Israeli electronics 3D printer producer Nano Dimension is buying the know-how and mental property of UK-based 3D design simulation and optimization developer Additive Move.

This acquisition is claimed to mark a major milestone in Nano Dimension’s improvement roadmap. Certainly, computer-aided engineering and design parts are central to the corporate’s design-through-manufacturing product technique.

Additive Move’s core know-how shall be built-in into FLIGHT, Nano Dimensions proprietary design bundle suite.

“The Additive Move group is thrilled to hitch Nano Dimension,” commented Alexander Pluke, Additive Move’s Chief Government Officer and Chief Expertise Officer. “We’re lucky to have discovered a terrific associate in Nano Dimension the place our innovation may be leveraged to its most potential. We look ahead to constructing on our spectacular monitor file and persevering with to develop Additive Move’s software program and improve Nano Dimension’s main AM and AME product choices.”

Nick Geddes, Senior Chief Expertise Officer of Nano Dimension, acknowledged that “The acquisition will add appreciable firepower to the power of our clients to leverage our main digital manufacturing options.”

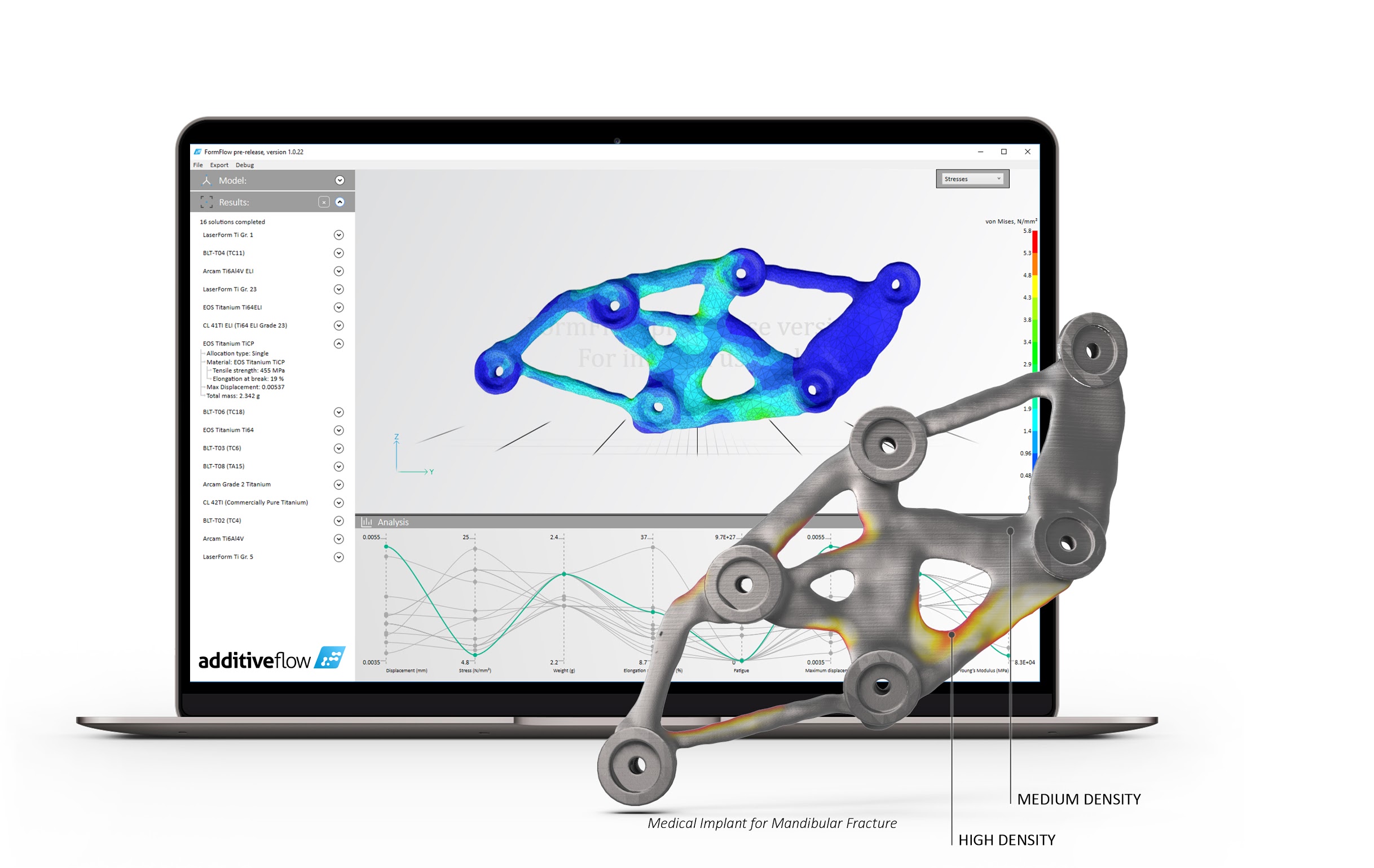

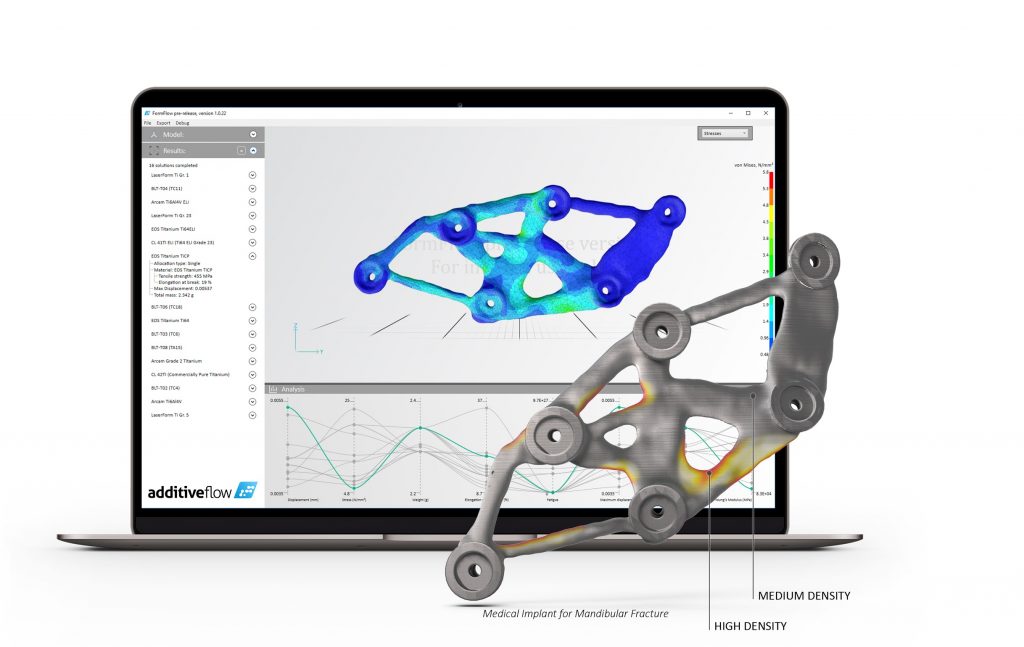

Additive Move’s simulation software program

Since its basis in 2017, Additive Move has developed high-performance and high-quality simulation software program for mechanical, thermal, and thermo mechanical properties.

Additive Move launched its additive manufacturing optimization software program, referred to as FormFlow, again in 2020. This software program providing addresses design, manufacturing, and high quality choices, while optimizing value, weight, manufacturing productiveness, and manufacturing yield. The important thing buyer base of this software program incorporates the superior optics and optoelectronics, aerospace and protection, semiconductors, superior power, and electronics verticals.

A multi-functional program, FormFlow provides the power to use a number of user-defined parameters for simultaneous geometry, course of parameters, and materials optimization. The software program makes use of physics-driven algorithms, synthetic intelligence (AI), and graphics processing unit (GPU) know-how to course of and resolve complicated efficiency points within the design part. Furthermore, FormFlow may be tailor-made to work with a spread of fabric properties, and multi-material designs.

“Our answer was born out of actual engineering challenges we confronted to harness the aptitude of superior manufacturing,” defined Pluke. “Our platform is constructed from the bottom as much as deal with all of the complicated knowledge and choices of digital engineering, so groups can concentrate on their key targets.”

In the end, Nano Dimension claims that the addition of this software program will enable its clients to duplicate, design, and increase additively manufactured electronics parts’ prototypical layouts, in a quick and cost-effective method.

