A analysis workforce at Oak Ridge Nationwide Laboratory (ORNL) has just lately earned recognition on the Annual Advantage Overview for his or her work in creating a light-weight aluminum alloy. This alloy, named DuAlumin-3D, was created in response to the necessity for sturdy and light-weight supplies appropriate for additive manufacturing or 3D printing.

Standard wrought aluminum alloys have posed challenges for additive manufacturing as a result of their troublesome processing. Nonetheless, DuAlumin-3D overcomes these hurdles with its distinctive fatigue energy and creep resistance, outperforming all recognized aluminum alloys at temperatures above 300°C. This printable materials is designed to be used in laser powder mattress additive manufacturing and maintains over half of its energy at temperatures starting from 300 to 315°C.

The alloy will get its title from its twin strengthening mechanisms, enabled by the speedy solidification traits of 3D laser printing mixed with a short warmth therapy. In just below three years, the expertise has advanced from idea to a viable materials for additively manufactured prototypes and merchandise.

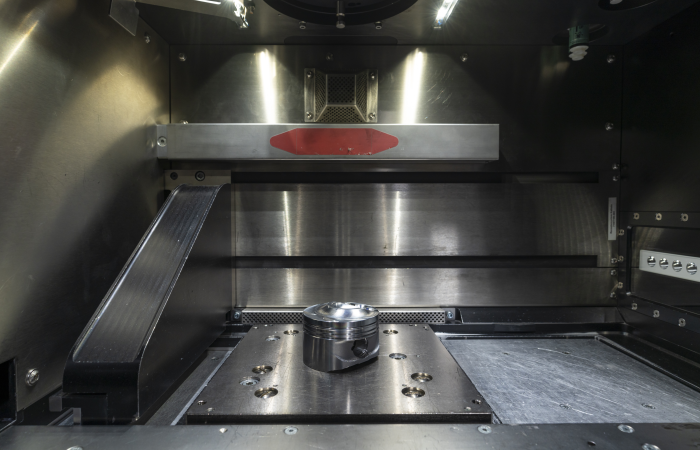

Collaboration performed a vital function within the mission’s success, drawing on the various skillset of ORNL’s workforce and companions like Common Motors and Honda Efficiency Improvement. The alloy has already been used to print pistons efficiently examined in a four-cylinder engine at ORNL. It’s being additional developed for particular car parts, with GM planning to check the alloy’s pistons in a brand new light-weight, high-efficiency V8 medium-duty truck engine.

DuAlumin-3D’s functions prolong to the aerospace sector, the place it may exchange titanium elements to considerably scale back an plane’s weight and improve power effectivity.

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t overlook to join our weekly additive manufacturing e-newsletter to get all the newest tales delivered proper to your inbox.