Boston Micro Fabrication (BMF) has introduced it’s coming into the dental market with the launch of UltraThineer, the world’s thinnest beauty dental veneer in keeping with the corporate. The product has been developed in collaboration with Peking College in Beijing, China.

The brand new 3D printed veneers use projection micro stereolithography (PµSL), which manufactures veneers which might be thrice thinner than conventional veneers and require much less preparation for dental professionals in keeping with the corporate. The product is anticipated to be obtainable within the U.S. within the spring of 2024, following assessment by the U.S. Meals and Drug Administration (FDA).

BMF says it’s dedicated to growing functions the place its know-how can considerably scale back manufacturing time and price in addition to allow innovation. The veneers function a complicated materials, a manufacturing workflow, and a ending course of to ship thinner, extra comfy, and fewer invasive veneers in keeping with BMF.

“The flexibility to print ceramics at minimal thickness will likely be revolutionary. Our present processes for producing minimal prep veneers could be labour-intensive when in comparison with milled, full protection crowns in zirconia. Conservative discount of the affected person’s enamel ought to be practiced each time potential. I’m trying ahead to the beginning of this new know-how, permitting intricate, ultra-thin veneers to be printed. BMF’s developments and innovation will proceed to push the boundaries of dentistry and encourage innovation worldwide,” mentioned Jessica Love, Proprietor of Seize Dental Arts, a number one US supplier of beauty dental service.

Learn extra:

Boston Micro Fabrication secures $24m funding to enhance R&D and strengthen medtech collaborations

BMF unveils microArch S350, its highest throughput microscale 3D printer

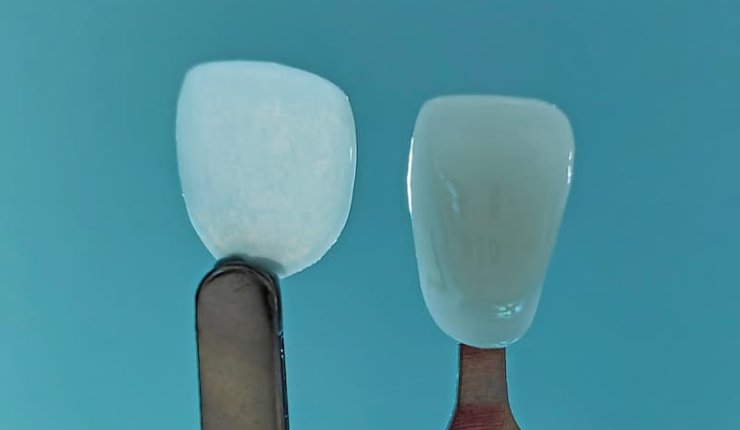

Based on BMF, veneers are at present manufactured to a thickness of roughly 0.5 mm or extra, and require ‘excessive’ prep work of current tooth, a extremely invasive, non-reversable and uncomfortable process for the affected person says the corporate.

BMF says that for aesthetic restoration, ultra-thin veneers enable little to no tooth preparation, preserving as a lot enamel as potential and are 100 µm (0.1mm) thick.

Professor Solar Yuchin, Peking College College of Stomatology mentioned: “The ultra-thin and robust 3D printed zirconia veneer know-how can shortly and painlessly strengthen and shield the floor of tooth, forestall chilly acid simulation and put on, and considerably enhance look. Extra importantly, in comparison with typical ceramic veneer know-how, your complete strategy of tooth discount is eradicated.”

John Kawola, CEO-World, BMF added: “Utilizing our distinctive know-how, corporations throughout industries, from electronics to medical gadgets, are conserving tempo with the rising miniaturisation of know-how. Along with persevering with to companion with our prospects on their very own improvements, we’re excited to unveil one of many first developed functions of our know-how. We all know that sufferers and dentists alike can profit from thinner veneers and are trying ahead to bringing increased ranges of precision to the beauty dental trade.”