It is a sponsored article dropped at you by Siemens.

Massive information, Trade 4.0, IIoT, Edge Know-how, and the Cloud are all phrases we all know. Whether or not you’re a machine device builder, a job store or contract producer, you’re desirous about digitalization and one of the best ways to get began.

Whether or not you’re a machine device builder, a job store or contract producer, you’re desirous about digitalization and one of the best ways to get began.Siemens

Whether or not you’re a machine device builder, a job store or contract producer, you’re desirous about digitalization and one of the best ways to get began.Siemens

For the machine builder, it’s about managing huge information from the machine, lowering time-to-market, and utilizing the latest expertise to create sensible machines. These are cognitive computing programs, which means they will make selections and remedy issues with out the assistance of a human. That is the place synthetic intelligence (AI) enters the equation, because the machine learns from what it does.

As well as, machines have to be prepared to interact the Web of Issues (IoT) to achieve success within the present market. Machine builders nonetheless promote on the options and advantages of their machines, however this isn’t the one solution to distinguish themselves from the competitors.

How digital twins cut back prices and downtime

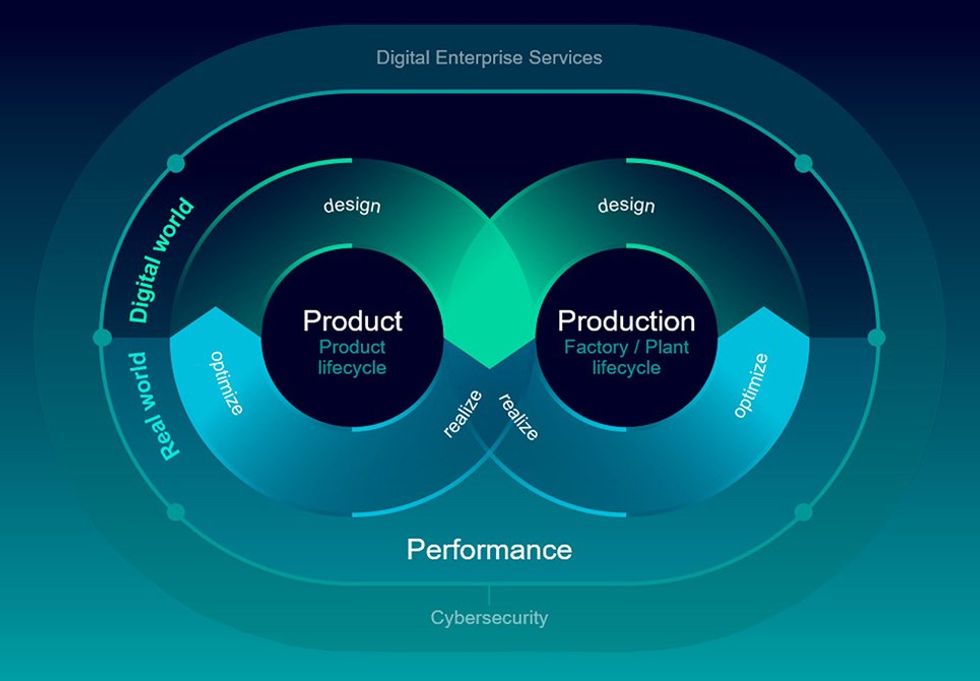

The digital twin idea in machine improvement permits simulation of a machine device not solely in its design, but in addition in its bodily efficiency, earlier than the machine is even began bodily.

With the digital twin, each situation on the machine is simulated in real-time, with suggestions to the design loop. That approach, engineers don’t have to waste time on the shopfloor or in a take a look at middle as they’ve finished beforehand, with the “trial and error” technique.

The science has developed, so the construct course of should likewise.

For CNC customers, the digital twin permits a machine store to be IoT-ready.Siemens

For CNC customers, the digital twin permits a machine store to be IoT-ready.Siemens

CNC machine customers want their machines to be sensible, as effectively — speaking with one another and the management middle of their store or in a big manufacturing facility. Assume you’ll be able to’t implement digitalization since you’re a small machine store? Assume once more. Key efficiency indicators (KPIs) will be established and achieved sooner when it comes to manufacturing, machine run time, upkeep, and even power use.

When CNC is IoT-ready

For CNC customers, the digital twin permits a machine store to be IoT-ready. The upper-end software program permits real-time adjustment in-process, the whole lot from cycle time to device tip place or device journal loading for the following jobs, to facilitate each sooner startup and precision workflow.

This may be achieved with a reliable digital crew that’s each in-tune with the present expertise and tips on how to implement it in a specific atmosphere. If wanted, take time to discover a system integrator in your space (we have now a nationwide community of answer companions) that may give you related technical and business data. That is important to your success.

