Industrial manufacturing agency Siemens Vitality, and world certification and threat administration agency DNV, have joined forces to create a brand new industrial 3D printing high quality assurance platform.

This new platform combines Siemens’ first technology of AM Cockpit, an automatic high quality management platform for steel additive manufacturing, with DNV’s Impartial High quality Monitor (IQM) high quality assurance buyer portal.

It’s claimed that this new mixed providing supplies dependable high quality assurance all through all the additive manufacturing course of. 3D printed components could be simply in comparison with permitted grasp prints, while automated and distant course of certification can be achievable.

By industrializing this new high quality assurance platform, DNV hopes to grow to be the popular selection for digital threat administration throughout the world vitality sector.

“Succeeding in AM industrialization depends on a profitable digital transition. The mix of the AM Cockpit and the IQM is a major step ahead for additive manufacturing,” commented Klas Bendrik, DNV’s Chief Digital and Improvement Officer.

Manish Kumar, Head of enterprise growth, technique and gross sales at Siemens, added that, “With many years of expertise in industrializing additive manufacturing, Siemens Vitality is a wonderful accomplice for DNV in advancing high quality assurance of additively manufactured components.”

Efficiently combining two platforms

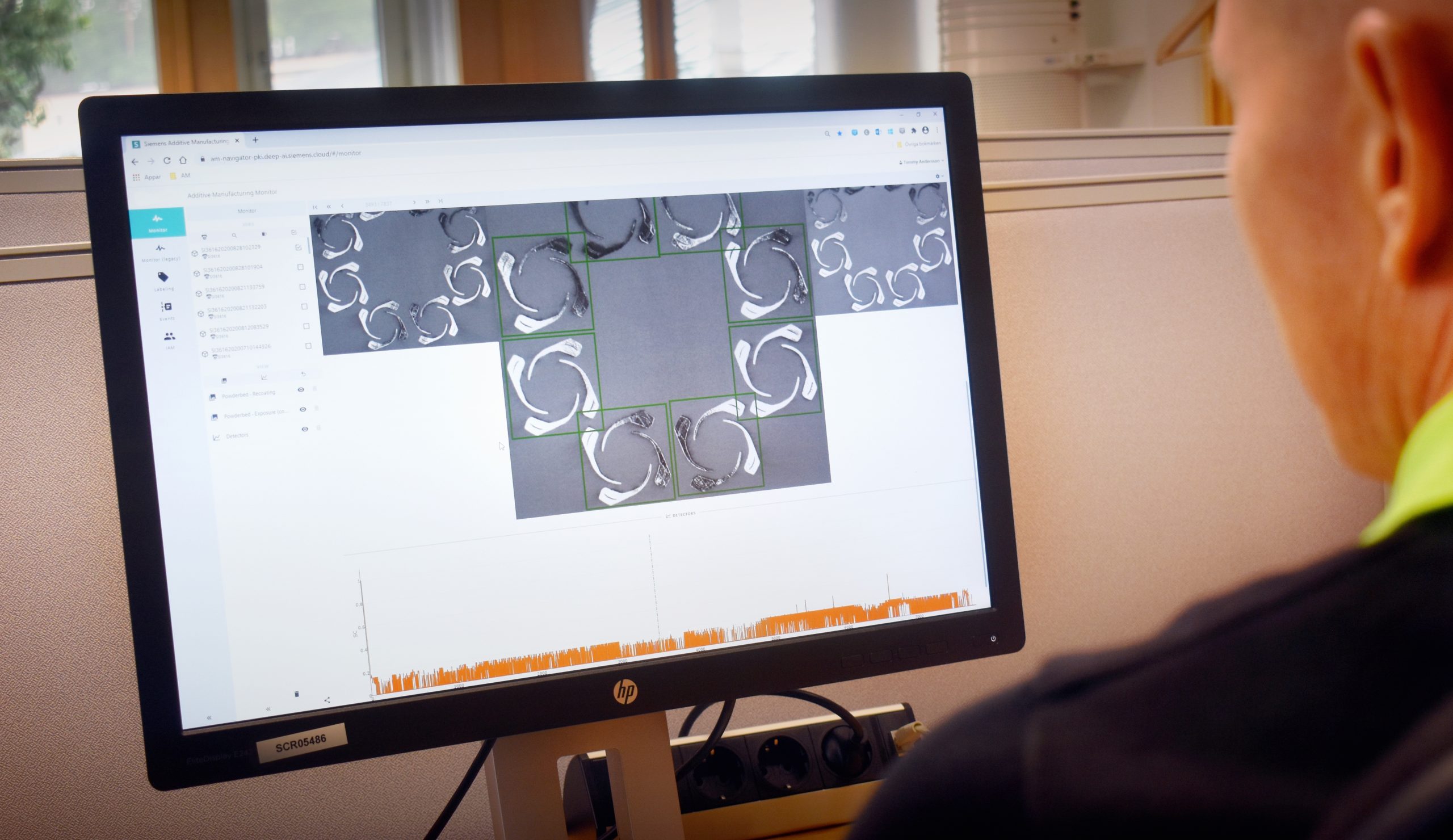

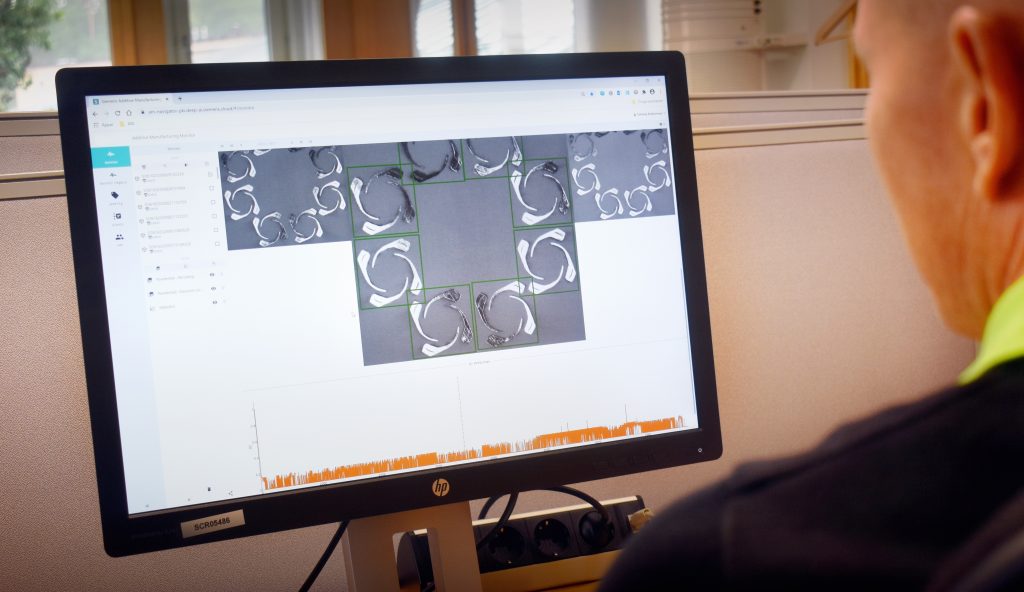

The brand new Siemens AM Cockpit platform provides detailed information assortment all through the powder mattress fusion manufacturing course of. Sensor information streams and powder mattress pictures are collected all through manufacturing, with AM Cockpit then producing a digital abstract of every 3D printed half. Right here, any problematic areas of a 3D print are highlighted for the consumer.

NDV’s IQM, developed in parallel to AM Cockpit, was produced as a part of InterQ, an EU-project aimed toward reaching zero-defect manufacturing. This platform makes use of newly developed algorithms and compliance logic to constantly monitor and validate information high quality.

By combining these two choices right into a singular digital platform, customers can monitor and visualize the printing course of, concurrently receiving digitized high quality assurance. This mix is alleged to extend confidence in closing 3D printed components, and supply assurance that the 3D printing course of meets vital high quality requirements.

