JON HARPER | Onsemi

Grid energy is AC for a lot of good causes, but nearly each machine requires DC energy to function. Because of this AC-DC energy provides are used nearly all over the place, and, in a time of environmental consciousness and rising vitality prices, their effectivity is crucial to controlling working prices and utilizing vitality properly.

Merely put, effectivity is the ratio between enter energy and output energy. Nonetheless, the enter energy issue (PF) have to be thought-about – that is the ratio between helpful (true) energy and complete (obvious) energy in any AC-powered machine – together with energy provides.

With a purely resistive load, the PF will probably be 1.00 (‘unity’) however a reactive load will lower the PF because the obvious energy rises, resulting in diminished effectivity. A less-than-unity PF outcomes from out-of-phase voltage and present, a big harmonic content material, or a distorted present waveform – widespread in discontinuous digital masses akin to switched mode energy provides (SMPS).

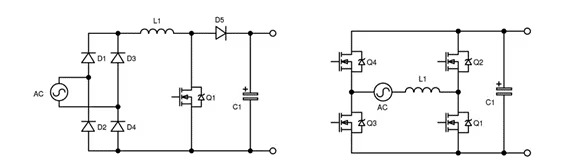

Given the influence on effectivity {that a} low PF has, when energy ranges are above 70W, laws requires designers to include circuitry that may right the PF to a worth near unity. Usually, energetic PF correction (PFC) employs a lift converter that converts rectified mains to a excessive DC degree. This rail is then regulated utilizing pulse width modulation (PWM) or different methods.

This strategy usually works and is easy to deploy. Nonetheless, fashionable effectivity necessities such because the difficult ‘80+ Titanium customary’ stipulate the effectivity throughout a large working energy vary, requiring peak efficiencies of 96% at half load. This implies the road rectification and PFC stage should obtain 98% as the next PWM DC-DC will lose an extra 2%. Attaining that is very difficult as a result of losses throughout the diodes within the bridge rectifier.

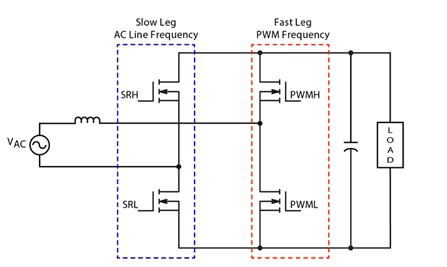

Changing the enhance diode with a synchronous rectifier helps and the 2 line rectifier diodes will be equally changed which additional enhances effectivity. This topology is known as totem pole PFC (TPPFC) and, in principle, with a super inductor and ideal switches, effectivity will strategy 100%. Whereas silicon MOSFETs provide good efficiency, vast bandgap (WBG) units provide far nearer to ‘ideally suited’ efficiency.

As designers improve frequency to scale back the dimensions of magnetic elements, dynamic losses in switching units may also improve. As these losses will be vital with silicon MOSFETs, designers are turning to WBG supplies together with silicon carbide (SiC) and gallium nitride (GaN) – particularly for TPPFC functions.

Important conduction mode (CrM) is usually the popular strategy for TPPFC designs at energy ranges up to some hundred watts, balancing effectivity and EMI efficiency. In kilowatt designs, steady conduction mode (CCM) additional reduces RMS present inside switches, lowering conduction loss.

Even CrM, can see an effectivity drop approaching 10% at gentle masses which is a roadblock to attaining ‘Titanium 80 Plus’. Clamping (‘folding-back’) the utmost frequency forces the circuit into DCM at gentle masses, thereby considerably lowering peak currents.

With 4 energetic units to be pushed synchronously and the necessity to detect the inductor’s zero present crossing to pressure CrM, TPPFC design will be removed from trivial. Moreover, the circuit should swap in / out of DCM whereas sustaining a high-power issue and producing a PWM sign to manage the output – in addition to offering circuit safety (akin to over present and over voltage).

The plain strategy to deal with these complexities is to deploy a microcontroller (MCU) for the management algorithms. Nonetheless, this requires the technology and debugging of code, which add vital effort and threat to the design.

Nonetheless, time-consuming coding will be averted by utilizing a completely built-in TPPFC management resolution. These units provide a number of benefits together with excessive efficiency, quicker design time and diminished design threat as they eradicate the necessity to implement a MCU and related code.

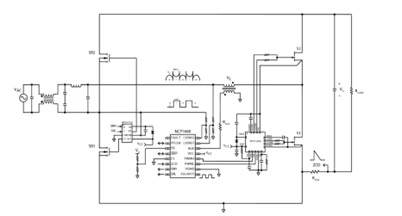

A superb instance of the sort of machine is onsemi’s NCP1680 mixed-signal TPPFC controller that operates in fixed on-time CrM, thereby delivering glorious effectivity throughout a large load vary. The built-in machine options ‘valley switching’ throughout frequency foldback at gentle masses to reinforce effectivity by switching at a voltage minimal. The digital voltage management loop is internally compensated to optimize efficiency all through the load vary, whereas guaranteeing that the design course of stays easy.

The progressive TPPFC controller features a novel low-loss strategy for present sensing and cycle-by-cycle present limiting gives substantial safety with out the necessity for an exterior Corridor-effect sensor, thereby lowering complexity, measurement and value.

A full suite of management algorithms is embedded throughout the IC, giving designers a low-risk, tried-and-tested resolution that delivers excessive efficiency at an economical value level.