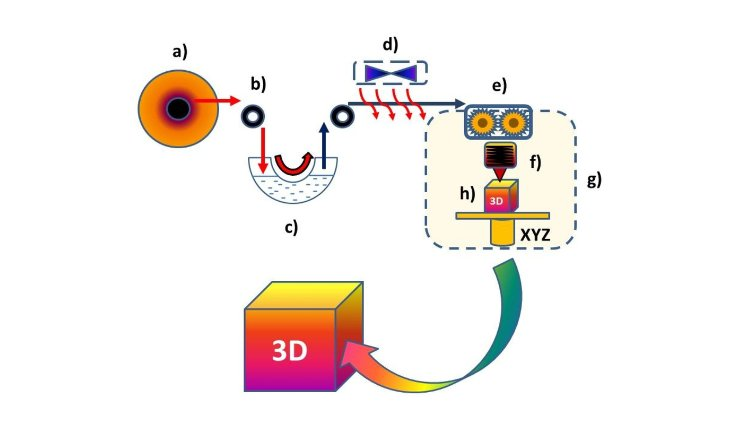

Sygnis SA, a Polish manufacturing firm, has lately introduced an settlement with Adam Mickiewicz College in Poznań for using a brand new Fused Deposition Modelling (FDM) 3D printing approach. The college has developed a way referred to as Liquid for Fused Deposition Modelling (LFDM), which permits for the direct introduction of varied chemical compounds and substances throughout the printing course of.

The LFDM approach opens up a world of prospects by enabling the direct printing of chemical compounds, dyes, radioactive substances, pesticides, antibiotics, nanoparticles, and extra from a polymer materials with a regular FDM printer. Beforehand, many of those substances couldn’t be utilized as a result of bodily or chemical transformations throughout processing. This new approach eliminates the necessity for pricey and energy-consuming processing tools, making it accessible to customers with out specialised gadgets.

Below the settlement, Sygnis has been granted a license to make use of the LFDM approach for manufacturing, advertising and marketing, and distribution of merchandise ensuing from its implementation. The license is legitimate till June 27, 2033, in Poland, and Sygnis pays royalties based mostly on the income generated from the sale of merchandise using this invention.

“It was a novel and easy idea of methods to immediately mix chemistry with 3D printing,” stated Professor Robert E. Przekop from Adam Mickiewicz College in Poznań.

“The strategy was developed in our group three years in the past. After getting ready the patent software, we have now printed our answer and encourage you to make use of the LFDM technique and its additional inventive improvement.”

By acquiring this license, Sygnis goals to extend its income from gross sales of 3D printing equipment and peripherals. The corporate additionally believes that profitable cooperation with the college in commercializing this invention will foster additional collaborations with scientific establishments, driving future improvement.

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t neglect to enroll in our weekly additive manufacturing e-newsletter to get all the most recent tales delivered proper to your inbox.