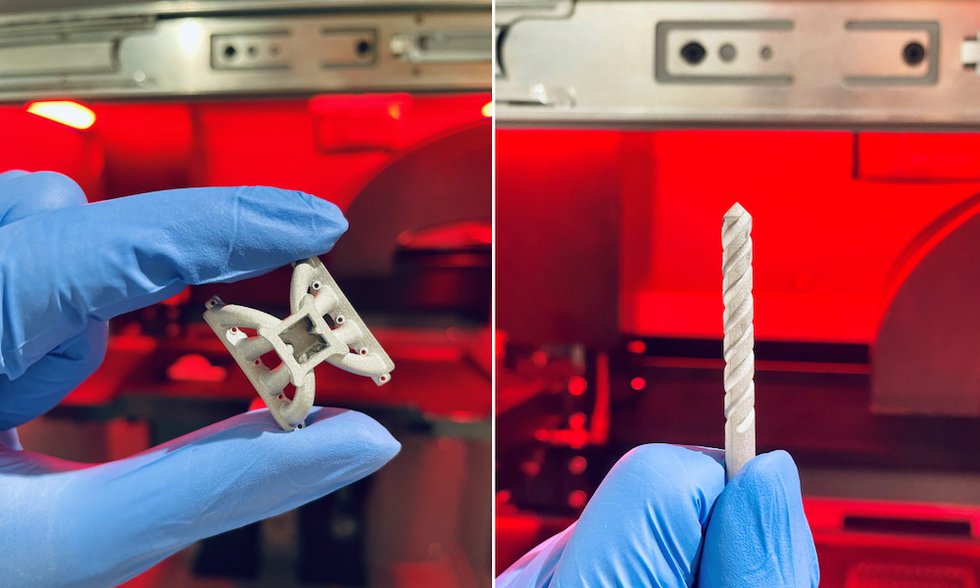

Incus claims components printed on its Hammer Lab35 in recycled titanium powder maintained ‘correct half high quality’, and demonstrated a excessive degree of power, corresponding to steel injection moulded titanium components requirements (1000-1050 MPa).

“This mission has confirmed that LMM know-how is ready to use recycled powder for the feedstock materials and supply sustainable zero-waste workflow,” stated Incus CEO Dr. Gerald Mitteramskogler. “We count on that additional developments in steel recycling applied sciences will open the way in which to steel supplies with extra settled sintering processes for the lunar atmosphere.”

In contrast to direct steel laser AM processes, Incus’ LMM know-how doesn’t depend on using gas-atomised powders or assist constructions, and as an alternative makes use of a paste or suspension as feedstock. LMM is due to this fact in a position to print scrap metals utilizing pre-mixed feedstock. The mission additionally included the event of a inexperienced binder and the optimisation of pre- and post-processing steps to print and check totally different demonstrators for future lunar functions. It additionally explored potential in situ contamination through the use of lunar regolith simulant.

Francesco Caltavituro, System Engineer for the mission at OHB stated: “Using native lunar assets, in addition to the recycling of outdated spacecraft, are important for a sustainable and Earth-independent moon base. Via this mission, it was confirmed that the LMM know-how is ready to use recycled powder sources as feedstock materials. Moreover, it was demonstrated that contaminations for the powder sources through the use of lunar regolith simulant are manageable, particularly from the attitude of the printing course of. With these features in thoughts, in addition to the longer term challenges already foreseen and anticipated, upcoming analysis and improvement will be capable to proceed and open-up additional the way in which in direction of a sustainable moon settlement lastly launched from Earth dependency.”

Dr. Martin Schwentenwein, Head of Materials Improvement at Lithoz, the ceramics additive manufacturing specialist which Incus spun out of in 2019, stated the mission confirmed that “lithography-based AM methods are among the many most promising candidates to let 3D printing in house grow to be a actuality sooner or later.”