Nominations are actually open for the 3D Printing Trade Awards 2023. Who’re the leaders in 3D printing? Discover out on November thirtieth when the winners throughout twenty classes shall be introduced throughout a London-based dwell awards ceremony.

International shopper electronics firm Apple Inc. is reportedly utilizing metallic 3D printing expertise from Chinese language 3D printer producers Farsoon Applied sciences and Vivid Laser Applied sciences (BLT) to provide key parts for its new smartwatches.

Current experiences point out that the US-based expertise big is actively adopting 3D printing expertise, with the corporate stated to be testing the usage of binder jet methods for the manufacturing of stainless-steel chassis for its upcoming Apple Watch merchandise.

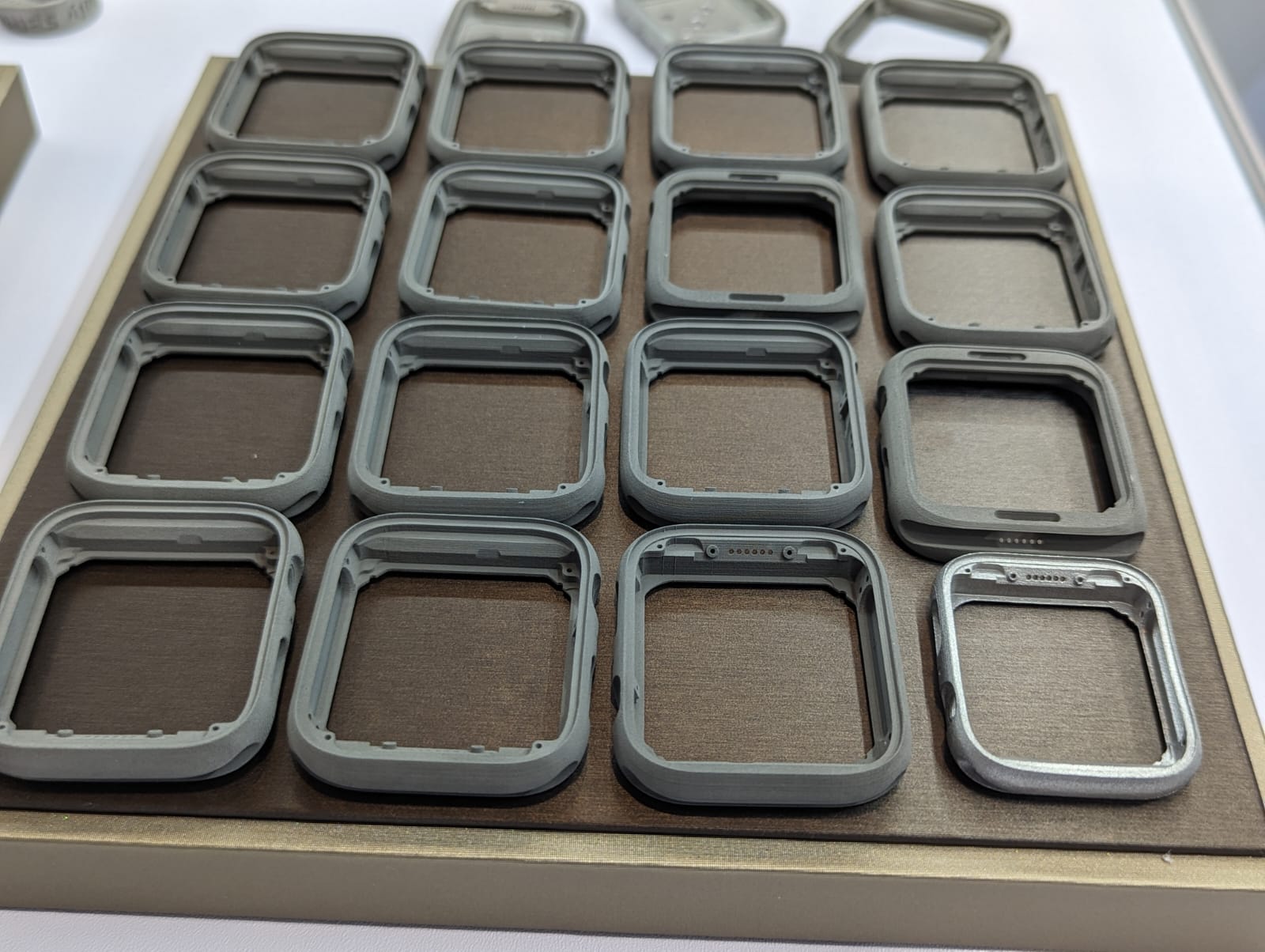

Furthermore, throughout Formnext + PM South China 2023, China-based binder jet 3D printer producer EasyMFG demonstrated smartwatch casings 3D printed in 316L stainless-steel utilizing its binder jetting expertise. This serves to additional spotlight the rising adoption of metallic 3D printing for the manufacturing of smartwatches.

The implications of those developments may very well be vital for the 3D printing trade, doubtlessly accelerating the usage of additive manufacturing for serial and mass manufacturing of shopper items.

3D printing Apple Watches

Historically, Apple has employed typical manufacturing strategies to provide its stainless-steel watches, which make up roughly 10% of the product line’s complete items. The corporate makes use of forging to transform bricks of fabric into smaller metallic blocks nearer to the machine’s dimension. CNC machining is then used to create the precise design of the watch casing.

Again in July, TF Worldwide Securities analyst Ming Chi-Kuo reported that Apple is actively adopting 3D printing expertise. On the time, Chi-Kuo outlined his expectation that a few of the titanium mechanical elements of the brand new Apple Watch Extremely shall be manufactured utilizing metallic 3D printing. In accordance with Chi-Kuo, Farsoon and BLT are supplying the 3D printers, whereas industrial laser methods specialist IPG Photonics is solely supplying the laser parts.

A latest Bloomberg publication has backed up these findings, pointing to the manufacturing of Apple Watch casings utilizing metallic 3D printing expertise. In accordance with the report, metallic binder jetting is getting used to 3D print the gadgets as near their precise dimension as doable, or their “close to internet form.” 3D printed in stainless-steel, the elements are then milled within the put up processing stage.

