| Aug 22, 2023 |

|

|

|

(Nanowerk Information) Epoxy resins are powerful and versatile polymers. Together with glass or carbon fibers, they’re used, for instance, to fabricate elements for plane, automobiles, trains, ships and wind generators. Such epoxy-based fiber-reinforced polymers have wonderful mechanical and thermal properties and are a lot lighter than metallic. Their weak spot: They don’t seem to be recyclable – not less than not but.

|

|

Now Empa researchers led by Sabyasachi Gaan at Empa’s Superior Fibers laboratory have developed an epoxy resin-based plastic that’s absolutely recyclable, repairable and likewise flame retardant – all whereas retaining the favorable thermomechanical properties of epoxy resins.

|

|

They’ve revealed their findings within the Chemical Engineering Journal (“Recyclable flame retardant phosphonated epoxy primarily based thermosets enabled by way of a reactive strategy”).

|

|

Recycling epoxy resins is something however trivial, as a result of these plastics are so-called thermosets. In this kind of polymer, the polymer chains are intently crosslinked. These chemical crosslinks make melting not possible. As soon as the plastic has hardened, it may possibly not be reshaped.

|

|

This isn’t the case for thermoplasts, reminiscent of PET or polyolefins. Their polymer chains lie shut collectively however should not chemically linked to one another. When heated, these polymers may be melted and fashioned into new shapes. Nevertheless, due to the dearth of crosslinks, their mechanical properties at elevated temperatures are typically not so good as these of thermosets.

