PHILIP LING | Avnet

Manufacturing facility automation methods are benefiting now from a number of applied sciences and their enabling components.

Automation has an extended historical past, and it has performed a necessary function in all industrial markets. Repeatable manufacturing to top quality and in excessive quantity is the essence of industrialization. The price of the completed product may be instantly associated to the extent of automation within the manufacturing course of.

Steady developments in automation ship mechanical excellence. That excellence, in flip, depends on management. Producers should steadiness applied sciences used to implement management to this stage with business concerns. These embody the price of growth and deployment – or capital expenditure – and the recurring price of implementation – or operational expenditure.

New applied sciences can impression manufacturing unit automation when producers align capex and opex whereas precisely assessing whole price of possession. This text examines some applied sciences that meet this requirement and a few which will affect the route of automation.

Industrial automation applied sciences

A number of applied sciences with their corresponding enabling components are impacting industrial automation proper now. The aggressive benefit of Industrial Web of Issues (IIoT) will enhance as these applied sciences turn into extra pervasive.

- Single-pair Ethernet

- Edge computing

- Time-sensitive networking

Single-pair Ethernet in industrial automation

Broad space networking (WAN) has modified each facet of contemporary life. Shoppers take pleasure in web entry anyplace, even on a transatlantic flight. Its use in IIoT means info know-how and operational know-how are colliding, and the best way connectivity is used continues to be creating. Completely different components of the ecosystem are at completely different levels of their IIoT journey.

The commercial sector is now largely aligned on the usage of Ethernet to help an IP structure. There may be additionally rising momentum behind single-pair Ethernet (IEEE 802.3cg) in industrial automation. The transfer to single-pair Ethernet (SPE), which the automotive market developed, gives a simplified community on the bodily stage. It presents each information and energy on the identical two wires, speeds of 10 Mbps, reaches of 1000 meters, and help for multidrop configuration.

The event of SPE helps to convey Ethernet into an atmosphere the place single-pair connectivity has lengthy been the popular resolution. SPE’s significance will enhance as help grows. An instance of that is the superior bodily layer (APL) developed by leaders within the industrial sector. Ethernet-APL makes use of the 10BASE-T1L a part of the usual, plus extensions. Ethernet-APL covers bodily layer attributes, together with energy, connectors and cables. The Ethernet-APL layer can also be specified to be used in hazardous areas.

The Ethernet-APL group includes OPC Basis, Profibus, FieldComm Group, and OVDA. The bodily layer helps varied high-level community protocols, together with EtherNet/IP, HART-IP, OPC UA, and Profinet.

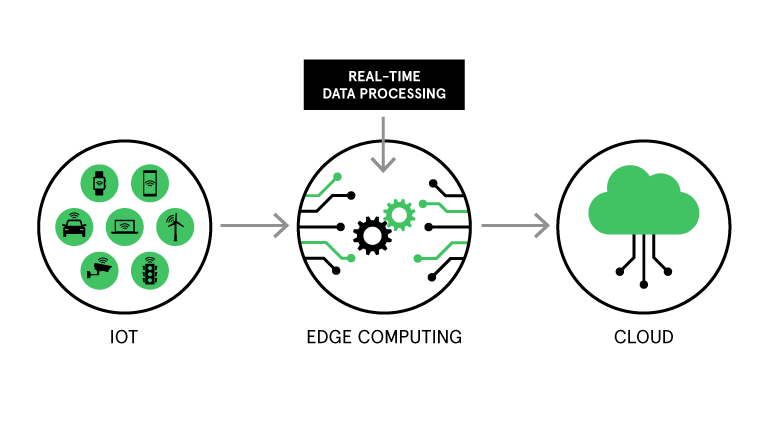

Edge computing

The IIoT launched cloud computing to the manufacturing unit ground. Cloud platforms play an essential function in information aggregation, its evaluation and distribution to back-office purposes. Edge computing places the facility of the cloud instantly on the manufacturing line.

An edge computing resolution employs high-end processors working cloud-level software program on an area system. That system connects on to the manufacturing tools. There are a number of the explanation why edge computing is common.

First, it permits a few of, or all, the operational information to remain contained in the group’s partitions. There are good safety imperatives for taking this strategy. An additional purpose is to easily decrease the price of transferring information round. One other is to keep away from the latency related to processing time-sensitive information in a cloud platform.

Second, edge computing creates a contained atmosphere that permits producers to take better management over their processes. This work cell strategy can help distributed and separate workflows that present better flexibility over how property are deployed. An edge pc can flip a small cluster of machines right into a discrete manufacturing course of that may function exterior a wider manufacturing atmosphere.

The idea of edge computing goes past securing information or minimizing cloud transfers. It helps developments similar to micromanufacturing or on-demand manufacturing.

Edge computing in industrial automation

Time-sensitive networking

Because the IT and OT networks proceed to merge, the necessity for time-sensitive networking (TSN) has elevated. The IEEE Requirements Affiliation is engaged on a number of profiles for time-sensitive networking in varied verticals, together with industrial automation.

The aim of the specification is to help time-critical packets on an Ethernet community. It achieves this utilizing three mechanisms. The primary is a technique to prioritize Ethernet frames which can be time crucial by delaying frames that aren’t. Transmission time is one instrument used to set priorities. It additionally seems to be on the body size to find out if it may be despatched with out disrupting increased precedence visitors. An additional technique is to construct fault-tolerant networks with a number of paths to keep away from latency.

