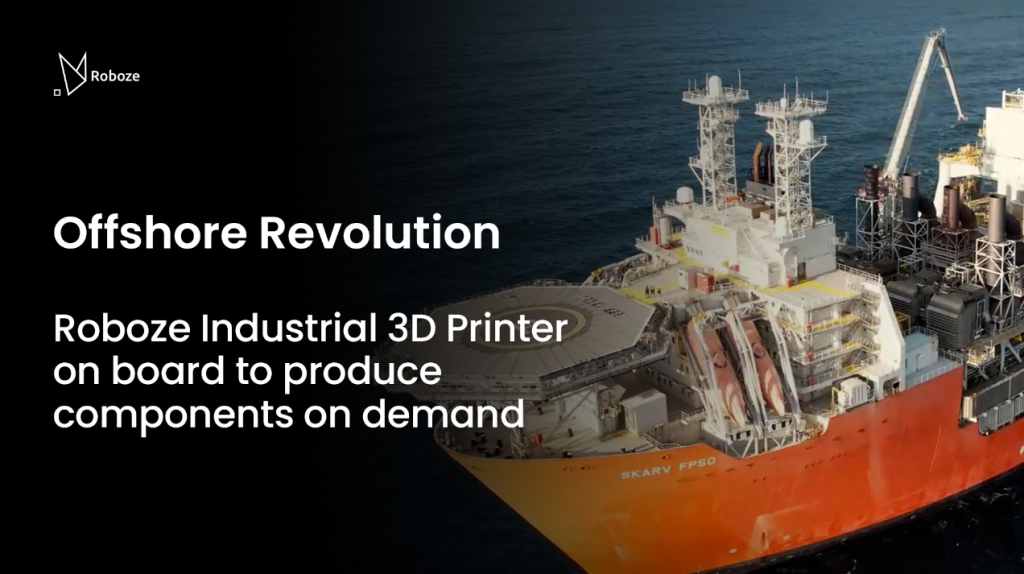

In a collaborative effort, Skarv–Aker Bp, Biesterfeld Norge As, and 3D printing firm Roboze have achieved a major milestone within the offshore trade’s digital transition.

This partnership permits the on-site and on-demand manufacturing of vital elements and spare components. Central to this development is the set up of the Roboze Plus Professional 3D printer on board the FPSO SKARV, a specialised platform for oil and fuel processing in Norway’s Skarv area. This strategic transfer straight tackles a longstanding trade problem – making certain spare components’ availability throughout deliberate and unexpected upkeep actions.

On one other observe, Roboze and Ducati Corse, the sports activities division of Ducati Motor Holding, have prolonged their partnership into 2023. This collaboration focuses on using 3D printing within the motorbike racing trade to drive technological development.

“Our partnership with Ducati Corse represents an ideal mixture between know-how and fervour for innovation,” mentioned Alessio Lorusso, CEO of Roboze. “We’re excited to proceed this collaboration and to contribute to the success of Ducati Corse via our superior 3D printing options. We’re assured that collectively we’ll obtain excellent outcomes additionally in 2023.”

Remodeling the oil & fuel trade with 3D printing

Within the context of offshore installations, the supply of substitute components is essential, whether or not for deliberate or unexpected upkeep actions. Extended shutdowns ensuing from a scarcity of spare components carry important monetary implications, additional aggravated by the constraints and prices related to space for storing. To handle this problem, the usage of Roboze’s industrial 3D printing know-how can assume a pivotal function. This strategy entails sustaining a inventory of solely uncooked supplies and producing on-demand spare components exactly when they’re required.

The video highlights the Roboze Plus Professional 3D printer’s essential function in producing elements from tremendous polymers and strengthened composites for the offshore trade. It demonstrates how this know-how is remodeling problem-solving in excessive environments. Concerning challenges, corrosion considerably contributes to grease and fuel set up shutdowns. Rising the usage of polymer elements is an efficient means to cut back this danger.

Producing elements straight on the FPSO SKARV signifies a major departure in the best way upkeep and offshore provide administration are carried out. This transformation enhances operational effectivity and minimizes environmental influence by lowering waste and enabling on-site manufacturing.

Final 12 months, Roboze and industrial manufacturing agency Siemens joined forces to develop full workflows for 3D printing industrialization. This collaboration concerned combining their experience to develop manufacturing alternatives within the vitality, mobility, and aerospace sectors via numerous digitalization and automation tasks. “For us, Siemens is a perfect associate to be much more current in these revolutionary sectors that wish to begin strategic digital transformation paths,” mentioned Francesco Pantaleone, Vice President of Enterprise Growth at Roboze.

Serving to motorsports groups achieve a aggressive edge

Through the 2022 MotoGP season, the partnership between Roboze and Ducati Corse demonstrated its significance, enabling each firms to delve into technological developments and obtain excellent outcomes. The appliance of business 3D printing and superior supplies performed a pivotal function in producing customized, aerodynamic elements, finally enhancing the efficiency of Ducati’s racing bikes.

Within the upcoming 2023 season, Roboze and Ducati Corse are extending their collaboration, specializing in advancing 3D printing options for the motorsport sector. Roboze will contribute its 3D printing know-how and novel supplies, whereas Ducati Corse will leverage its substantial experience in motorbike racing to supply useful suggestions and exact wants for 3D printing functions.

Ducati Corse will make the most of each the Roboze ARGO 500 3D printer, located in Borgo Panigale, and the Plus Professional 3D printer, positioned within the paddock. This deployment will allow it to expedite the design and manufacturing phases, successfully lowering improvement time and enhancing the bikes’ efficiency. The potential to craft tailored, light-weight, and strong elements is instrumental in preserving its aggressive benefit on the racetrack.

Elsewhere, US 3D printer producer 3D Programs and the championship-winning NASCAR workforce, Stewart-Haas Racing, introduced a three-year technical collaboration to leverage Stewart-Haas Racing’s engineering experience. Implementing 3D Programs’ ProX 800 stereolithography and Determine 4 Standalone 3D printers into its operations resulted in important developments in racecar pace and effectivity. This strategic strategy is about to reinforce Stewart-Haas’ “competitiveness throughout race days and in its ongoing dedication to innovation inside the motorsports area.”

Who will win the 2023 3D Printing Trade Awards? Make your nominations now!

What does the way forward for 3D printing for the following ten years maintain?

What engineering challenges will must be tackled within the additive manufacturing sector within the coming decade?

To remain updated with the newest 3D printing information, don’t neglect to subscribe to the 3D Printing Trade publication or observe us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you searching for a job within the additive manufacturing trade? Go to 3D Printing Jobs for a number of roles within the trade.

Featured picture reveals Roboze’s Plus Professional 3D printer to provide 3D printed components on-demand. Picture by way of Roboze.