AM Discussion board Berlin 2023 had the overarching theme of Additive Manufacturing in a VUCA world. What’s a VUCA world, you may ask? It’s one characterised by volatility, uncertainty, complexity, and ambiguity.

A variety of audio system tackled the query of how industrial 3D printing can present a aggressive edge, from cutting-edge AM techniques suppliers to an organization with over 170 years of producing expertise.

Partnerships are on the core of this method, and AM Discussion board Berlin 2023 illustrated this level by inviting 3D printing leaders to share the stage with enterprises placing additive manufacturing to work. SLM Options CEO Sam O’Leary encapsulated the method, stating, “If you happen to don’t accomplice otherwise you don’t allow integration, what you’re left with is a extremely cool, remoted piece of know-how.”

This text, from our collection of insights from AM Discussion board Berlin 2023, seems at a number of such ventures and the way additive manufacturing can be utilized with extra conventional strategies.

SLM Options and additive manufacturing at Bosch

Amidst the rising tide of technological development, adopting 3D printing as a key aggressive benefit within the {industry} is not a novelty however a necessity. This premise was underlined when AM Discussion board Berlin 2023 moderator Sven Krause of SK Consulting invited two {industry} veterans to debate their collaborative efforts in driving this alteration. The duo comprised Dr. Kai Kuhlmann, Director of Technical Director Technical Capabilities, Powertrain Options, Robert Bosch, and Sam O’Leary, CEO of SLM Options.

Bosch’s foray into additive manufacturing ought to hardly be a shock. But, their productive alliance with SLM Options, a famend developer and enabler of know-how, has rendered probably the most profound affect.

Opening the dialog, O’Leary declared that the mission of SLM Options was to “change the way forward for manufacturing ceaselessly.” Greater than mere rhetoric, he argued that this transformation is possible solely by way of “deep-rooted partnerships, partnerships that foster innovation, take away boundaries, and fairly merely partnerships that simply ship.”

SLM’s process is to empower industrial change. “Our goal is to ship what is required to allow this industrial transformation,” defined O’Leary. This interprets as fixed pursuit of price discount, uncompromised high quality, and superior efficiency.

Nonetheless, O’Leary cautioned that the best know-how and exemplary use circumstances are merely part of the equation. The important thing catalyst, he proposed, lies in a deeper shift: strong alliances facilitating a symbiotic future.

Fittingly, SLM’s partnership with Bosch is a testomony to this built-in method. The alliance emphasizes integrating SLM’s know-how into present, well-established manufacturing processes, aligning with their objective of complete industrial manufacturing. The collaboration additionally signifies a rising industry-wide recognition that additive manufacturing isn’t merely fascinating however an important resolution to international manufacturing challenges.

