A analysis group led by Prof. Zeng Jie from the College of Science and Know-how of China (USTC) of the Chinese language Academy of Sciences (CAS), has made a big breakthrough within the area of plastic upcycling.

Their examine, titled “Solvent- and Hydrogen-Free Catalytic Conversion of Excessive-Density Polyethylene Plastics,” introduces a novel dehydroaromatization and hydrogenolysis tandem technique for changing high-density polyethylene (HDPE) plastics into precious cyclic hydrocarbons with out the necessity for solvents or hydrogen. The findings have been revealed in Nature Nanotechnology.

Polyethylene, one of the vital generally used plastics, poses challenges when it comes to pure degradation because of its steady chemical construction. Recycling applied sciences for waste polyethylene plastics not solely mitigate air pollution but additionally supply financial advantages.

Drawing inspiration from two processes within the petroleum business, specifically catalytic reforming of short-chain gasoline fractions and hydrocracking of heavy oils, the analysis group sought to deal with waste HDPE plastics as a solid-petroleum uncooked materials by way of environmentally pleasant catalytic conversion, thereby producing downstream petroleum-based chemical merchandise.

Impressed by two processes within the petroleum business, the analysis group targeted on catalytic reforming of short-chain gasoline fractions to acquire higher-value cyclic hydrocarbons, which generates hydrogen, and the hydrocracking of heavy oils to supply short-chain hydrocarbons, which consumes hydrogen.

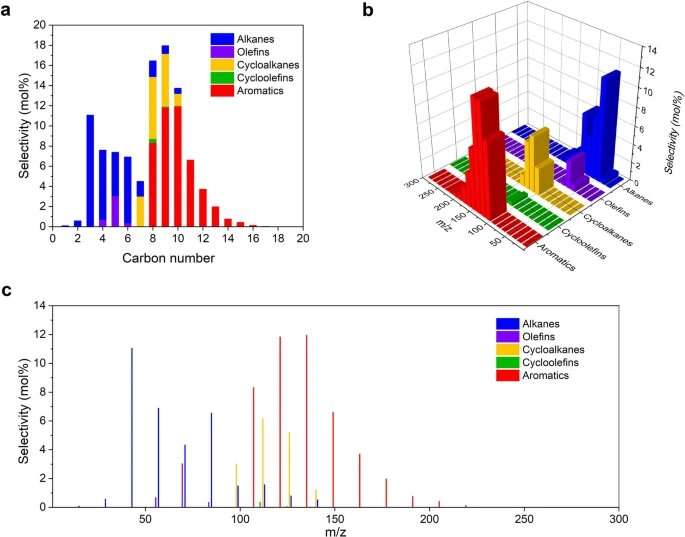

Constructing upon these processes, the analysis group devised a “hydrogen-breathing” technique for degrading high-density polyethylene (HDPE) plastics. They developed a molecular sieve-loaded metallic ruthenium catalyst (Ru/HZSM-5) that facilitates the dehydrogenation of the plastic into cyclic hydrocarbons, “breathe out” hydrogen within the course of. Concurrently, the plastic “breathe in” the launched hydrogen and undergoes cracking, remodeling into short-chain hydrocarbons.

The analysis group then explored the upcycling response pathways of high-density polyethylene plastics. They carried out catalytic experiments on the recycling of HDPE plastics with totally different molecular sieve loadings of ruthenium steel, and examined the impact of the molecular sieve pores on the response.

The outcomes present that the HZSM-5 molecular sieve has a reasonable pore dimension, which not solely avoids the formation of thick cyclic fragrant hydrocarbons and carbon deposits, but additionally ensures the graceful desorption of cyclic hydrocarbons, thus guaranteeing the continuity and stability of the catalytic response. Ru/HZSM-5 catalysts have an excellent cyclic stability, and are additionally appropriate for various kinds of polyethylene plastics.

This analysis represents a big development in plastic upcycling and holds nice promise for the sustainable improvement of our society. By offering an progressive answer for the conversion of HDPE plastics into precious cyclic hydrocarbons, this examine contributes to the continuing efforts to deal with plastic waste and promote a extra sustainable future.

Extra info:

Junjie Du et al, Environment friendly solvent- and hydrogen-free upcycling of high-density polyethylene into separable cyclic hydrocarbons, Nature Nanotechnology (2023). DOI: 10.1038/s41565-023-01429-9

Offered by

College of Science and Know-how of China

Quotation:

Crew develops solvent- and hydrogen-free methodology to upcycle high-density polyethylene plastics (2023, July 14)

retrieved 14 July 2023

from https://phys.org/information/2023-07-team-solvent-hydrogen-free-method-upcycle.html

This doc is topic to copyright. Other than any honest dealing for the aim of personal examine or analysis, no

half could also be reproduced with out the written permission. The content material is supplied for info functions solely.