Delicate robots have lengthy been constructed utilizing artificial polymers, rubbers, and plastics, however considerations about their environmental influence have sparked a quest for extra sustainable options. In a brand new improvement, a crew of interdisciplinary researchers at Carnegie Mellon College has pioneered a novel methodology of fabricating biodegradable actuators for marine functions utilizing supplies derived from frequent brown seaweeds.

Seaweed Bio-ink

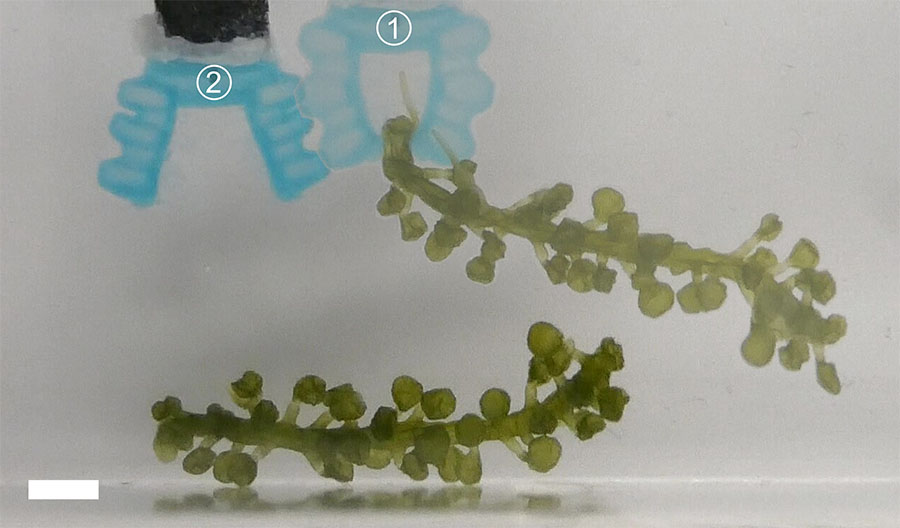

Led by college members Victoria Webster-Wooden and Adam Feinberg, in collaboration with Carmel Majidi and Lining Yao, the crew harnessed the ability of the FRESH Printing methodology to create water-tight constructions with distinctive properties. By using a bio-ink derived from seaweed, they efficiently developed small-scale, extremely versatile actuators able to extending, bending, and twisting. These actuators will also be mixed to kind constructions for gripping and positioning.

The innovation lies within the seaweed-based inks, which make the most of calcium to crosslink and kind gels. This attribute permits the actuators to alter form and stiffness by adjusting the diploma of crosslinking. Furthermore, the actuators exhibit spectacular biodegradability, breaking down in pure ocean situations inside a mere seven days. Notably, they’re additionally secure for marine organisms to devour, minimizing the danger to the setting if misplaced or broken.

Beneath the steering of Webster-Wooden, Feinberg, Majidi, and Yao, MS-BRIDGE Fellow Avery Williamson and GEM College Fellow Ravesh Sukhnandan are pushing the boundaries of actuator efficiency in pure environments whereas exploring the enlargement of this printing method to finish robotic constructions.

“We’re very excited to develop the fabrication functionality of the FRESH Printing methodology and optimize it for gentle robotic functions,” mentioned Wenhuan Solar, a current Ph.D. pupil in mechanical engineering.

“The distinctive advantages of FRESH make it potential to create robotic constructions with a mix of surprising properties.”

By bridging the hole between superior gentle robotic constructions and environmental sustainability, the crew’s biodegradable actuators supply a promising resolution. The continuing improvement of those eco-friendly applied sciences signifies a step ahead in creating instruments and strategies with clear sustainable functions.

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t overlook to enroll in our weekly additive manufacturing e-newsletter to get all the most recent tales delivered proper to your inbox.