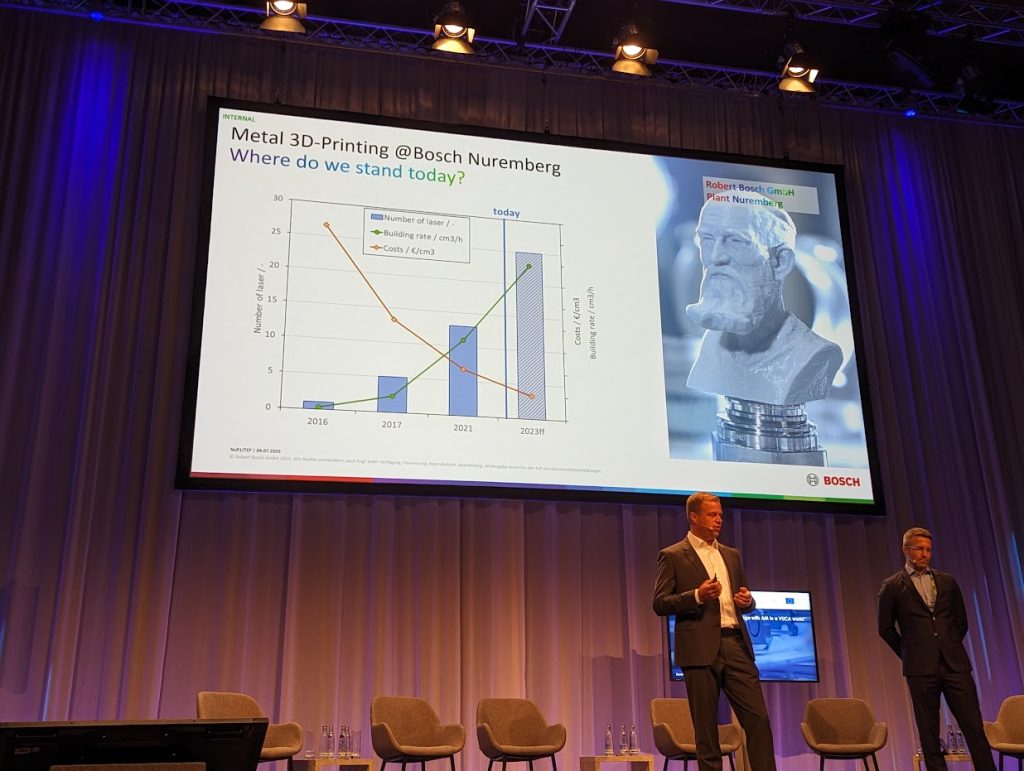

Within the sprawling ecosystem of Bosch, with over 400,000 associates worldwide, the Powertrain Options division types a strong a part of the mobility options enterprise sector. Nuremberg is a hub for additive manufacturing at Bosch, and Dr. Kuhlmann painted an image of a rising and environment friendly operation. Over the past decade, this website has develop into dwelling to 5 steel 3D printing machines. The Nuremberg website, he claims, is not any mere printing facility. It oversees the whole course of chain, from 3D printing to machining and milling, together with warmth remedy.

Dealing with inside purposes throughout Bosch, the division completes over 300 initiatives yearly, producing greater than 2000 components, some in small collection of greater than 200. As Dr. Kuhlmann emphasised, the trajectory is certainly one of fixed progress and productiveness improve, balanced by price discount.

Nonetheless, Bosch’s success will not be with out its challenges. A key problem could possibly be characterised as a catch-22 scenario – the necessity for brand new machines to generate enterprise versus the requirement for companies to spend money on new machines. This standoff wants a breakthrough, a unique method to make the most of additive manufacturing, not as a substitute however as a decisive benefit, to enhance product efficiency and management prices.

For Bosch, the shift from technology-driven to product-focused is a big leap. The highlight is not merely on the quick, versatile nature of AM know-how however on the benefits this will supply to the merchandise. The brand new mindset has proven promising outcomes, particularly with the significance of high quality within the automotive {industry}. Bosch can not afford to check every with the quantity of components produced. This predicament has emphasised dependable and reproducible processes and the necessity to perceive whether or not an element is nice or unhealthy on the finish of manufacturing.

To make sure high quality, the Nuremberg staff has been sharing some great benefits of the know-how inside Bosch, build up know-how, and sharing success tales. As Dr. Kuhlmann identified, fulfilling automotive expectations regarding high quality and value management requires extra than simply producing the proper merchandise. It additionally necessitates an understanding of shopfloor group and the growing position of automation.

Bosch’s journey began small, however it’s set to get large. Dr. Kuhlmann’s present estimation means that older-generation machines will proceed to drive pseudo-production – an interim stage between prototyping and mass manufacturing. Nonetheless, Bosch should transition to extremely productive, cost-effective machines, such because the next-gen SLM choices, to succeed in the final stage- serial manufacturing.

Dr. Kuhlmann harassed the significance of strategic partnerships on this endeavor, hinting at a deep alliance with SLM Options. Such collaborations, he implied, will present the important thing to unlock the subsequent stage of Bosch’s AM journey, to extend productiveness, management processes, and meet each inside and buyer expectations.

Regardless of the challenges, Dr. Kuhlmann is assured that additive manufacturing will likely be a sport changer for Bosch. Anticipating rising quantity, aggressive costs, and dependable processes makes him constructive concerning the future. Leveraging AM design, he argues, will present a decisive aggressive benefit in product efficiency and unit price.

“Product efficiency is vital to crossing the chasm,” Dr. Kuhlmann stated, indicating a watershed second within the firm’s additive manufacturing journey and referencing an idea launched by Geoffrey Moore, representing the leap from early adoption to the mass market.

