Scientists from Chinese language Academy of Sciences Ningbo Institute of Supplies Know-how and Engineering, Nationwide Bodily Laboratory (U.Ok.), The College of Manchester (U.Ok.) and Nationwide College of Singapore have developed a brand new strategy, revealed in Worldwide Journal of Excessive Manufacturing, to manufacture a particularly designed wideband microwave absorption metamaterial with well-controlled electrical and magnetic traits on a polyethylene terephthalate (PET) substrate utilizing ultraviolet (UV) laser irradiation.

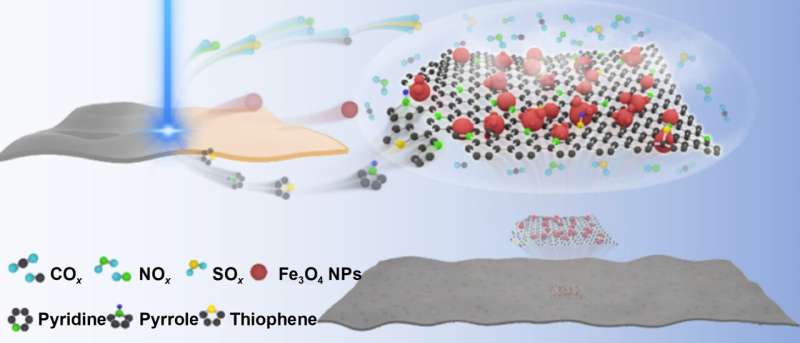

The method includes utilizing a UV laser to exactly management the traits of 2D sample on a specifically formulated donor materials which upon interactions with the laser beam types magnetic particle imbedded graphene, leading to a extremely purposeful ultra-wideband (1.56–18.3GHz) and vast angle microwave absorption metamaterial, which might doubtlessly be utilized in automated and roll-to-roll mass manufacturing.

This analysis presents a one-step laser synthesis technique that permits spontaneous conversion of PBI ink to 3D nanostructured graphene and the discount of a liquid ion precursor to Fe3O4 magnetic nanoparticles. Furthermore, a few of these ensuing distinctive structural options exhibited superior absorption efficiency in comparison with many of the MMAs reported beforehand, and the method, carried out in ambient ambiance, solely requires donor coating and laser irradiation with out the necessity for post-treatment.

“The exact sheet resistance management of laser induced graphene(LIG) with solely 5% deviation was achieved by acceptable laser photoreaction and thermal reactions, fairly than fastened crystal size of LIG with uncontrollable sheet resistance. Magnetic Fe3O4 nanoparticles have been shaped utilizing a exactly managed laser-induced photo-thermal response, fairly than an oxidized nano-mixture,” mentioned Dr. Yihe Huang, the primary creator of this text and Affiliate Researcher from Ningbo Institute of Industrial Know-how (NIMTE), Chinese language Academy of Sciences.

“The laser-controlled fabrication course of resulted in a flat floor laminate, with even distribution of magnetic and electrical supplies. Because of this, the measured outcomes of the microwave absorber intently matched the unique design.”

“Via the employment of a sandwich construction, we’ve got crafted superior multilayer absorbers that match air impedance over the broadest doable working frequency vary, whereas upholding a small relative thickness. The primary layer, that includes a softly contoured round sample, contributes to an extension within the working frequency. The mixing of round and sq. patterns within the multilayer construction attains adverse permittivity metamaterial properties, attaining a noteworthy good absorption (absorptivity of 99%) greater than as soon as inside the working frequency vary,” mentioned Mr. Yize Li, Ph.D. Candidate on the College of Manchester.

The conductive laminates that have been fabricated by laser method present remarkably uniform sheet resistance distribution. The sheet resistance variation is sort of an order of magnitude lower than that of display screen or spray printing. This benefit helped the ultimate efficiency of the laser fabricated microwave absorber match its unique design.

Dr. Kewen Pan, Affiliate Researcher at NIMTE mentioned, “After appropriate tuning, the microwave absorber achieved a mean absorption coefficient within the vary of 97.2% to 97.7% over a large bandwidth and vary of incident angles. Primarily based on my literature search, this microwave absorber has the most effective bandwidth to thickness ratio ever reported.”

Professor Lin Li, Director of Laser Excessive Manufacturing at NIMTE and fellow of the Royal Academy of Engineering, commented, “This analysis has achieved a serious breakthrough within the direct manufacturing of conformal microwave absorber on complicated constructions, which was made doable by the simultaneous formation and tuning {of electrical} and magnetic properties of laser patterned supplies on versatile and curved substrates.

“With the very best relative bandwidth and lowest thickness supplies until date, this technique introduces a brand new avenue for the large-scale manufacturing of metamaterials for microwave absorption purposes in aviation, electromagnetic interference (EMI) suppression, and 5G expertise.”

Extra data:

Yihe Huang et al, A direct laser-synthesized magnetic metamaterial for low-frequency wideband passive microwave absorption, Worldwide Journal of Excessive Manufacturing (2023). DOI: 10.1088/2631-7990/acdb0c

Supplied by

Worldwide Journal of Excessive Manufacturing

Quotation:

Scientists presents a one-step laser synthesis technique for fabricating wideband microwave absorption metamaterial (2023, July 13)

retrieved 16 July 2023

from https://phys.org/information/2023-07-scientists-one-step-laser-synthesis-method.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is offered for data functions solely.