Trendy electronics have advanced to an important extent immediately, encompassing pc science on one hand and data know-how on the opposite. There’s hardly any digital undertaking these days that doesn’t contain the usage of a microcontroller unit (MCU) or pc programming languages.

Nevertheless, there are nonetheless tasks that may obtain the identical targets as these requiring MCUs and software program, however with easier and extra environment friendly designs.

In our day by day lives, temperature controllers discover quite a few purposes, equivalent to in rice cookers, fridges, water geysers, microwave ovens, and air-conditioners.

One machine that stands out for its skill to operate as a splendid temperature controller, when paired with an MCU and appropriate programming, is the TMP36.

By exactly measuring temperatures and offering enter to the MCU, which then converts the sign into management instructions for related units like relays, the TMP36 simplifies temperature management.

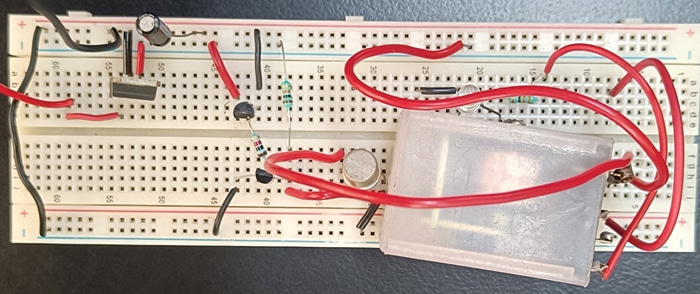

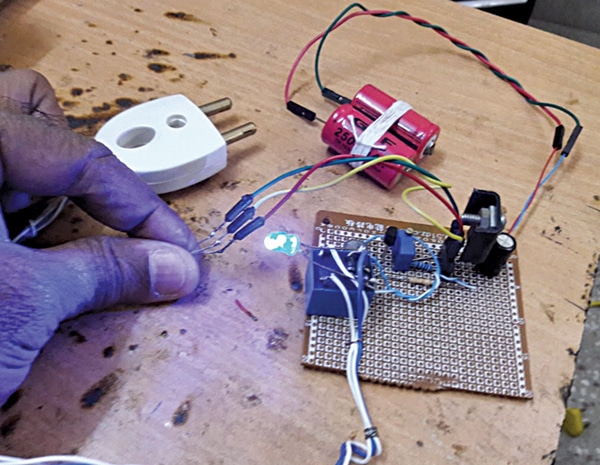

On this undertaking, the TMP36 controls a relay instantly, with out the necessity for an MCU or software program. The circuit, composed of some discrete parts, is each exact and simple. Fig. 1 reveals the prototype examined within the EFY lab.

Temperature Controller – Circuit and Working

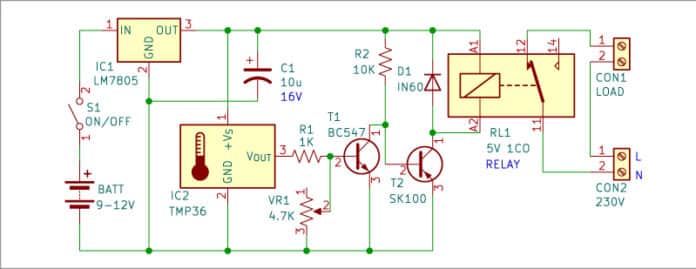

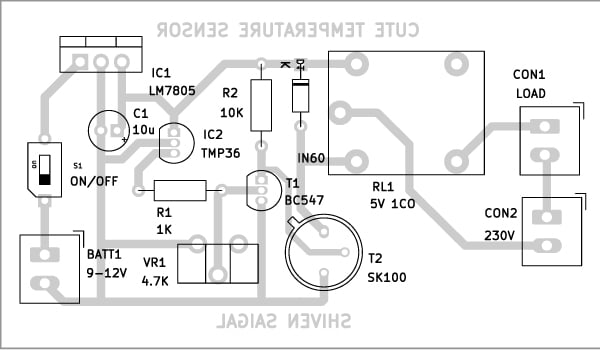

The circuit diagram of the lovable temperature sensor is proven in Fig. 2. The sensor is constructed round a 5V voltage regulator LM7805 (IC1), the TMP36 sensor (IC2), a 5V one-changeover relay (RL1), npn transistor BC547 (T1), PNP transistor SK100 (T2), diode 1N60 (D1), and some different parts.

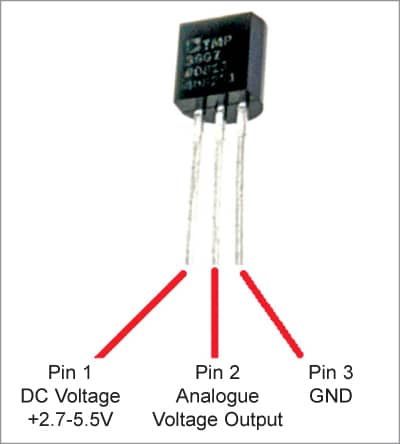

The core of the circuit is the TMP36 temperature sensor. It possesses the next traits: low voltage operation (2.7V to five.5V), an working temperature vary of -40°C to +150°C, linear operation (y=mx+c), temperature measurement instantly in millivolts, uniform linearity of 20mV/°C, and a quiescent present of lower than 50µA.

