Chromatic 3D Supplies has lately performed a pivotal position in enhancing the effectivity and reliability of Austria’s federal railway, ÖBB, via the set up of 3D printed alternative elements. ÖBB confronted important challenges in sourcing out of date elements, main them to hunt out Chromatic’s experience in additive manufacturing.

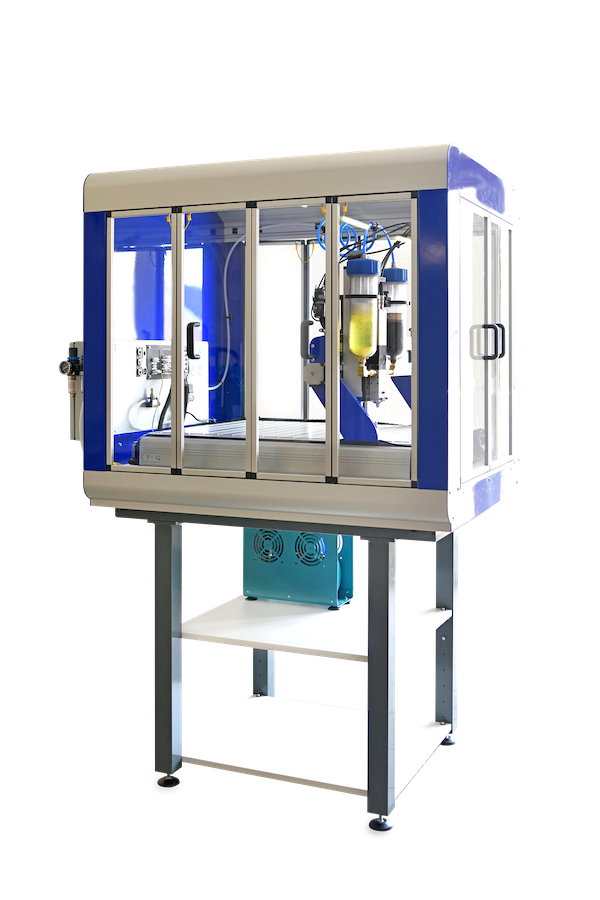

The collaboration resulted within the creation and set up of a wide range of essential elements, together with polyurethane bellows, grommets, cable glands, and valve covers. These elements have been meticulously crafted utilizing Chromatic’s cutting-edge RX-AM reactive extrusion additive manufacturing platform. Designed with precision, these 3D printed elements not solely increase the efficiency and longevity of ÖBB’s trains but in addition elevate passenger consolation.

One notable achievement is the discount of vibrations and the prevention of mud and moisture infiltration, guaranteeing the seamless operation of ÖBB’s railcars. These elements, constructed from thermoset polyurethane materials, should not solely sturdy but in addition extremely versatile, providing an ideal seal in opposition to air and water. The load-bearing grommets, boasting stable 1.5cm thick partitions, exemplify the innovation behind this undertaking.

Sebastian Otto, Head of AM at ÖBB Prepare Tech, praised Chromatic’s means to print polyurethane with various hardness ranges, making them the perfect companion for this enterprise. Dr. Bart Engeldahl, Managing Director of Chromatic 3D Supplies in Germany, emphasised the sturdiness and reliability of their 3D printed supplies.

This profitable partnership has far-reaching implications for industries past rail transportation, together with aerospace, industrial, and protection functions. Chromatic’s dedication to high quality is clear, as they lately introduced plans to scale up manufacturing of their RX-AM reactive extrusion additive platform following a considerable $3.1 million funding.

Supply: tctmagazine.com

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t neglect to join our weekly additive manufacturing e-newsletter to get all the most recent tales delivered proper to your inbox.