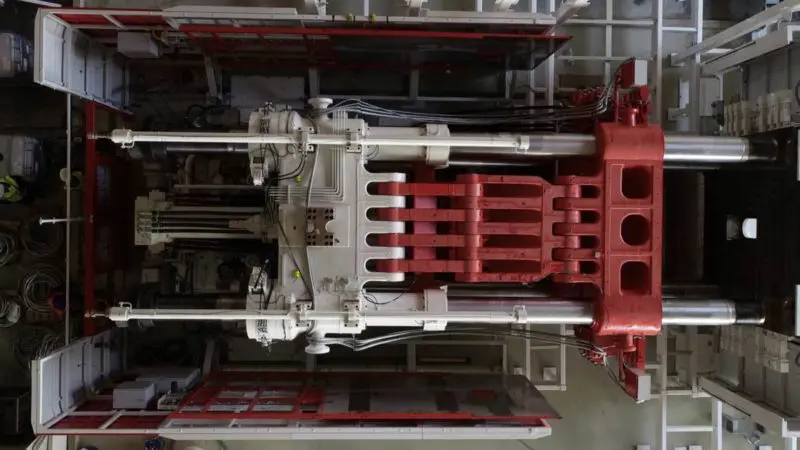

In a quiet however important transfer, Tesla is poised to redefine the panorama of electrical car (EV) manufacturing. The corporate has employed a sequence of improvements, together with the pioneering use of huge presses with as much as 9,000 tons of clamping stress in a course of often known as “gigacasting.” This method has already considerably diminished manufacturing prices for Tesla’s Mannequin Y.

Associated Story

The Mysterious 3D Printed Half within the Tesla Mannequin Y

Nevertheless, Tesla shouldn’t be stopping there. The corporate is on the cusp of yet one more breakthrough, one that might permit them to die-cast all the complicated underbody of an EV in a single piece, versus the tons of of elements usually required in standard automobiles.

Central to Tesla’s technique is 3D printing and industrial sand, each of which have performed pivotal roles in designing and testing molds for mass manufacturing. This method has enabled Tesla to create hole subframes with inside ribs, decreasing weight and enhancing crashworthiness.

Historically, automakers have prevented casting such massive constructions because of the price and dangers related to creating molds. Tesla’s method entails utilizing 3D printers that deposit a binding agent onto layers of sand to construct molds for casting molten alloys. This technique reduces prices considerably and accelerates the design validation cycle, taking solely two to a few months in comparison with the normal six months to a yr for metallic mould

Tesla’s upcoming small EV, designed for private use and robotaxi providers, provides an ideal alternative to forged a complete EV platform in a single piece, given its simplified underbody construction. Nevertheless, the selection of Gigapress know-how stays a pivotal determination, with choices starting from high-pressure machines for productiveness to slower alloy injection strategies for high quality and flexibility.

These improvements will not be solely advancing Tesla’s manufacturing capabilities but additionally have the potential to reshape all the automotive trade, making reasonably priced and sustainable EVs extra accessible to the lots.

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t neglect to join our weekly additive manufacturing publication to get all the newest tales delivered proper to your inbox.