Researchers at Empa’s Cellulose & Wooden Supplies laboratory in Dübendorf Switzerland have achieved a serious breakthrough by growing a exceptional materials that possesses the power to be 3D printed, reveals biodegradability, modifications coloration, and conducts electrical energy. By combining cellulose and carbon nanotubes, the staff has unlocked new alternatives for sustainable sensors and shows.

The scientists started their experiment with hydroxypropyl cellulose (HPC), a generally used substance in prescription drugs and meals gadgets, which types liquid crystals when combined with water. These liquid crystals possess structural coloring, a phenomenon noticed in nature with examples like peacock feathers and butterfly wings. To regulate the colour change, the researchers launched carbon nanotubes to the HPC-water combination, enabling electrical conductivity and regulation of the liquid crystals’ coloration by means of voltage software.

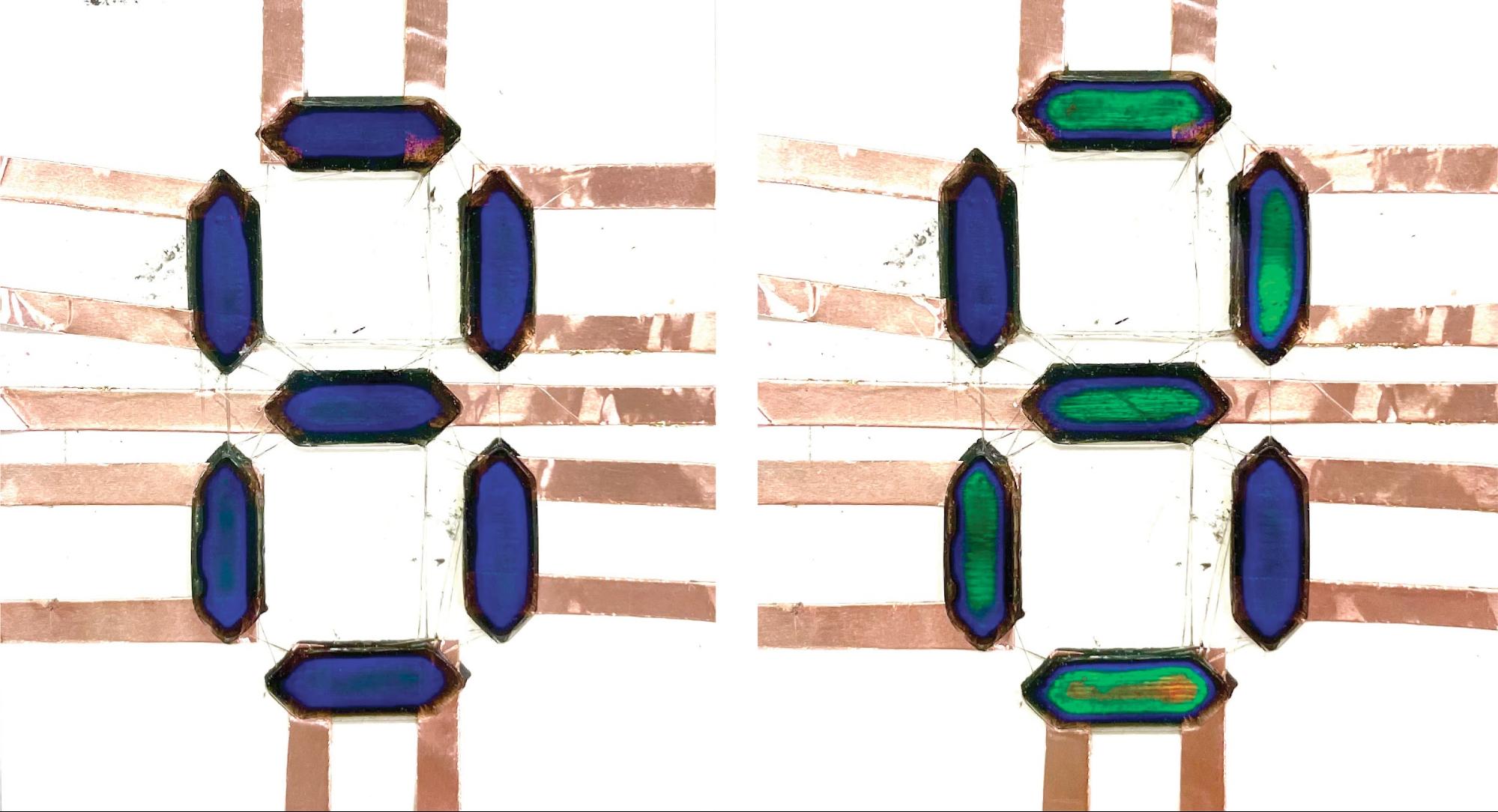

To make sure the fabric’s compatibility with 3D printing know-how whereas preserving its structural coloring and electrical conductivity, the researchers included cellulose nanofibers into the combination. This breakthrough has paved the way in which for the creation of biodegradable electronics, together with pressure sensors that alter their coloration in response to mechanical deformation and primary seven-segment shows.

Xavier Aeby, a co-author of the examine, expressed enthusiasm in regards to the potential functions of this cellulose-based ink, envisioning its use in meals high quality management and biomedical diagnostics. Pushed by their fascination with the era of structural coloring and its response to completely different environmental situations and components, the staff goals to delve additional into this line of analysis.

The event of sustainable and 3D-printable supplies holds immense promise for biodegradable electronics and the increasing realm of the Web of Issues. With continued exploration, Empa’s researchers attempt to uncover new charming phenomena and uncover further potential functions for this groundbreaking know-how.

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t overlook to join our weekly additive manufacturing e-newsletter to get all the most recent tales delivered proper to your inbox.