E3D has introduced it’s discontinuing its ToolChanger and Movement system, which received the TCT Polymer {Hardware} Award again in 2018.

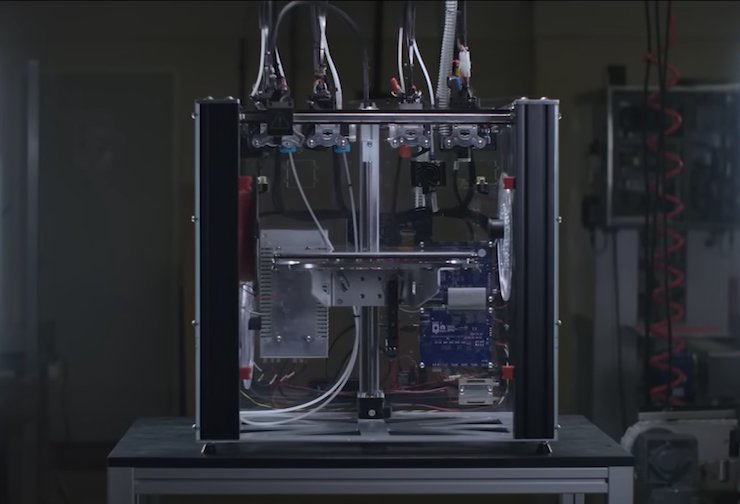

The ToolChanger product was a sophisticated analysis platform that will enable customers to make use of as much as 4 multi-material or multi-functional instruments throughout a single print.

E3D launched the platform greater than 5 years in the past, with the goal to encourage the adoption of machines with a number of toolheads. Hundreds of E3D Toolchangers are mentioned to have been deployed, with state-of-the-art analysis and growth services, universities, and main tech corporations among the many customers, whereas Prusa has additionally since developed the Prusa XL 5-tool system.

“All through its lifespan, we now have been amazed by the unimaginable methods during which our clients have utilised the machine,” an E3D weblog learn. “The fervour and creativity demonstrated by the 3DP neighborhood in creating their very own instruments and pushing the boundaries of analysis and growth have been actually inspiring. It was their revolutionary spirit that motivated us to take what was initially a ‘weekend ardour challenge’ (as dubbed by late E3D co-founder Sanjay Mortimer) and switch it right into a commercially viable machine.”

The corporate has mentioned that because it continues to evolve, it has made the ‘troublesome resolution’ to discontinue the product, suggesting it’s going to place a larger concentrate on its ‘core experience in FDM extrusion methods’. E3D believes this ‘strategic realignment’ will allow the corporate to higher serve its clients with its main product choices, however does state ‘we’re additionally actually happy to say you’ll be seeing much more toolchanging 3D printers sooner or later – in fact, they’re hush-hush for now.’

E3D has sought to substantiate that its ToolChanger merchandise will stay open supply, with all information associated to the system set to stay out there to permit ‘everybody to leverage its design and construct upon its basis.’ Spare components can even proceed to be provided for the ToolChanger and Movement system till inventory runs out, and can promote clean software plates, guaranteeing customers can keep and restore their machines, for the foreseeable future. Moreover, the corporate says it’s going to proceed to work with 3D printer producers working to develop their very own methods.