Direct air seize is slowly getting off the bottom, with crops up and working in Iceland, Switzerland, the US, and Canada. A lot of the carbon these amenities seize is both became a strong and saved underground or reused to fabricate varied chemical substances and industrial merchandise. Now a startup known as Twelve is planning to make use of captured CO2 to make jet gasoline.

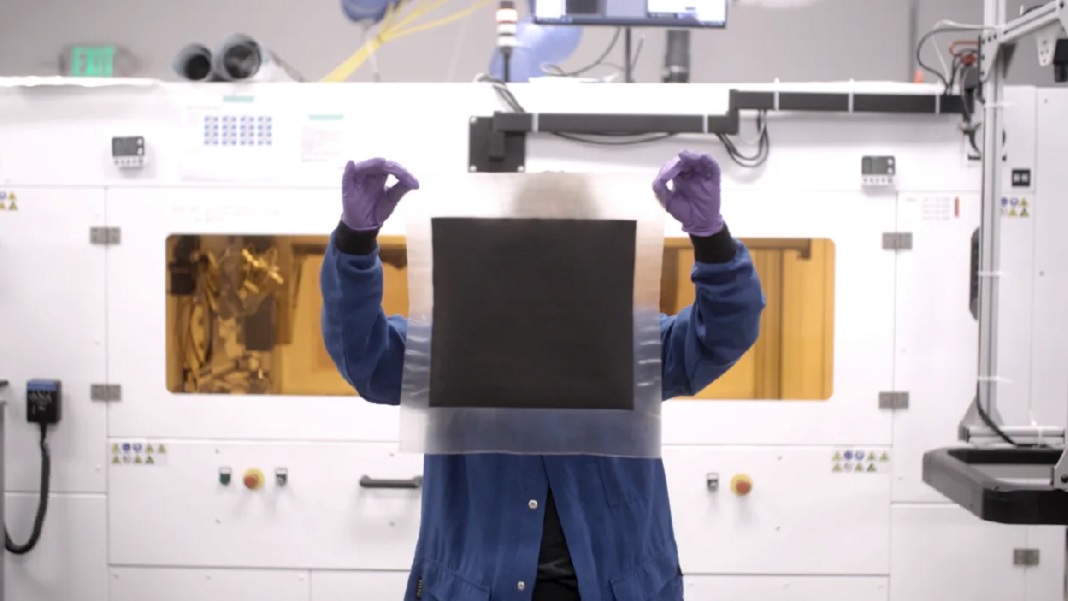

The corporate named their carbon conversion platform Opus. The system is modular and will be applied in present provide chains, taking CO2 from virtually any supply. The method makes use of electrolysis to separate the carbon and oxygen, then recombines the carbon with hydrogen to create gasoline. The CO2 shall be sourced from close by ethanol crops, pulp and paper mills, and waste processing amenities.

The US Air Drive examined the gasoline to make sure it may be safely used with out altering present aircraft engines. Changing half of a aircraft’s common gasoline with CO2-derived gasoline may end up in 90 % fewer lifecycle emissions. Alaska Airways has already agreed to purchase gasoline from Twelve.

Twelve broke floor on its manufacturing facility in Washington state earlier this month. The geographic alternative was as a consequence of a number of elements. For one, Seattle has lengthy been a hub for aerospace innovation; SpaceX, Blue Origin, Boeing, AeroTEC, and others all have operations there. Washington additionally has tax incentives for sustainable aviation gasoline. And two-thirds of the state’s electrical energy is generated by hydropower, giving it one of many highest percentages of unpolluted vitality within the nation.

The ability will initially produce round 40,000 gallons of gasoline a 12 months, finally scaling as much as 1,000,000 gallons a 12 months. That’s a drop in an Olympic-sized swimming pool when taken within the context of complete consumption, which reached an all-time excessive of 95 billion gallons in 2019.

So what are the limitations to considerably scaling up manufacturing? There’s loads of CO2 within the environment that wants capturing (greater than we’d ever be capable of seize and retailer in 100 years, as a matter of reality), and loads of demand for jet gasoline. Demand for this particular jet gasoline may find yourself being extra-high if its value reaches parity with typical gasoline (it will likely be dearer for some time), as a result of it might enable airways that use it to cut back their carbon footprint.

Customers have already turn out to be extra brand-conscious, when attainable shopping for services from corporations that mirror their values. This development is more likely to proceed sooner or later, and conservationism will hopefully solely turn out to be increasingly more extremely valued amongst extra individuals.

The most important determinant of which airline flyers select will doubtless nonetheless be value, as a result of let’s be sincere, all of us like an affordable flight. But when the worth for a given flight on two completely different airways is comparable, customers would really feel good selecting the extra planet-friendly choice.

The massive problem for the time being, although, is that capturing atmospheric carbon remains to be very expensive and energy-intensive. Many direct air seize crops are in-built areas which have entry to low-cost, plentiful geothermal vitality—like south-western Iceland’s Hellisheiði Energy Station.

For DAC to make financial and environmental sense, the method will both need to get extra energy-efficient, or vitality must get cheaper—inexperienced vitality particularly, because it wouldn’t make a lot sense to, say, construct a coal-fired energy plant to offer electrical energy for a facility utilizing big followers to filter carbon out of the air.

Regardless of these limitations, Twelve’s VP of challenge improvement Andrew Stevenson is optimistic. “Our purpose is to de-risk the know-how and the method—to function efficiently at a bigger scale,” he informed Forbes. “We need to scale up and construct different amenities worldwide.”

Development of the Washington plant is underway, with the ability anticipated to turn out to be operational in 2024.

Picture Credit score: Twelve