Nominations at the moment are open for the 3D Printing Trade Awards 2023. Who’re the leaders in 3D printing? Discover out on November thirtieth when the winners throughout twenty classes shall be introduced throughout a London-based reside awards ceremony.

Additive manufacturing knowledge specialist Senvol has demonstrated a novel machine studying (ML) strategy to materials allowables, with the corporate’s ML software program precisely predicting materials efficiency.

Senvol was awarded this contract to use its machine studying software program, Senvol ML, to facilitate a path to speedy growth of fabric property allowables for additive manufacturing. This work was carried out as a part of a US Authorities contract W911NF-20-9-0009.

The agency’s strategy is claimed to be less expensive, versatile, and time-effective than the traditional Metallic Supplies Properties Growth and Standardization (MMPDS) strategy to materials allowables growth.

Senvol partnered with EWI and Pilgrim Consulting as a part of this system. Personal non-profit analysis and growth (R&D) agency Battelle and Hector Sandoval, an LM Fellow at Lockheed Martin, served as technical advisers. The contract was administered by the Nationwide Middle for Manufacturing Sciences (NCMS) by means of the AMMP Different Transaction Settlement (OTA) program.

“Materials allowables growth is a really costly and time-consuming endeavor,” commented Senvol President Annie Wang. “Senvol’s program was very profitable in demonstrating a brand new strategy to additive manufacturing allowables growth that leverages machine studying. We had been very happy with the outcomes and look ahead to continued work on this innovative space.”

Dr. William E. Frazier, retired Chief Scientist for Air Automobile Engineer at NAVAIR and President of Pilgrim Consulting LLC, added: “I used to be very happy to hitch Senvol’s staff for this program. Senvol’s machine learning-enabled strategy straight addresses a serious trade problem: the speedy and cost-effective growth of additive manufacturing materials property allowables.”

Optimizing materials allowables growth with ML

While additive manufacturing allows the light-weight and time-effective manufacturing of designs, Senvol claims that these advantages are restricted by the point and excessive price necessities of allowables growth.

This excessive price is essentially attributable to the truth that materials allowable growth requires a considerable quantity of empirical knowledge to be generated at a set processing level. As such, all empirical knowledge usually must be generated from scratch each time there’s a main change within the course of. This makes additive manufacturing processes pricey and time-consuming each throughout preliminary implementation, and within the long-term when there are inevitable adjustments to the 3D printing process.

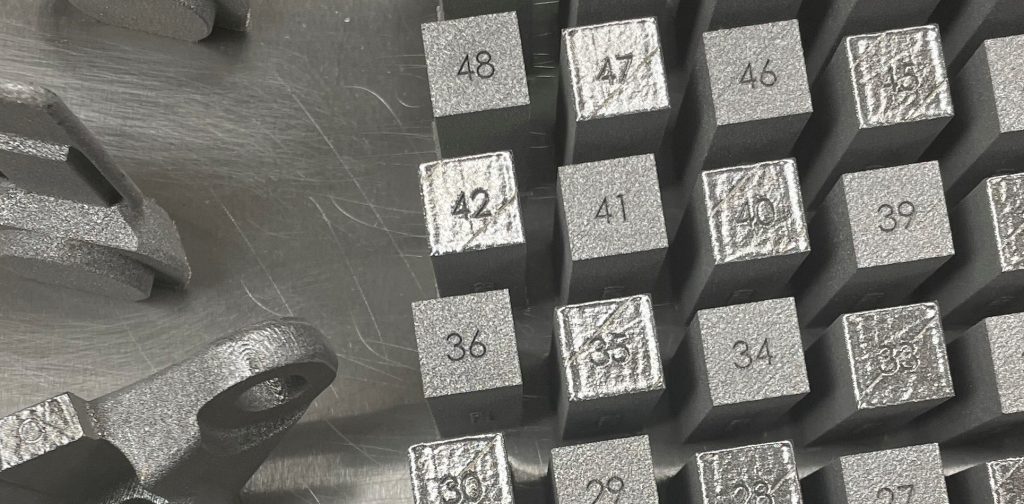

By way of this program, Senvol demonstrated a novel strategy to materials allowables growth that leverages machine studying. This system centered round a 17-4 PH Stainless Metal materials, processed through a powder mattress fusion 3D printer.

Senvol’s ML software program, which helps the qualification of additive manufacturing processes, was leveraged in this system to develop statistical substantiated materials properties corresponding to materials allowables. The software program achieved this whereas concurrently optimizing knowledge technology necessities.

In response to Senvol, this machine studying strategy is versatile, and might deal with adjustments to the AM course of. Certainly, the corporate’s ML software program will be utilized to any additive manufacturing course of, any 3D printer, and any materials. This makes the strategy superb for long-term sustainment.

“The usage of machine studying for additive manufacturing processes and materials growth could be very mature. This has been adopted by trade and is the low-hanging fruit. The usage of machine studying particularly for materials allowables growth, nevertheless, remains to be a piece in progress,” defined Senvol President Zach Simkin.

“I’m happy that we now have now made two profitable demonstrations of the machine studying strategy to allowables – as soon as on this program utilizing a steel alloy and evaluating to MMPDS, and as soon as in a previous program funded by America Makes that used a polymer materials and in comparison with CMH-17 – however extra analysis is required.”

“The upside is great, and we look ahead to persevering with to accomplice with the Authorities and trade to advance work on this space,” added Simkin.

It must be famous that the venture didn’t develop true allowables. Furthermore, price range and programmatic eating places meant that the venture staff needed to make a number of simplifying choices.

AI and ML software program in additive manufacturing

Plenty of corporations inside additive manufacturing at the moment are incorporating AI and ML capabilities into their software program choices. One such firm is London-based Ai Construct, which affords ML and AI pushed toolpath technology and automatic high quality assurance by means of its AiSync software program.

In a current interview with 3D Printing Trade, Ai Construct’s Business Director Luke Rogers emphasised the significance of ML capabilities in offering automated high quality management. Rogers defined that, inside large-format 3D printing, there’s usually solely a 40% success price when 3D printing a component for the primary time. In response to Rogers, “utilizing machine studying, and mixing that again into the preliminary toolpath, you’ll be able to simply stand up into the 90% plus first-time print success price.”

Elsewhere, throughout RAPID + TCT 2023 Montreal based mostly excessive temperature 3D printer producer AON3D supplied a primary take a look at its new machine learning-driven thermal optimization software program.

A core know-how simulation engine constructed particularly for Materials Extrusion (MEX), this device offers quick and correct predictions on warmth circulation conduct inside an object in the course of the 3D printing course of. The corporate claims that this software program affords the potential for price slicing, improved half reliability and consistency, efficiency optimization and higher technical resolution making.

Subscribe to the 3D Printing Trade e-newsletter to maintain updated with the newest 3D printing information. You may as well observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing trade? Go to 3D Printing Jobs to view a number of obtainable roles and kickstart your profession.