Apple is alleged to have been growing this system for the final three years, and has been testing the method with metal instances earmarked for the upcoming Apple Watch Sequence 9. It isn’t clear whether or not the primary shopper shipments of the brand new metal Apple Watches shall be 3D printed, however Apple reportedly has plans to use additive manufacturing for its titanium Extremely watch in 2024.

Regardless of these developments, 3D printing is anticipated to be reserved for lower-volume merchandise inside Apple’s manufacturing workflow. Certainly, most Apple Watch casings, in addition to different gadgets corresponding to Macs, iPads and a few iPhones, are made out of aluminum. Apple is but to make vital strides in 3D printing with aluminum, and is anticipated to focus its efforts on supplies corresponding to metal and titanium.

EasyMFG 3D printed smartwatch casings

Away from Apple, EasyMFG’s binder jetting expertise can also be being leveraged to fabricate smartwatch casings.

EasyMFG is predicated in Wuhan, China. Based in 2013 by a college professor, the corporate launched its first metallic binder jetting system in 2018. The present metallic 3D printer is EasyMFG’s third-generation system. The corporate has clients in Singapore, Hong Kong, India, Russia and Ukraine.

This week at Formnext South China in Shenzhen, the corporate has 316 stainless-steel 3D printed smartwatch instances on show. This metallic binder jetting course of requires a number of steps, 3D printing, debinding and sintering in a furnace. The 3D printed elements endure 18-20% shrinkage after they’ve been sintered, in response to EasyMFG.

The smartwatch elements are additionally doable in different supplies, together with titanium. Different alloys that may be 3D printed embody copper and tungsten.

The EasyMFG metallic binder jetting 3D printer is offered for simply over $100k.

EasyMFG says the client has not been disclosed.

Subscribe to the 3D Printing Trade e-newsletter to maintain updated with the most recent 3D printing information. You may also observe us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you curious about working within the additive manufacturing trade? Go to 3D Printing Jobs to view a number of obtainable roles and kickstart your profession.

Featured picture exhibits 3D printed smartwatch casings produced utilizing EasyMFG’s binder jetting system at Formnext + PM South China 2023. Picture by 3D Printing Trade.