HII’s Newport Information Shipbuilding division has harnessed the ability of additive manufacturing to supply a cutting-edge specialised device to be used aboard the USS John F Kennedy plane provider (CVN 79), which holds the potential to reshape the panorama of naval shipbuilding.

Historically, manufacturing complicated instruments for naval tasks has been a time-consuming course of, usually taking weeks to finish. Nevertheless, Newport Information Shipbuilding has shattered this paradigm by using AM know-how to create a spotface chopping device, an important part for ship upkeep. Crafted by device engineer Chris Davis, the device’s design, often wrought via typical means, was fast-tracked with AM.

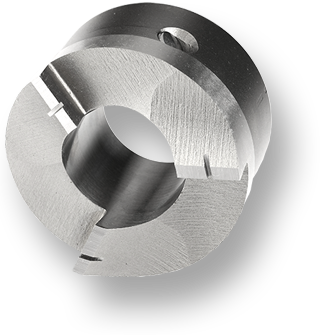

You’ll be able to see a typical old-school spotface device within the picture under. We do not know how large the one which HII has developed is, however the picture provides you some concept of what the device does.

The catalyst behind this growth was Deputy Chief Engineer John Ralls and his AM staff. Ralls emphasised that AM presents an unparalleled benefit in swiftly producing intricate instruments with out compromising precision. The digital design conceived by Davis was translated right into a tangible device inside mere days, defying conventional manufacturing timelines.

“This device instance demonstrates the good thing about long-term strategic considering,” stated Ralls.

“Newport Information Shipbuilding has taken a management position in particular applied sciences, Additive Manufacturing being one in every of them. We’ve eliminated quite a few roadblocks which have enabled us to assist emergent elements like this spotface chopping device.”

The device’s novel building incorporates carbide inserts, which will be simply rotated or changed—an innovation that supersedes the older, labor-intensive metal cutters necessitating frequent sharpening. With this improve, the spotface chopping device is just not solely environment friendly but in addition cost-effective, anticipated to avoid wasting a considerable variety of man-hours throughout CVN 79’s operations.

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t neglect to join our weekly additive manufacturing publication to get all the most recent tales delivered proper to your inbox.