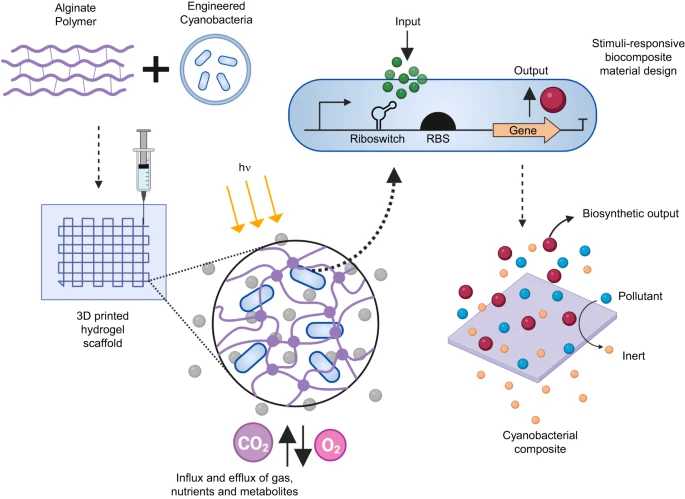

Researchers on the College of California San Diego have launched an additively manufactured innovation in water air pollution remediation. They’ve created an “engineered dwelling materials,” a 3D printed construction composed of a seaweed-based polymer mixed with genetically engineered micro organism, which has the potential to make water purification extra eco-friendly.

The magic behind this dwelling materials lies in its genetically modified micro organism, able to producing enzymes that may remodel numerous natural pollution into innocent substances. Moreover, these micro organism can self-destruct within the presence of theophylline, a molecule generally present in tea and chocolate, guaranteeing their secure elimination after their process is full.

The synergy of biology and supplies science has resulted in an innovation that surpasses conventional artificial supplies. This dwelling materials’s design features a grid-like construction, optimizing the micro organism’s proximity to the floor, thereby enhancing nutrient, fuel, and light-weight entry. This elevated floor space additionally enhances its decontamination effectivity.

As a proof of idea, the researchers efficiently employed this materials to decontaminate indigo carmine, a textile business dye pollutant. Notably, they’ve devised a technique for the micro organism to self-destruct with out exterior chemical intervention, a vital step for environmental security.

This analysis opens the door to environmentally responsive supplies with a big selection of potential purposes. With interdisciplinary collaboration between materials scientists and biologists, there may be nice potential for novel supplies that reply to current environmental cues. The event of supplies that may effectively and autonomously fight air pollution is a step nearer to reaching a cleaner, greener planet.

You may learn the complete paper titled “Phenotypically Advanced Dwelling Supplies Containing Engineered Cyanobacteria” at this hyperlink.

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t overlook to enroll in our weekly additive manufacturing e-newsletter to get all the most recent tales delivered proper to your inbox.