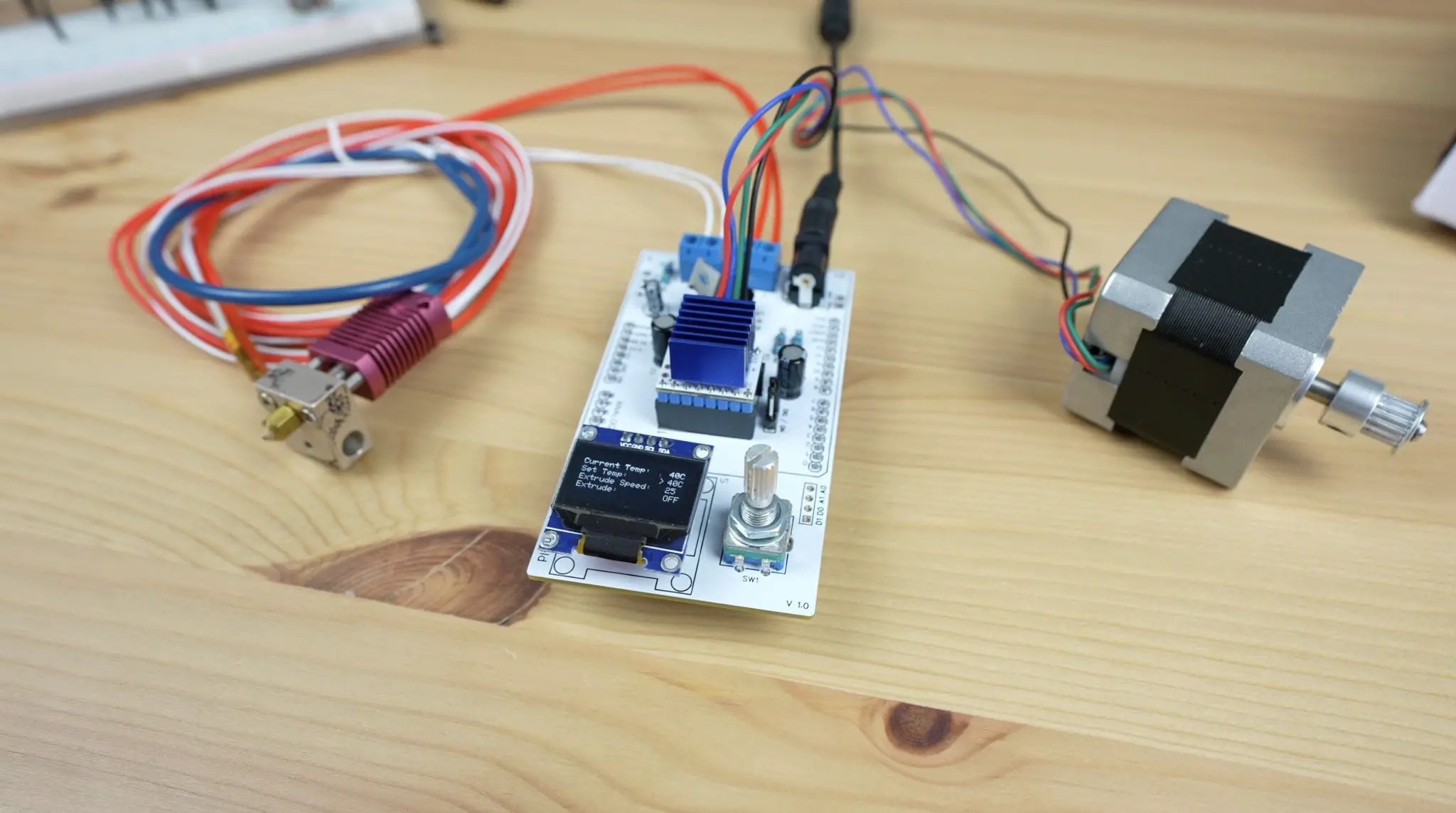

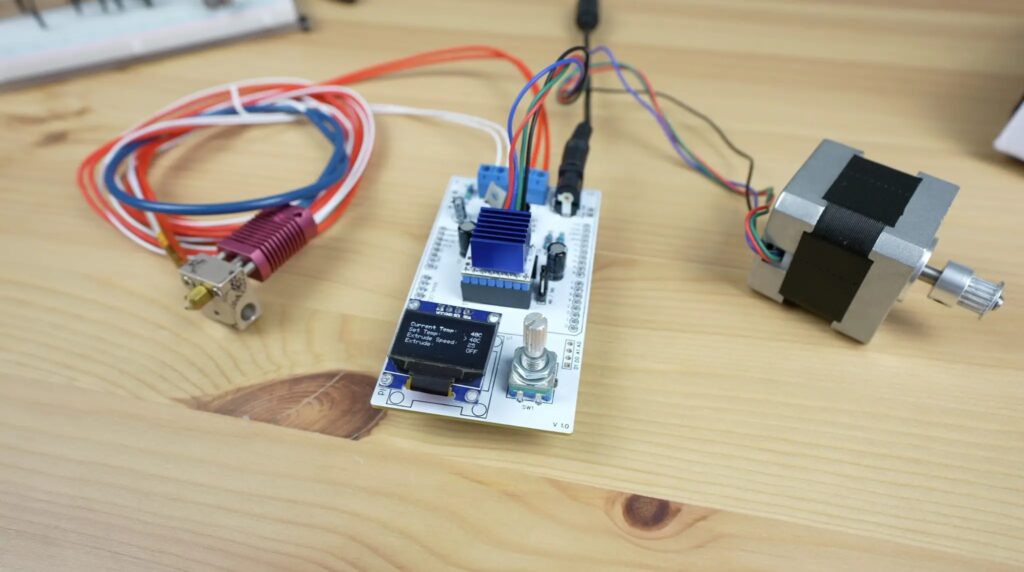

Constructing a devoted 3D printer sizzling finish controller with the Arduino UNO R4 WiFi

— July twenty fifth, 2023

3D printers have to set their sizzling ends to a really particular temperatures suited to the filament materials and preserve them at these temperatures all through the printing course of. Most use PID (proportional-integral-derivative) management for that function, which modulates energy in response to an algorithm that prioritizes stability and prevents suggestions oscillations. However what if you wish to management a sizzling finish that isn’t related to a 3D printer? In that case, Michael Klements has a information on methods to construct a devoted sizzling finish controller.

This devoted sizzling finish controller is beneficial when you’re creating one thing like a filament extruder. Klements designed it for his PET bottle recycler, which turns rubbish into helpful filament. That machine must soften down the plastic and, naturally, it makes use of a sizzling finish to take action. However as a result of it isn’t related to a 3D printer, Klements wanted some strategy to management the temperature of the new finish. A full 3D printer controller board would have been overkill, so he made this devoted controller for the job.

As a result of Klements designed this for the PET bottle recycler, it features a stepper motor driver as effectively. It’s meant to be used with a Creality Ender 3 sizzling finish, however ought to work with others which have customary thermistor suggestions (which is essential for PID management). The customized protect hosts an Arduino UNO R4 WiFi, which is model new and has numerous nice options like a built-in LED matrix. That PCB additionally comprises a MOSFET to manage energy to the new finish, a small OLED display screen, and a rotary push button for navigating the menu.

After assembling the PCB and flashing the offered sketch, you’ll be capable of immediately management a sizzling finish or a whole filament extruder like a PET bottle recycler.

You possibly can comply with any responses to this entry by means of the RSS 2.0 feed.

You possibly can go away a response, or trackback from your individual website.