Texas-based firm Hive3D Builders has not too long ago unveiled a carbon-neutral materials that serves as a stronger various to conventional cement. Their new substance has the potential to cut back development’s CO2 emissions by a staggering 93%, making additive manufacturing much more sustainable and paving the best way for a worldwide development revolution.

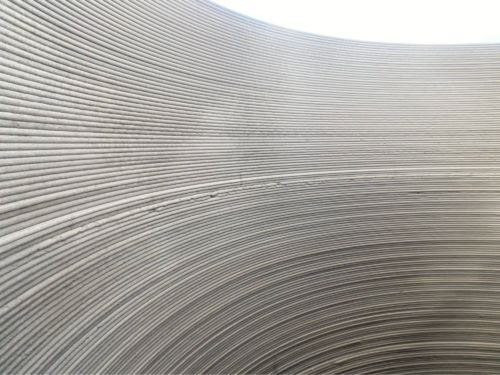

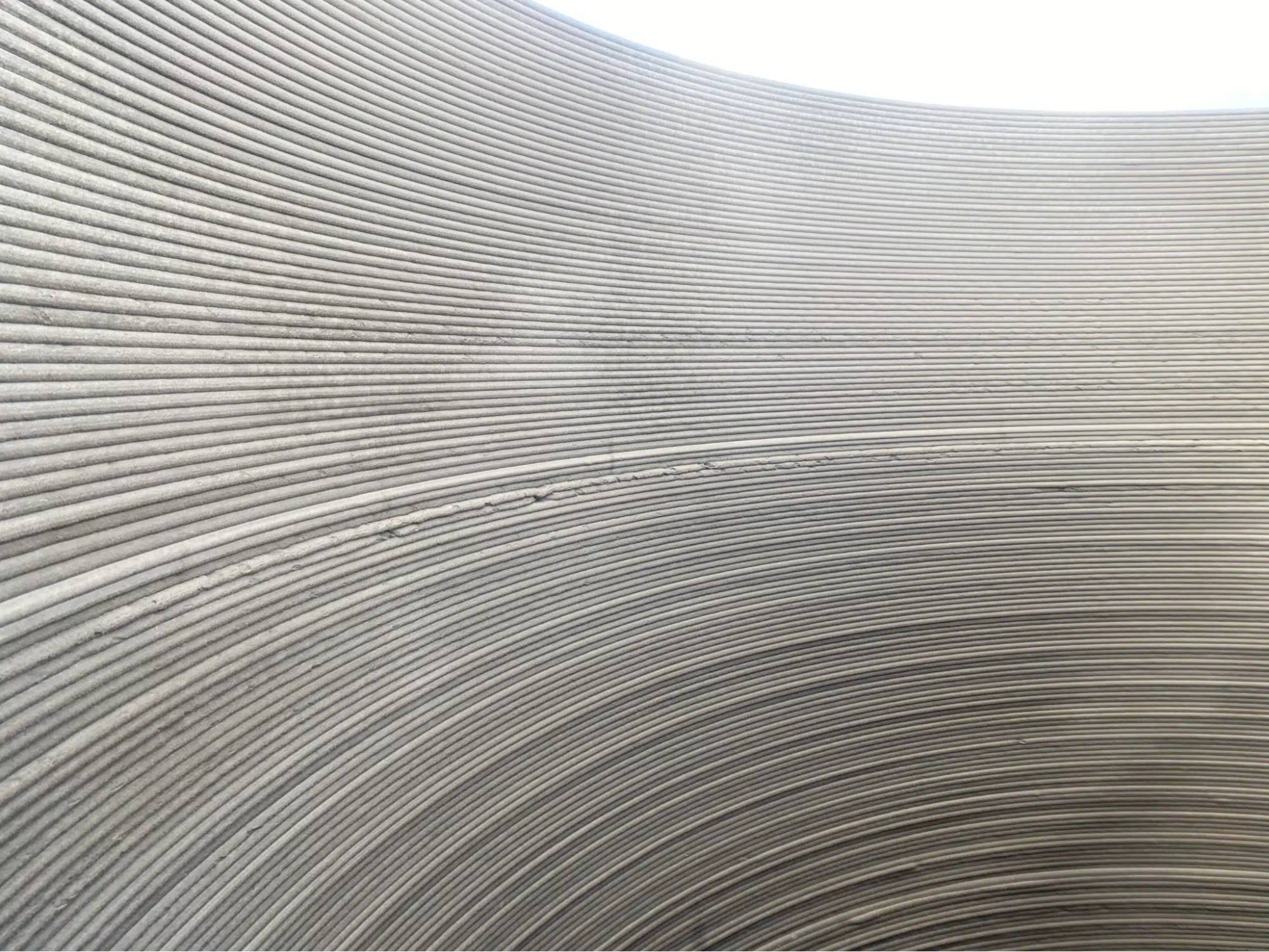

The development trade has lengthy grappled with environmental considerations, with conventional concrete manufacturing contributing to eight% of world greenhouse gasoline emissions. Nonetheless, 3D concrete printing expertise has confirmed to have a decrease carbon footprint as a consequence of lowered materials utilization and waste manufacturing. Corporations like CyBe Development, the producer of Hive3D Builders’ printers, have already pioneered eco-friendly constructing supplies with as much as 32% fewer CO2 emissions.

Carbon-Impartial

Hive3D Builders has taken the manufacturing of eco-friendly constructing supplies to the following degree by collaborating with Eco Supplies and Inexperienced Cement. They’ve developed a low-cost geopolymer cement alternative that boasts a powerful 93% discount in CO2 emissions. Geopolymers are sustainable constructing supplies that require much less vitality and produce fewer carbon dioxide emissions than conventional cement. By combining this carbon-neutral materials with 3D concrete printing, Hive3D Builders has unlocked great potential for lowering carbon emissions within the development course of.

Along with its environmental advantages, the carbon-neutral materials presents superior power and sturdiness. The geopolymer’s fascinating properties, similar to wonderful power, excessive sturdiness, and excellent fireplace resistance, contribute to the fabric’s spectacular efficiency. This enhanced adhesion makes it a horny various to conventional cement, enabling the development of extra resilient buildings.

Decrease Prices

Whereas 3D concrete printing supplies usually have increased prices in comparison with common concrete, Hive3D Builders has developed a singular system to decrease materials prices. By robotically mixing the cement alternative on-site with domestically sourced aggregates, they’ve managed to cut back the worth of their printing mortar to a 3rd of commercially obtainable choices. This value benefit might encourage hesitant development corporations to undertake 3D concrete printing as a less expensive, quicker, and extra sustainable various to conventional strategies.

The reluctance of development corporations to undertake new constructing applied sciences has hindered the widespread adoption of 3D concrete printing. Whereas 3D printing does permit discount in labor prices, the worth of supplies has nonetheless been off placing. Nonetheless, with Hive3D Builders’ low-cost, carbon-neutral materials and its confirmed sustainability and superior power, the development trade might lastly be persuaded to embrace additive manufacturing.

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t neglect to join our weekly additive manufacturing publication to get all the newest tales delivered proper to your inbox.