Following the worldwide COVID-19 pandemic, the event and fast deployment of mRNA vaccines highlighted the crucial position of lipid nanoparticles (LNPs) within the context of prescribed drugs. Used because the important supply automobiles for fragile RNA-based therapies and vaccines, LNPs shield the RNA from degradation and guarantee efficient supply throughout the physique.

Regardless of their crucial significance, the large-scale manufacturing of those LNPs noticed quite a few bottlenecks in the course of the pandemic, underscoring the necessity for scalable manufacturing methods that might preserve tempo with world demand.

Now, in a paper revealed within the Proceedings of the Nationwide Academy of Sciences, researchers on the College of Pennsylvania describe how the Silicon Scalable Lipid Nanoparticle Technology platform (SCALAR), a reusable silicon- and glass-based platform designed to remodel the manufacturing panorama of LNPs for RNA therapeutics and vaccines, presents a scalable and environment friendly answer to the challenges uncovered in the course of the COVID-19 disaster.

“We’re excited to create a bit of expertise platform that bridges the hole between small-scale discovery and large-scale manufacturing within the realm of RNA lipid nanoparticle vaccines and therapeutics,” says co-author Michael Mitchell, affiliate professor of bioengineering within the College of Engineering and Utilized Science at Penn. “By doing so, we have successfully leapfrogged the clunky, time-consuming, and dear limitations that decelerate the manufacturing ramp-up of promising new RNA medicines and vaccines.”

The intricacies of RNA-based therapies require the RNA to be encased in a supply system able to navigating the physique’s organic obstacles. LNPs fulfill this position, permitting the RNA to achieve the meant cells for max therapeutic affect. SCALAR goals to take this a step additional, permitting for an unprecedented three orders of magnitude scalability in LNP manufacturing charges, addressing the velocity and consistency bottlenecks that hinder present strategies.

Sarah Shepherd, the primary writer of the paper and a current Ph.D. graduate who labored within the Mitchell Lab, says, “With SCALAR, we’re not simply reacting to immediately’s challenges however proactively getting ready for tomorrow’s alternatives and crises. This expertise is versatile, makes use of mixing architectures well-documented in microfluidics, and is scalable sufficient to satisfy future calls for in actual time. That is an infinite leap ahead for the sphere.”

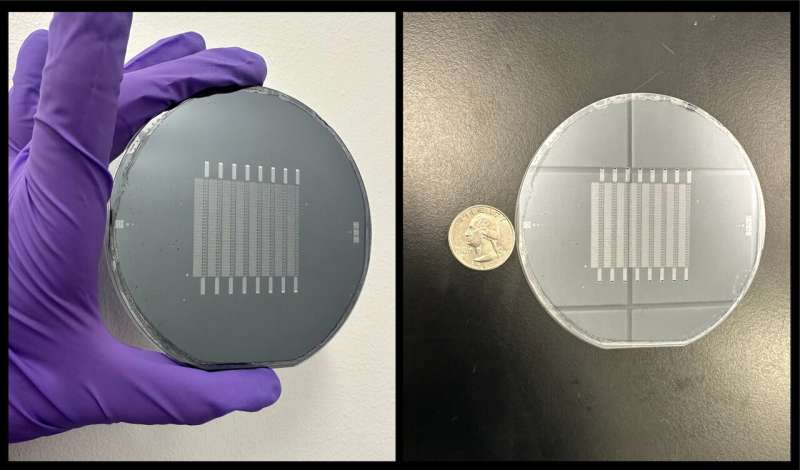

Shepherd says that SCALAR builds on prior work from the Mitchell lab and relies on a microfluidic chip platform. Akin to a pc chip, whereby a pc’s electrically built-in circuit has quite a few little transistors transporting alerts as ones or zeroes to provide an output, the SCALAR microchip exactly controls their two key reagents, lipids and RNA, to generate LNPs.

As well as, their platform can have one, 10, or 256 particular person mixing items to correspond to the needs-of-use instances starting from small-scale drug screening and improvement, to mid-scale formulations for in vivo research, to large-scale formulations for scientific purposes.

To make sure consistency throughout scales, the identical microfluidic mixing structure is used for all gadgets, and, to make sure that the 2 key reagents are uniformly distributed to every machine within the array, the group built-in excessive fluidic resistance microchannels into the design to observe beforehand established design guidelines for large-scale microfluidic gadgets. This ensures that every machine within the multi-unit array produces LNPs with an identical bodily traits, a key attribute within the tightly regulated pharmaceutical trade.

“We’re thrilled we have been ready to make use of the clear room on the Singh Middle to manufacture multi-purpose chips that may face up to the excessive warmth and harsh solvents wanted to wash the chips, making them safely reusable,” Shepherd says.

The SCALAR chips are comprised of silicon and glass, which give a number of benefits over present polymer-based platforms. Not solely do they stop material-leaching points related to these platforms, which result in contamination, however additionally they enable for sterilization at extraordinarily excessive temperatures, making them preferrred for pharmaceutical purposes. Moreover, the platform will be reset and reused, providing environmental advantages and lowering total manufacturing prices.

Whereas the researchers initially used the SCALAR platform to formulate SARS-CoV-2 spike-encoding mRNA LNP vaccines, they consider that the purposes are far broader.

“Along with fixing a present and important want within the pharmaceutical trade, Sarah’s work is a virtuosic mixture of microfabrication, microfluidic, and lipid nanoparticle applied sciences,” says co-author David Issadore, professor of bioengineering within the College of Engineering and Utilized Science at Penn. “There are only a few college students who might have pulled off one thing this formidable within the timeline of a Ph.D.”

“This expertise has the potential to turn into a cornerstone within the discipline of nanomedicine, past RNA-based therapies,” Mitchell says. “The scalability and flexibility of the SCALAR chips might nicely make them the Swiss Military knife within the RNA lipid nanoparticle pharmaceutical manufacturing device package.”

Extra info:

Sarah J. Shepherd et al, Throughput-scalable manufacturing of SARS-CoV-2 mRNA lipid nanoparticle vaccines, Proceedings of the Nationwide Academy of Sciences (2023). DOI: 10.1073/pnas.2303567120

Offered by

College of Pennsylvania

Quotation:

SCALAR: A microchip designed to remodel the manufacturing of mRNA therapeutics and vaccines (2023, August 24)

retrieved 24 August 2023

from https://phys.org/information/2023-08-scalar-microchip-production-mrna-therapeutics.html

This doc is topic to copyright. Aside from any honest dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for info functions solely.