It additionally encompasses a ramp-up of three°C/second and a ramp-down of 6°C/second. Pin configurations of TMP36 are proven in Fig. 3.

The undertaking’s working precept is straightforward. The TMP36 sensor detects the temperature and converts it into millivolts, that are then measured. When the TMP36 senses warmth, the bottom voltage of transistor T1 exceeds the bias restrict.

In consequence, each transistors T1 and T2 conduct, energizing the 5V relay, which allows the load related throughout its contacts. The NPN-PNP junction (the Sziklai pair) presents a bonus over different Darlington pairs because of its decrease base-emitter voltage of 0.61V, in comparison with 1.22V for different Darlington pairs, making low-voltage operation doable.

Calibration

That is the place we get rid of the necessity for cumbersome MCUs and simplify the circuit. The 4.7k pot (VR1) is a exact multi-turn kind used to set the temperature setpoint. Warmth the probe to the specified temperature after which alter pot VR1 in order that the relay simply de-energizes. Past this level, if the temperature will increase, the relay will energize once more.

The usually closed (NC) or usually open (NO) contact of the relay can be utilized to disconnect/reconnect a charger, gadget, cooker, soldering iron, and so forth. Conversely, when the temperature decreases, the TMP36 cools down, de-energizing the relay and reconnecting the machine.

For the reason that TMP36 has a ramp-up of three°C/second and a ramp-down of 6°C/second, it mechanically accounts for a 3-degree overlap per second to keep away from oscillation over a imply temperature. Moreover, bodily our bodies don’t dissipate warmth rapidly, except quick cooling is offered.

| Temperature Controller Sensor Elements Listing | |

| Semiconductors: | |

| IC1 | – 7805, 5V regulator |

| IC2 | – TMP36 temparature sensor |

| D1 | – 1N60 diode |

| T1 | – BC547 npn transistor |

| T2 | – SK100 PNP transistor |

| Resistors (all 1/4-watt, ±5% carbon): | |

| R1 | – 1-kilo-ohm |

| R2 | – 10-kilo-ohm |

| VR1 | – 4.7-kilo-ohm pot |

| Capacitor: | |

| C1 | – 10µF, 16V electrolyte |

| Miscellaneous: | |

| CON1, CON2 | – 2-pin connector |

| RL1 | – 5V, 1C/O relay |

| S1 | – On/off change |

| Batt.1 | – 9-12V battery |

Building and Testing

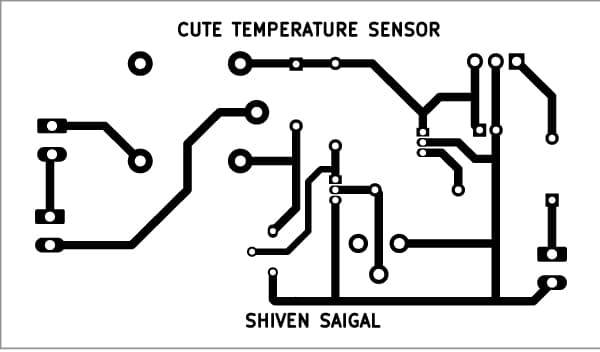

The actual-size, single-side PCB format for the lovable temperature sensor is proven in Fig. 4, whereas its element format is proven in Fig. 5. After assembling the circuit on PCB, enclose it in an acceptable field.

Alternatively, you may assemble the circuit on a general-purpose PCB, as proven within the writer’s prototype depicted in Fig. 6. Place all of the parts and the PCB in an acceptable enclosure, and supply terminal strips for the 230V provide enter and output individually.

This temperature Controller has numerous purposes:

Charging Ni-Mh or Li-ion batteries: It may be used to cost Ni-Mh or lithium-ion (Li-ion) batteries. By stopping overcharging when the battery reaches a particular temperature (45°C to 50°C for Ni-Mh batteries and 45°C for Li-ion and Lipo batteries), the undertaking extends the batteries’ lifespan past regular utilization.

Soldering iron tip temperature management: Use the NC connection to disconnect the soldering iron provide and place the TMP36 barely away from the tip, the place the temperature stays beneath 150°C.

Modulating the fuel burner when water begins boiling: Use the usually open (NO) connection to manage the shimmer knob/motor and place the TMP36 in direct contact with the boiling liquid, utilizing a leak-proof metallic defend for the TMP36.

In a world pushed by superior know-how, this temperature sensor reminds us that simplicity will be highly effective. Streamlining temperature management with precision and ease opens doorways to countless prospects for enhancing our day by day lives.

Obtain PCB and Element Format PDFs: click on right here

You too can verify the TMP36 Datasheet.

Somnath Bera is an electronics and IoT fanatic working as Normal Supervisor at NTPC