The area of Additively Manufactured Electronics (AME) is continually rising, and provides customers of the expertise the advantages of fast prototyping of not solely circuit boards, however quite a lot of more and more advanced digital elements as effectively. Because the expertise evolves (and printing decision will increase), AME techniques are quickly trying like an all-singing/all-dancing resolution to an array of electronics manufacturing issues.

On this article, we chat with Andreas Müller, CEO of Germany-based firm J.A.M.E.S GmbH who has a singular enterprise mannequin aimed toward advancing the event of the expertise, and rising the dimensions of the group curious about using 3D printing within the manufacturing of digital techniques and elements.

J.A.M.E.S Overview

J.A.M.E.S (Jetted Additively Manufactured Electronics Sources) is a community-driven platform focussed on harnessing community-driven innovation to advance the event of 3D printed electronics.

Based in 2021 and headquartered in Taufkirchen, Germany, the corporate not solely provides a group platform, but additionally provides in-house electronics printing, a companion community, and consultations on the feasibility of AME initiatives.

“Our purpose is to convey this superior expertise to the following technical readiness degree and reshape the electronics trade by leveraging our deep data of 3D printing expertise,” mentioned Müller.

“We’re dedicated to make AME accessible, usable, and environment friendly for everybody. Extra importantly, we wish to grow to be the go-to useful resource in AME, fostering technical proficiency and design innovation. Entrepreneurs, skilled engineers, and trade pioneers come collectively in our on-line group to develop their data and harness the complete potential of AME.”

Group of AME

The J.A.M.E.S platform is not only a group the place individuals can share concepts, but additionally contains a companion community, the place AM firms concerned in electronics can promote their providers to the group and past.

“The companions of J.A.M.E.S have a significant function on our platform,” defined Müller.

“They contribute to the platform by showcasing their merchandise and expertise, which supplies them with higher visibility and publicity amongst consultants within the AME trade. Our new platform is designed to convey all our companions collectively in a single place, permitting them to spotlight their strengths and promote themselves successfully.”

The companion community options firms in many various verticals, and provides a smorgasbord of printing varieties for a big number of AME use instances.

“We offer a platform the place the SMEs group can discover totally different examples of the appliance, design, additionally join with consultants, and discover the best course of and supplies for his or her wants.”

So whether or not you want some circuit boards printed, otherwise you want some floor remedy applied sciences, then head on over to the trade companion web page to see if you will discover an answer on your engineering challenges.

Rising Complexity

When you have been to take a look at the state-of-the-art of additively manufactured electronics a decade in the past, you’ll see principally examples of 3D printed circuit board traces (at low resolutions), and only a few printed elements.

And for those who have been available in the market for a 3D printer able to printing electronics, your choices would have been restricted. However over the previous few years, with will increase in decision, and an ever-growing library of supplies, the variety of high-fidelity printer choices has elevated considerably. And with the will increase in machine capabilities, the complexity of 3D printed digital elements has equally grown.