|

|

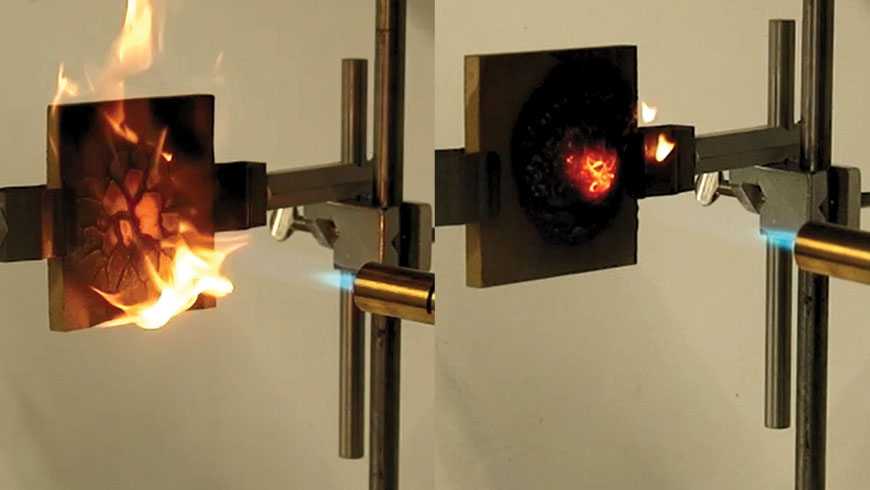

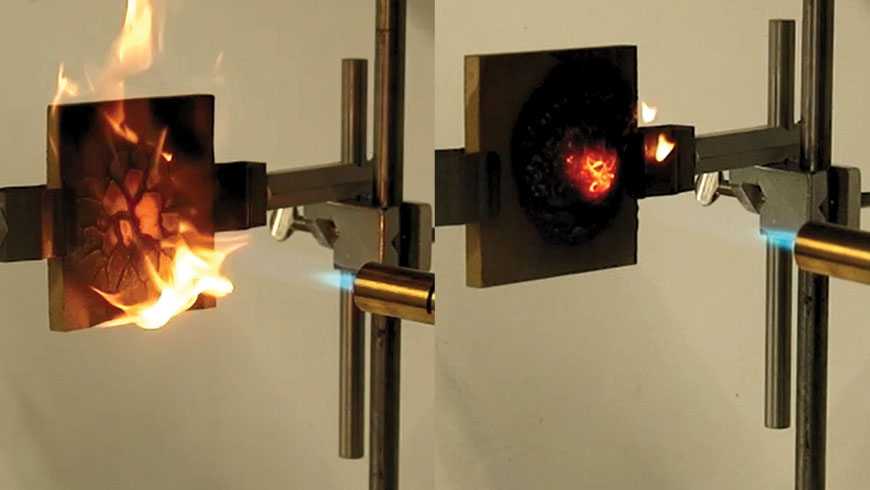

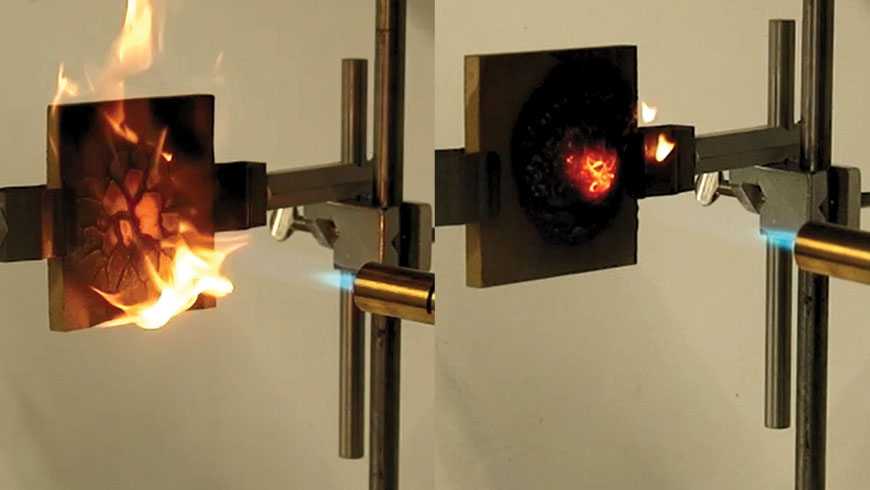

| The brand new epoxy resin is flame retardant because of its phosphorus content material, as seen on this burn check of an untreated MDF pattern (left) in comparison with a pattern coated within the new polymer. (Picture: Empa)

|

A brand new type of polymer

|

|

The distinctive epoxy resin that the Empa researchers have developed in collaboration with nationwide and worldwide companions is technically a thermoset – however not like different thermosets, it may be reshaped like a thermoplast. The secret is the addition of a really particular useful molecule from the category of phosphonate esters into the brand new resin matrix.

|

|

“We initially synthesized this molecule as a flame retardant,” says co-inventor of this expertise and Empa scientist Wenyu Wu Klingler. Nevertheless, the bond the molecule varieties with the polymer chains of the epoxy resin is dynamic and may be damaged below sure circumstances. This loosens the crosslinking of the polymer chains in order that they are often melted and reshaped.

|

|

Such supplies, often known as vitrimers, have solely been identified for about ten years and are thought of significantly promising.

|

|

“Right now, fiber-reinforced composites should not recyclable in any respect, besides below very harsh circumstances, which injury the recovered fibers,” explains Wu Klingler. “As soon as they’ve reached the top of their service life, they’re incinerated or disposed of in landfills. With our plastic, it could be doable for the primary time to deliver them again into circulation once more.”

|

|

“Our imaginative and prescient for the longer term,” provides group chief Sabyasachi Gaan, “is a composite materials, by which each the fibers and the plastic matrix may be fully separated and reused.” The researcher sees a chance in carbon-fiber-reinforced plastics specifically, as they’re generally used within the building of airplanes, trains, boats, automobiles, bicycles and extra.

|

|

“The manufacturing of carbon fibers requires lots of vitality and releases an infinite quantity of CO2,” he explains. “If we may recycle them, their environmental footprint can be loads higher – and the worth loads decrease.” Furthermore, the restoration of beneficial parts like phosphorus related to the matrix polymer can be doable.

|

|

| Not often doable for thermosets: The lower within the materials may be repaired by making use of warmth and strain. (Picture: Empa)

|

A fabric made to measure

|

|

Fiber-reinforced composites should not the one utility for the brand new polymer. For instance, it might be used to coat picket flooring, as a clear, resistant layer that has good flame-retardant properties – and the place scratches and dents may be “healed” with a little bit strain and warmth.

|

|

“We did not develop a single materials for a particular objective, however relatively a toolbox,” Gaan explains. “Flame retardancy, recyclability and repairability are a given. We are able to optimize all different properties relying on the meant use.” For instance, he says, circulate traits are significantly essential for the manufacturing of fiber-reinforced plastics, whereas exterior wooden coatings must also be weather-resistant.

|

|

To pursue these and different functions of the fabric, the researchers are actually on the lookout for industrial companions. The possibilities of business success are good: Along with all its different advantageous properties, the modified epoxy polymer can be cheap and straightforward to fabricate.

|