“We’ve been wanting on the software program marketplace for simulation and optimization choices for a while,” added Geddes. “There are various robust options available in the market that do sure parts of these difficult duties, however it’s Additive Move’s product that stood out by way of the performance we would have liked for a holistic answer, particularly within the context of our necessities throughout AME and multi-dimensional polymer, metallic and ceramic AM.”

3D printing software program

Course of optimization and simulation software program is a rising space inside additive manufacturing. Certainly, current hype surrounding synthetic intelligence has seen various corporations incorporating AI into their software program choices. This 12 months’s 3D Printing Business Government Survey highlighted AI as being key to the way forward for 3D printing.

Earlier this month, 3D Printing Business sat down with Daghan Cam and Luke Rogers, CEO and Industrial Director, respectively, at 3D printing software program developer Ai Construct. Since 2015, the London-based firm has labored to develop AI pushed toolpath era and automatic high quality assurance software program for large-format additive manufacturing.

Key to Ai Construct’s mission is leveraging AI and machine studying know-how to simplify the economic additive manufacturing course of, making it extra accessible to extra corporations. “We try to make it tremendous straightforward for anybody. Even a designer that doesn’t have a lot 3D printing background ought to be capable of ship their designs into machines,” defined Cam. As such, it was introduced earlier this 12 months that Ai Construct had developed a course of permitting customers to create superior 3D printing toolpaths utilizing pure language prompts.

Elsewhere, engineering software program developer nTop (beforehand nTopology) not too long ago launched a serious replace to its flagship product: nTop 4. This replace is claimed to permit engineers to beat additive manufacturing bottlenecks, by offering new digital instruments to design and manufacture complicated elements. nTop claims that this new providing offers enhanced design flexibility, decreased time to market, improved half high quality, and value discount.

“At nTop, we’ve at all times believed that design is on the core of fixing the world’s hardest engineering issues. nTop 4 marks the following stage of our journey enabling engineers to ship extremely engineered AM elements for merchandise to succeed in new ranges of efficiency,” commented Bradley Rothenberg, nTop Co-founder, and CEO.

Subscribe to the 3D Printing Business publication to maintain updated with the most recent 3D printing information. You may also comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing business? Go to 3D Printing Jobs to view a number of obtainable roles and kickstart your profession.

Featured picture exhibits Additive Move’s FormFlow software program. Picture through Additive Move.