The lightweighting of parts is essential to introducing new sustainable plane and spacecraft sooner. 3D printed plastic components can supply advantages on this space, decreasing vitality use and growing the vary of recent plane. In November 2022, Stratasys introduced that it utilized simulation know-how from Hexagon’s Manufacturing Intelligence division to seize the behaviour of its ultra-lightweight Antero bolstered polyetherketoneketone (PEKK) and its additive manufacturing processes.

In line with Stratasys, the adoption of AM for structural parts has remained gradual as a result of safety-critical nature of the aerospace business and the laws imposed on components. Within the unique press launch asserting their partnership, Hexagon and Stratasys stated that by offering engineering groups the simulation instruments to validate the supplies that can obtain the required half efficiency, they’re supplying the ‘lacking hyperlink’ which can allow designers to make breakthroughs.

Foster Ferguson, International Director of Aerospace at Stratasys advised TCT: “While you begin to discuss concerning the dimensional accuracy and printing to what the requirements are on the lookout for, hitting these specs is admittedly vital. No matter we’re testing, longevity, UV, warmth, fatigue, no matter, characterising that knowledge and giving it to the engineer is crucial. That’s why the Hexagon Digimat software program is so vital to your complete course of. We wish to in a position to give confidence with the technical proof on the again finish of the print, that the tolerances have been met for the designs for the very distinctive spacecraft.”

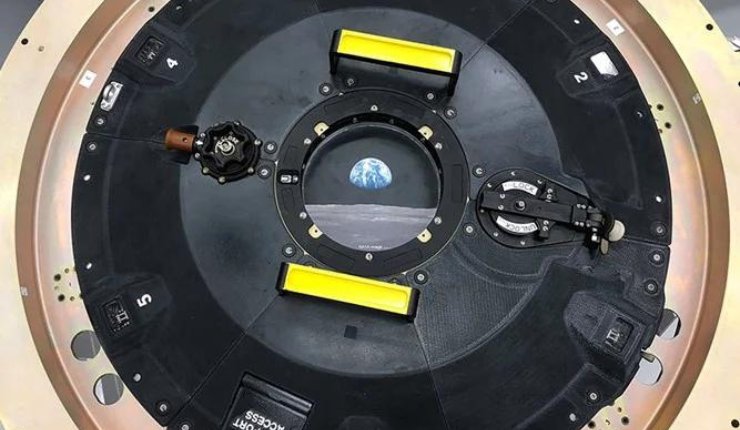

Multi-scale fashions of Stratasys Antero 840CN03 and Antero 800NA have been added to Hexagon’s Digimat supplies change ecosystem, with related print parameters from Stratasys’ aerospace-ready 3D printers. The fashions permit engineers to create digital twins that precisely predict how components printed with the chosen materials and accredited aerospace-ready Stratasys printer will carry out. In line with Hexagon, the components will be digitally simulated with real-world use-cases and certification checks earlier than any bodily prototypes are manufactured. The supplies are already being utilized in aerospace engineering, with Lockheed Martin utilizing Antero 840CN03 to create NASA’s Orion spacecraft docking hatch cowl.

Talking concerning the significance of lightweighted parts, comparable to those designed utilizing the simulation software program, Ferguson stated: “The lightweighting is essential, clearly to engineers who’re at all times on the lookout for methods to save lots of kilos, each pound that you simply save in spaceflight may be very important by way of gasoline prices. Nice points of the supplies are that they’re very fatigue resistant, very sturdy, and it has electrostatic dissipative properties.”

Ferguson advised TCT about the advantages of utilizing simulation software program: “Assembly particular necessities and laws is definitely one of many advantages. There are totally different laws in business journey and area journey. With area journey you’re extra involved about general questions of safety and ensuring that when this factor goes on the market it’s going to satisfy the unique design specs and necessities a buyer is asking for. Prior to now we’ve gone by way of in depth testing on our machines, printing the coupons, testing the filaments and creating an information set that we are able to publish. We use it within the public discussion board in order that engineers can use an information set and create an equivalency of their very own knowledge, based mostly on that foundational knowledge.”

Hexagon says that its Digimat software program offers producers the power to design lighter components that may match metals in efficiency and keep away from expensive ‘overengineering’. The corporate first started working with Stratasys over a decade in the past, and in that point has characterised and added high-performance thermoplastics comparable to ULTEM 9085, ULTEM 9085 CG, ULTEM 1010, and Nylon12CF to the Digimat software program. In line with Ferguson and Stratasys, the power of 3D printed supplies such because the PEKKs to switch functions that will usually be produced from aluminium and metal factors to rising use within the aerospace business.

This story was first featured within the North American and European editions of TCT Journal in early 2023.