Semiconductor producers are actually implementing these options on the chip stage. Multi-chip options are evolving into single-chip or system-on-chip product choices. This can proceed in parallel with efforts to maneuver to straightforward utility protocols.

Anticipate the fee and complexity of implementing TSN to return down fairly quickly. Not all producers will see a profit or want for TSN, no less than not instantly. As IIoT pervades the manufacturing atmosphere, TSN is more likely to function extra strongly.

Applied sciences that may impression manufacturing unit automation

Industrial tools has an extended operational lifetime. This implies change may be gradual compared to different markets. For example, wi-fi mesh networks are nonetheless largely restricted to connecting sensors in an industrial atmosphere. Wired connectivity continues to be dominant for management.

Nevertheless, there may be additionally extra cross-pollination between verticals, inspired by large space networking. Most of the applied sciences which have been created in – or are depending on – IT are making their manner into the OT world. A number of the outstanding and most promising applied sciences embody:

- Digital twins

- Blockchain

- Microservices

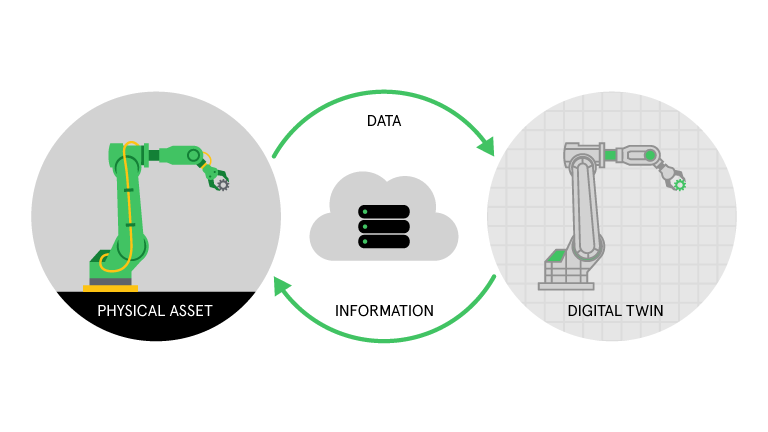

Digital twins

The thought of working duplicate programs, or twins, in numerous environments goes again to NASA’s early days. A twin can be utilized to duplicate and react to operational information occurring some place else, even off planet. Transferring to the digital area has enabled the idea to be extra price environment friendly and, doubtlessly, extra versatile.

Digital twinning includes modelling an motion, reasonably than simulating it. The distinction depends on the dual utilizing real-world information. That is the place IoT applied sciences play an element. Sensors are the first supply of information.

It turns into possible to make use of digital twins as producers deploy extra sensors on industrial tools and couple them with high-speed networking.

Current developments point out OEMs are actually implementing digital twins at a piece cell stage. This makes it simpler to mannequin a part of a system as a perform, reasonably than making an attempt to mannequin a complete manufacturing unit.

Utilizing a number of digital twins will turn into extra widespread with the event of edge processing. It follows that the 2 are intently coupled, as edge processing is efficient at an area stage. Though edge processing isn’t depending on digital twinning, the symbiosis is obvious.

Blockchain

In a producing atmosphere, the time period “blockchain” may be intently related to provide chain. Engineers have mentioned the idea of utilizing blockchain know-how to authenticate and observe the merchandise within the provide chain for a number of years.

A part of the potential in adopting IoT comes from the commercialization of knowledge. Belief will probably be an essential a part of the success. Utilizing blockchain to supply proof of authenticity could possibly be key.

The transfer towards offering one thing as a service can also be constructing momentum. Right here, blockchain could possibly be used to validate the {hardware} platform delivering that service. If the service depends on real components being fitted to a system, blockchain could possibly be the easiest way of authenticating these components.

Microservices

If a theme is rising in industrial automation’s evolution, maybe it’s round making work cells extra clever. Edge computing and shortly digital twins are targeted on work cells and modular performance.

Modularity at a software program stage is one technique to describe microservices. The methodology is now widespread in cloud platforms. A microservice structure is extra agile, extra scalable and simpler to take care of than massive monolithic software program constructions.

The variety in industrial automation processes suggests microservices will turn into extra widespread right here, too. Flexibility on the store ground will imply machines may be repurposed extra continuously. Utilizing a microservice strategy will help that flexibility.

AI in industrial automation

There may be huge scope for AI to impression industrial automation. Present examples of AI display that the know-how is nice at following procedures and adapting inside recognized parameters. Its actual energy comes from reacting to the sudden in a predictable manner.

Utilizing AI on this manner ought to enhance procedural operations which can be dealt with by programmable logic controllers (PLCs). AI also can now write the ladder logic that configures the PLCs. This situation makes use of AI in a mechanical technique to increase a perform.

Placing AI into human-centric operations often is the subsequent section. On this situation, the AI would wish to “suppose” like an operator. It could at first help and, doubtlessly, in time displace the human within the loop.

Conclusion

Industrial automation is continually creating. New applied sciences, usually from different market verticals, present the momentum for enchancment. Warning is all the time used, however the tempo of change appears to be growing.

Research present a widening productiveness hole between massive OEMs that may afford to implement new applied sciences extra aggressively than smaller enterprises. As entry to those applied sciences improves and the overall price of possession softens, this hole might as soon as once more shut.