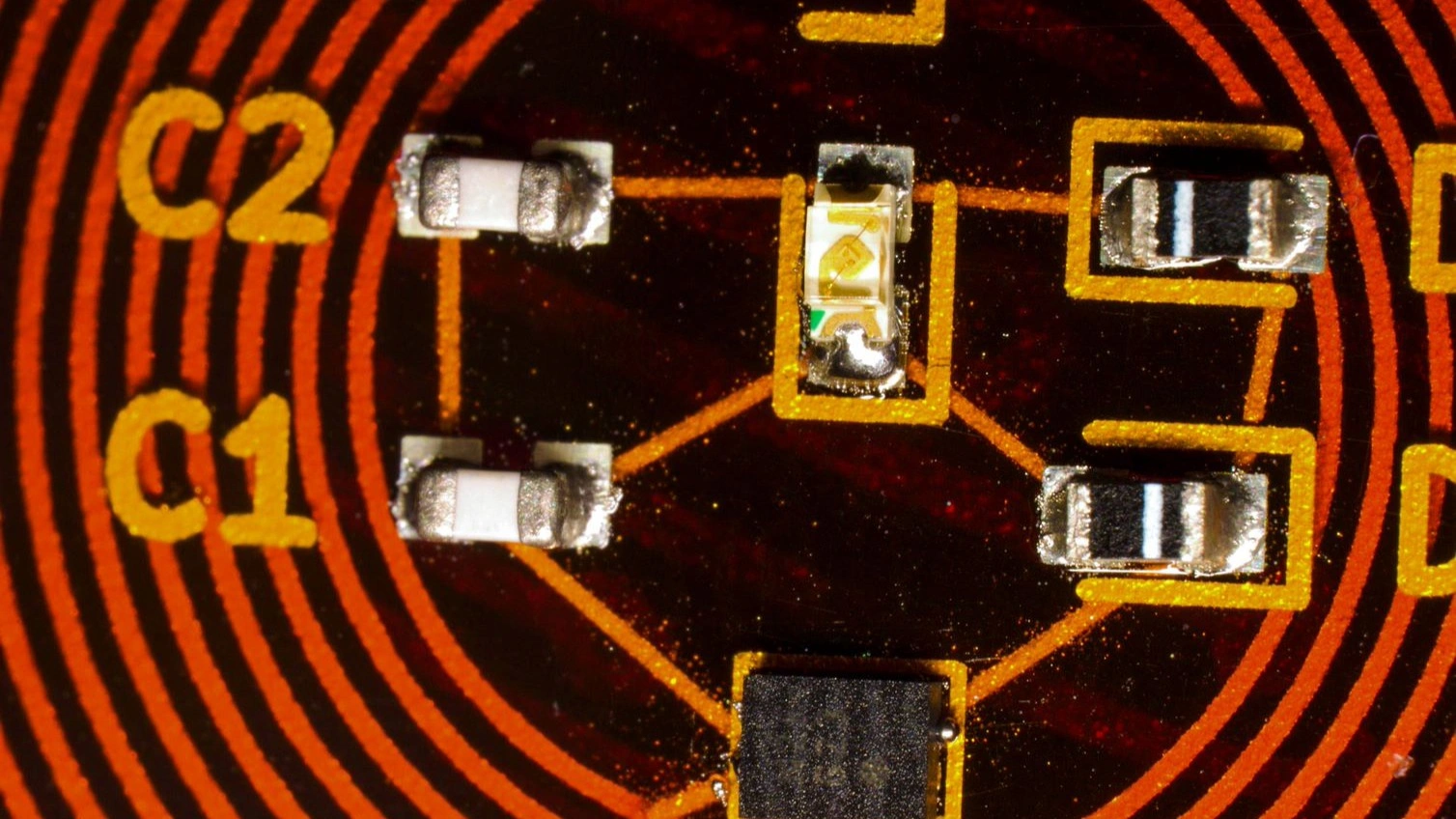

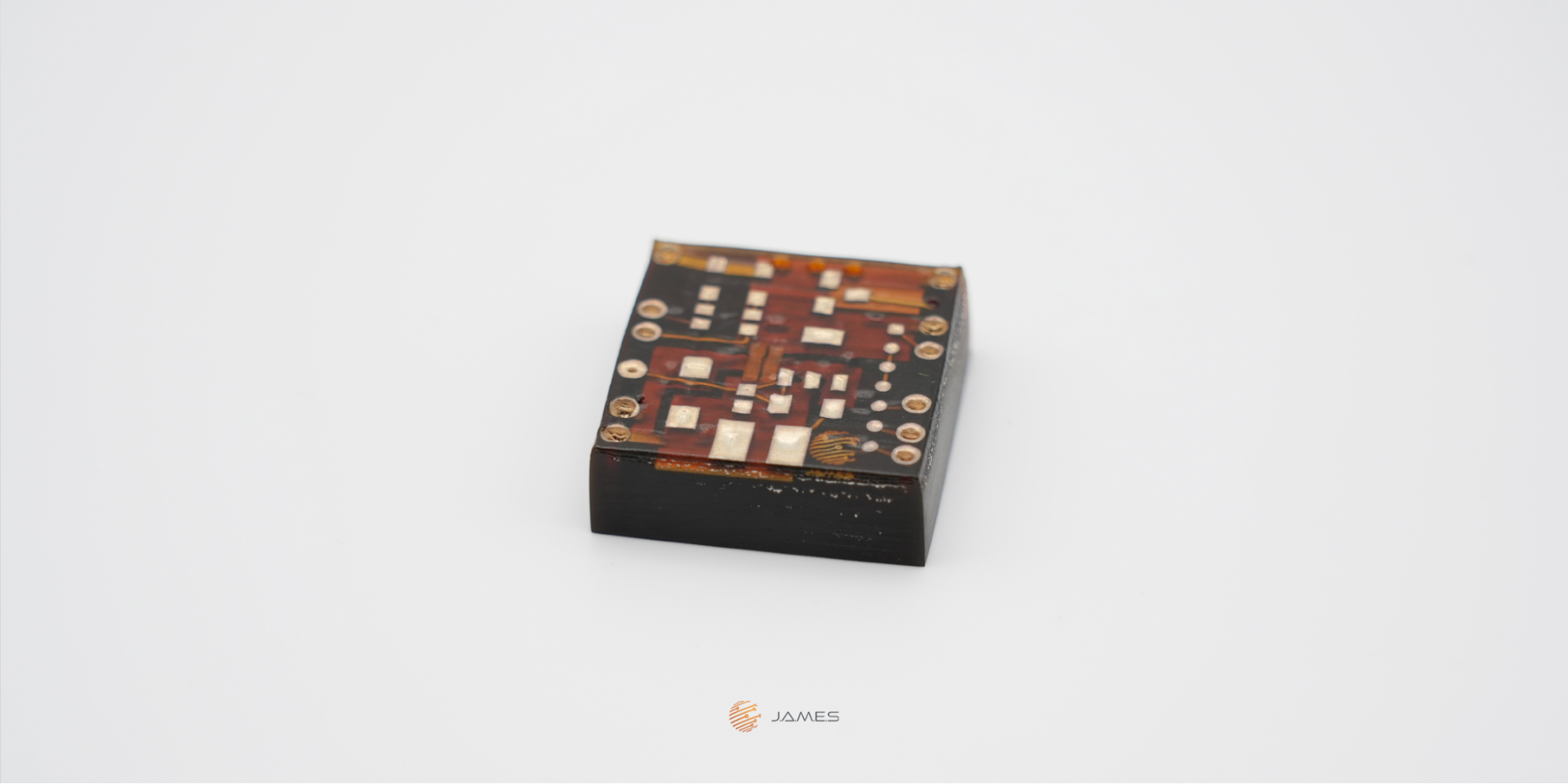

“Essentially the most advanced digital element that we’ve been printed and shared on our platform is the RF synthesizer,” defined Müller.

“This element serves as an distinctive device for testing, demonstrating, and verifying totally different approaches and concepts in extremely built-in electrified volumes of arbitrary form. The RF synthesizer is designed to transmit a constant and stabilized sign on a predefined frequency whereas additionally offering the power to distribute or amplify that sign.”

The RF synthesizer is an instance of a tool that was printed in-house as J.A.M.E.S additionally has the amenities for digital printing on-site.

“We do have our personal in-house lab for digital printing,” confirmed Müller.

“We’re at the moment engaged in some thrilling inside and exterior initiatives, utilizing the DragonFly IV System from Nano Dimension. Our group is very expert and well-versed in using this expertise all through your entire course of, from the preliminary phases to the ultimate manufacturing of printed electronics.

Outreach Actions

Being community-focused, J.A.M.E.S additionally attend occasions to unfold the phrase of 3D printed electronics. The following occasion might be a webinar centered on designing electronics with CST Studio Suite on twentieth July. The corporate may even be giving a chat on the “Electronics Goes 3D” convention in Nuremberg on twenty fifth July.

To maintain updated with upcoming occasions, you possibly can go to the occasions web page at this hyperlink.

And if you wish to study extra concerning the firm on the whole, grow to be a companion, or e book a session on your AME-based initiatives, then you possibly can head on over to the principle web site, proper right here.

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t neglect to join our weekly additive manufacturing publication to get all the most recent tales delivered proper to your inbox.