This new platform has additionally been highlighted as providing potential in terms of vitality transitions, and supporting decarbonisation. Certainly, Siemens is a key world participant on this area, designing and 3D printing gasoline turbine parts that are stated to allow elevated energy plant effectivity and cut back carbon emissions. “Due to its design freedom, AM is the core know-how that enables Siemens Vitality to develop and modify gasoline generators to run on inexperienced fuels, resembling hydrogen,” claims Hans Holmström, CEO of Siemens Vitality in Sweden.

High quality assurance and additive manufacturing

Siemens and DNV’s joint platform is the most recent in an extended line of high quality assurance choices throughout the additive house.

Final 12 months’s Formnext commerce present noticed MakerVerse and ZEISS announce new high quality assurance capabilities on the MakerVerse platform, with the addition of ZEISS’s unique metrology know-how. High quality assurance options supplied by ZEISS embody Tactile CMM, Optical 3D Scan, Industrial CT- and X-Ray Options, and Floor Roughness measurement instrument. On the time, MakerVerse CEO Dr. Markus Seibold outlined how this partnership “is the proper answer for our clients needing industrial-grade high quality inspections and studies for his or her AM components.”

Extra just lately, in March of this 12 months, 3D printing software program and providers supplier Materialise launched its Course of Management Software program for steel 3D printing and the Construct Processor Software program Improvement Package (BP SDK). The Course of Management platform provides automated evaluation and correlation of layer information from the 3D printing course of. This enables customers to establish potential points previous to post-processing and high quality inspection, which may in any other case add 30% to 70% to half manufacturing prices. What’s extra, the BP SDK permits customers to switch construct settings. This allows better management over print job pace, and attributes resembling floor high quality and density.

Subscribe to the 3D Printing Trade publication to make sure you sustain with the most recent 3D printing information. You may as well observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing trade? Go to 3D Printing Jobs to view a choice of obtainable roles and kickstart your profession.