Lowering manufacturing prices with 3D printing: insights from {the electrical} connector {industry}

Lowering manufacturing prices whereas sustaining product integrity is an more and more urgent problem inside the 3D printing {industry}. “Innovation is about extra than simply the manufacturing course of; it additionally encompasses the problem of adhering to established {industry} requirements and certifications,” famous Dr. Simon Althoff, Head of the Good Connectivity Competence Heart at Weidmüller Interface, throughout an AM Discussion board 2023 keynote handle on decreasing manufacturing prices within the electrical connector {industry}.

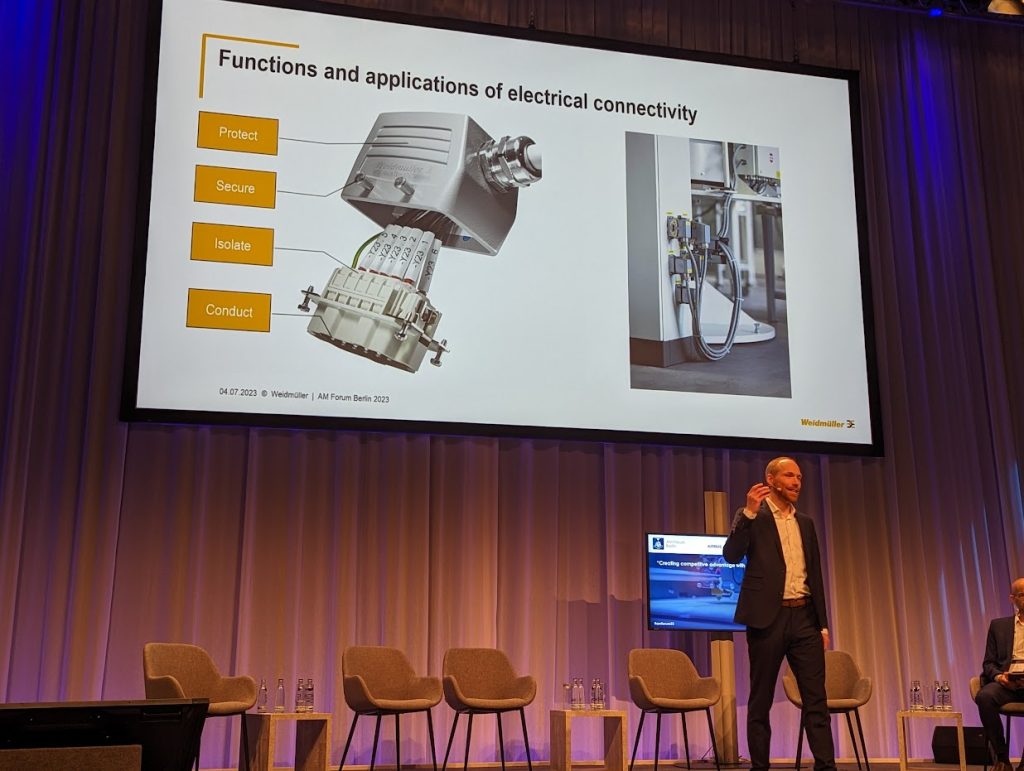

For context, electrical connectors — primarily, units that transmit electrical energy from a supply to a tool — are used extensively in varied sectors. Their manufacturing is a billion-euro {industry}, with just a few different corporations producing comparable electrical connectors and cupboard merchandise. The connectors serve 4 core features: defending, securing, isolating, and conducting electrical energy. They should be resilient towards parts corresponding to water and mud, strong sufficient to stay in place and have the proper insulation for security and performance.

Throughout his presentation, Dr. Althoff underscored the twin position of {the electrical} connector {industry}: not simply promoting a product but additionally “the respect of the certificates.” Trade norms, standardizations, and certifications play a vital position, however they will additionally create pressure with the agility of 3D printing. “It’s a belief problem,” Dr. Althoff noticed. “Additive manufacturing is a correct and useful manufacturing know-how, however our prospects are usually not simply shopping for a product. They’re shopping for the product with the certificates.”

Regardless of its advantages, additive manufacturing, as Dr. Althoff identified, struggles to navigate an intricate panorama of certifications and {industry} requirements. The intensive certification checks symbolize a big price. Flammability checks, as an example, are important to make sure that parts don’t flip cupboards into proverbial fireplaces. For this, AM has offered options in flame-retardant plastic components.

