A brand new automated shutdown system that helps shield native watercourses has been put in by AUMA Actuators in a wash-down space for de-icing industrial airliners at a London airport.

The agency designed, put in, examined and deployed a brand new computerized shutdown system that stops a excessive focus of glycol from coming into the watercourse, within the occasion of a higher-than-normal degree within the plane wash-down combination.

Colin Borrows, Operations Supervisor, AUMA Actuators Restricted, stated: “This was a very fascinating and technically difficult challenge, which had at its coronary heart the integrity of the native watercourse.

“A pair of manually managed penstocks was already put in in an underground valve chamber with severely restricted house. Our specialist confined house crew was tasked with automating the management of the penstocks, while retaining the choice to manually management the penstocks within the occasion of {an electrical} failure. We achieved this utilizing AUMA’s handwheel extension drive to permit valve key operation, alongside the flexibility to distant mount the management heads.”

The system contains 4 primary components; the actuators with remote-mounted AC management heads; the present penstocks; a bespoke management panel; and a glycol analyser.

It operates by opening and shutting two penstocks mounted beneath the airport apron, which diverts wash-down water to an interceptor holding tank in a managed sequence triggered by a glycol analyser. The analyser continuously displays the glycol water combine. When excessive glycol focus is detected, a sign is shipped to the management panel, which initiates the shutdown sequence to the actuators.

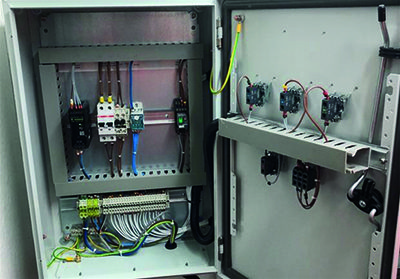

AUMA technicians constructed a customized panel to regulate the actuators, in keeping with the glycol pattern station. Two AUMA SA07.6 (actuators), AC01.2 (controls) and GK10.2 (gearbox) actuators and gearbox mixtures have been put in within the underground valve chamber, with cable set run to the airport’s kiosk, plus mounting of management heads.

Area technicians eliminated the outdated gearboxes, driveshafts and mechanically put in the alternative gearboxes and actuators. The cable units have been then run within the cable ducting and fed into the kiosk. The management panel, native isolators and management heads have been mounted and linked within the kiosk. The SA kind actuator vary is for open-close responsibility and positioning responsibility and are rated for sophistication A and B or varieties of responsibility S2 – 15 min. A particular model for longer working is on the market for S2 – 30 min responsibility. Actuators may be mixed with numerous controls from easy OPEN-CLOSE controls to the micro-controlled variations with logging of working information or fieldbus interface.