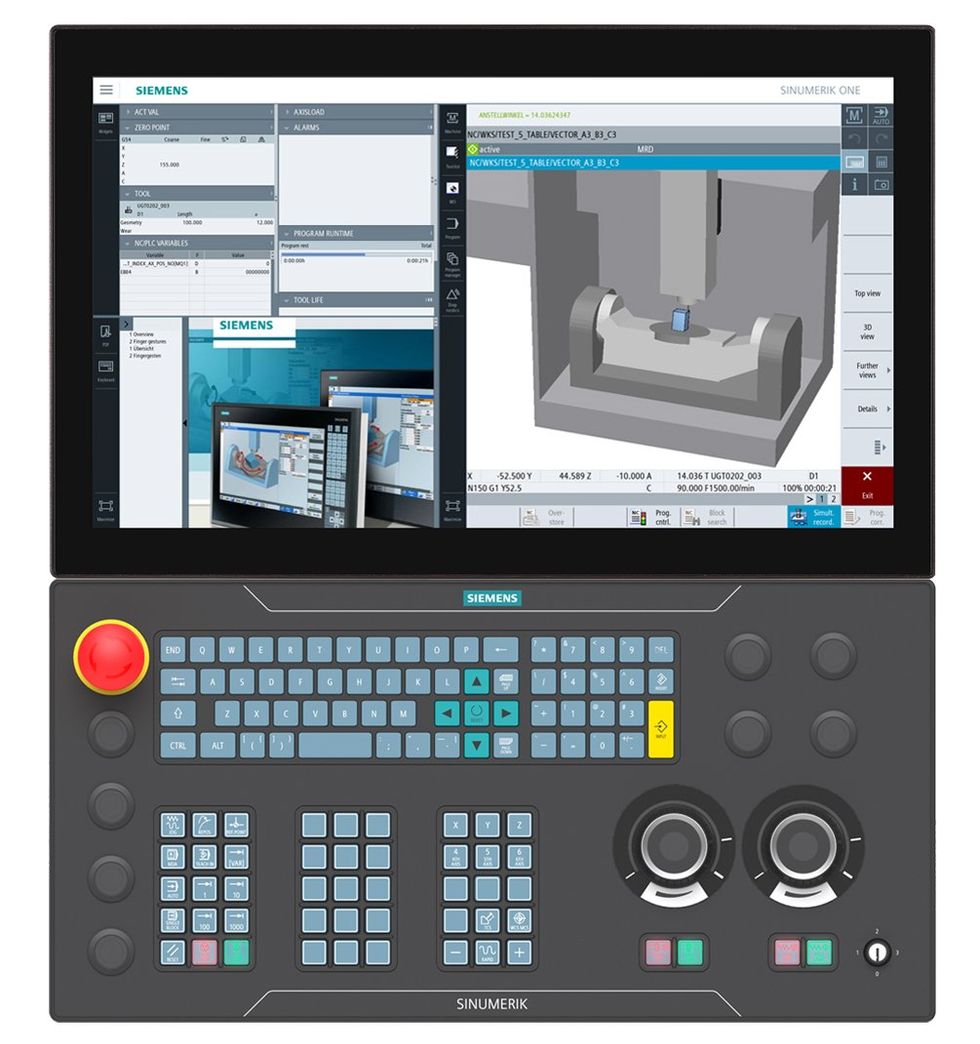

The most recent digital-native CNC from Siemens, SINUMERIK ONE, for instance, will open the following chapter within the machine device world’s journey in the direction of digitalization.Siemens

The most recent digital-native CNC from Siemens, SINUMERIK ONE, for instance, will open the following chapter within the machine device world’s journey in the direction of digitalization.Siemens

Our latest digital-native CNC, SINUMERIK ONE, for instance, will open the following chapter within the machine device world’s journey in the direction of digitalization. It options the most recent energy and software program choices to permit growth, because the job quantity will increase, or the complexity of the work will increase for you.

Just about, it gives the machine builder and end-user whole flexibility to maneuver from the CAD to the CAM to the CNC machining steps, then onto the digital shopfloor and right into a digital manufacturing, all earlier than the primary minimize is made on the machine.

Cybersecurity: Extra essential than ever

As ransomware assaults have develop into frequent within the industrial atmosphere, the difficulty of cybersecurity has taken on new significance. Stopping any assault means making an allowance for a number of points. One is the integrity of the community. The opposite is the impact of the wi-fi community within the plant and externally. The third, and most essential, is how efficient the protection is. Like a soccer sport, one improper transfer from a participant can adversely affect the sport plan.

Moreover, there have to be a number of layers of particular safety, in order that setup, operation and programming, upkeep and plant operations/management personnel all have completely different outlined ranges of entry to machines and information. That is typically a time-consuming,

however very worthwhile endeavor.

The manufacturing unit of the longer term

If we glance in the direction of the longer term, what we see is digitalization at primarily each stage of your manufacturing unit. This would come with robotic dealing with and the switch of supplies to the following machine. The “manufacturing unit of the longer term” wouldn’t be with out folks, nonetheless. Quite, personnel will tackle increased stage duties that don’t contain machining. Cobots and CNC will work with a human or straight with the machine intelligently.

Digitalization is right here to remain, so get began at present!

From Your Website Articles

Associated Articles Across the Internet