How you can scale 3D printing?

Within the adoption of commercial 3D printing, there’s a nuanced steadiness to be struck between know-how and custom. Additive manufacturing presents a transformative method to producing objects corresponding to electrical connectors, together with low-run merchandise that may historically be uneconomical as a result of intensive guide labor concerned.

“We have now automated injection molding machines that are producing 24/7,” Dr. Althoff defined, “we even have lower-run merchandise. For 300-400 connectors, we can not make [with injection molding], however the buyer expects it. Subsequently, we want to additive manufacturing as an answer for our low-run merchandise.”

3D printing might alleviate the ache factors of producing area of interest parts, reducing time and prices whereas delivering the requisite high quality and requirements for industrial-grade merchandise.

Nonetheless, the transition to additive manufacturing isn’t totally with out obstacles. Based on Dr. Althoff, the {industry}’s explicit problem lies in post-processing. “We have now the know-how and machines out there; now we have severe manufacturing additionally out there,” he acknowledged. “However ultimately, we lack industrial post-processing.”

After which there’s the matter of certification. Merchandise manufactured this fashion should meet strict requirements and laws, the ‘golden’ benchmark being a UL certificates. And herein lies the crux of the difficulty. As Dr. Althoff put it, “It’s a belief problem.”

Enter Dr. Starnecker, CEO of Weisser Spulenkörper, an injection molding firm eagerly exploring the probabilities of additive manufacturing. They’ll produce at decrease prices than plastic injection molding for volumes of lower than 10,000 items and fewer than one cubic centimeter.

As Dr. Starnecker emphasised, this flexibility is “the fourth dimension within the manufacturing.” That encompasses freedom of design, the flexibility to iterate extra rapidly through the growth section, and variability within the amount of produced components.

Notably, Weisser Spulenkörper is already producing high-quality purposeful components utilizing additive manufacturing. The main focus is on “at the least pretty much as good as the standard mannequin,” however there’s an ambition for extra, a big step towards “industrial additive manufacturing.”

A shift in injection molding

Dr. Starnecker explains {that a} shift within the injection molding {industry}’s norms is underway. Prices starting from €50,000 to €300,000 pose vital boundaries for producers, particularly when the market reception for a brand new product is unsure. The elemental disruption – the flexibility to provide, check, and introduce new merchandise to the market with restricted monetary danger – exemplifies the promise of additive manufacturing. “[Customers] don’t even know if the market will decide it up. They’ve an concept that it’d decide up, and so they say okay, we produce it additively… and the second the market picks it up, we’re pleased as a result of we are able to produce extra components,” Dr. Starnecker elaborates.

Dr. Starnecker identifies a distinct segment the place additive manufacturing might excel, not producing tens of millions of an identical objects, however in “these 600 merchandise the place you solely have a amount lower than 10,000 components per 12 months.” This candy spot, the place customization and low quantity can coexist economically, might additionally considerably cut back storage prices and capital tied up in molds.

Moreover, the know-how’s promise extends past easy price financial savings. Every of the “10,000 components” could possibly be a novel merchandise, providing unparalleled product customization and complexity.

Dr. Starnecker emphasizes that constructing belief in additive manufacturing and establishing it as a dependable, repeatable industrial course of is crucial. If such belief could be fostered, he believes additive manufacturing can reply sustainability and financial challenges. “We want extra belief in the neighborhood and the {industry},” earlier than concluding with a rallying name to “go away the playground and get severe!”

AM Discussion board returns to Berlin in 2024. Extra data is obtainable right here.

What does the way forward for 3D printing for the subsequent ten years maintain?

What engineering challenges will must be tackled within the additive manufacturing sector within the coming decade?

To remain updated with the newest 3D printing information, don’t overlook to subscribe to the 3D Printing Trade e-newsletter, observe us on Twitter, or like our web page on Fb.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you on the lookout for a job within the additive manufacturing {industry}? Go to 3D Printing Jobs for a choice of roles within the {industry}.

Featured picture reveals Sam O’Leary, SLM Options, [R] and Dr. Kai Kuhlmann of Robert Bosch. Picture by way of AM Discussion board Berlin.