Developed by Creality, the Ender-5 S1 is a midrange FFF 3D printer with an upgraded movement system and a variety of premium options. Be a part of us as we assessment the primary advantages of the Ender-5 S1, our expertise, testing outcomes, and what to anticipate from this 3D printer.

Creality is a expertise firm primarily based in Shenzhen, China, and was established in 2014. It has since developed a big 3D printing portfolio, with the Ender sequence being its most well-known.

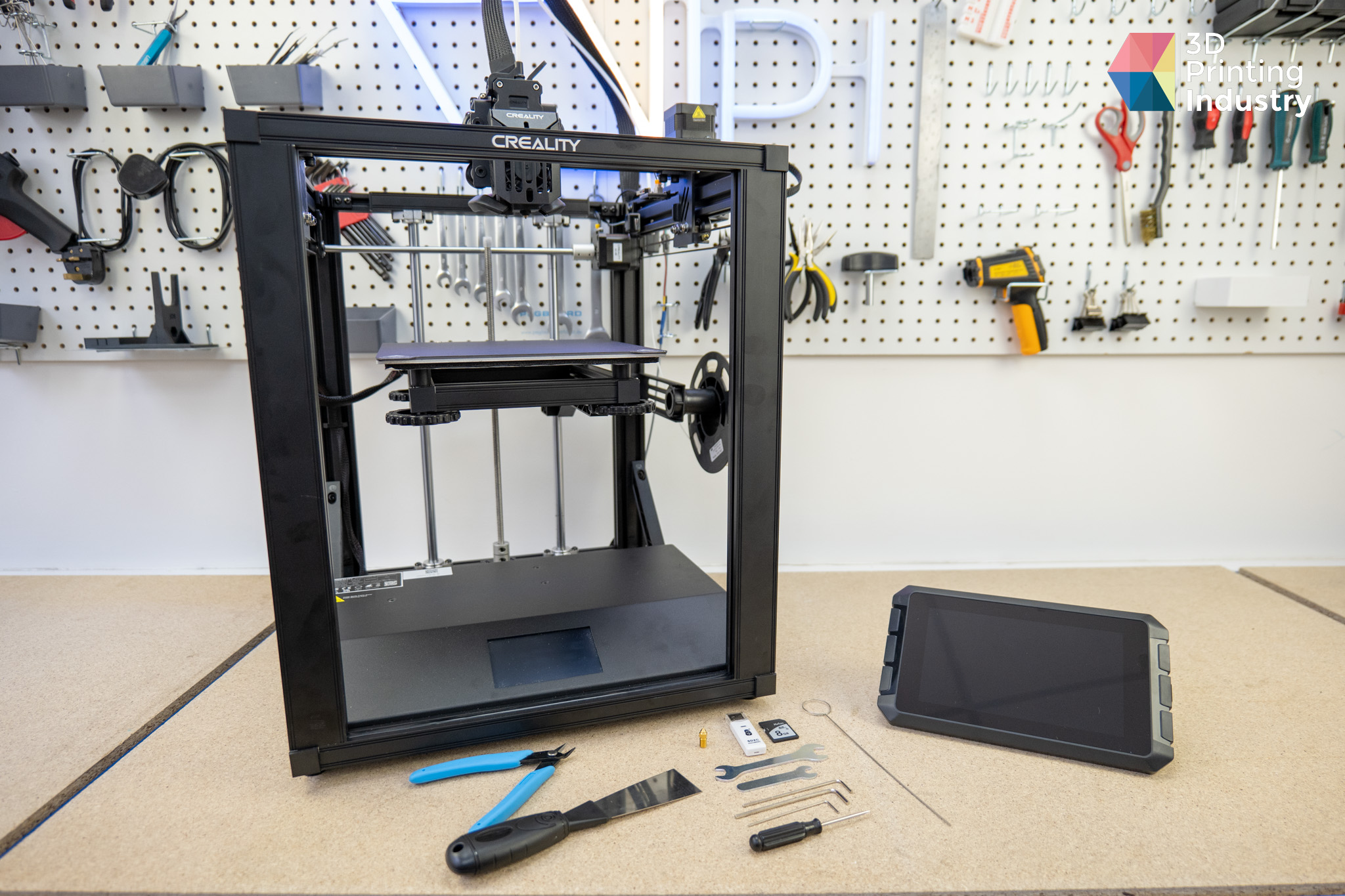

The Ender-5 S1 comes properly packaged with form-fitting foam sheets to guard the components. Our 3D printer arrived intact with no broken or lacking parts.

Packaging and Unboxing of the Ender-5 S1. Photographs by 3D Printing Trade.

Meeting of the 3D printer is simple, as is the set-up, with just a few steps required. It took us about 40 minutes from opening the field to start out 3D printing.

Essential Advantages of the Ender-5 S1

In line with Creality, the Ender-5 S1 has three principal promoting factors that make it an awesome alternative for 3D printing fanatics. First, it saves you time by permitting you to 3D print sooner with minimal loss in high quality, due to its upgraded movement system and cooling system. Second, it provides you extra artistic freedom by enabling you to 3D print a variety of supplies, from versatile to excessive temperature, resulting from its upgraded extruder and direct drive system. Third, it makes the 3D printing course of simpler by offering you with numerous quality-of-life options and upgrades, resembling auto mattress leveling, contact display, runout sensor, and extra.

Excessive output at good high quality

One of the crucial noticeable benefits of the Ender-5 S1 is its pace. It has a secure dice body with further reinforcement, which reduces vibrations and improves stability. It comes with an upgraded cartesian movement system that permits for greater speeds and accelerations, leading to shorter 3D printing occasions whereas retaining a very good degree of high quality.

The 3D printer additionally has a robust 5015 fan and a custom-made cooling duct referred to as the “Urus”, which improves cooling effectivity. This mixture is designed to supply uniform airflow enabling constant high quality and accuracy.

Materials Compatibility

The Ender-5 S1 can 3D print versatile and high-temperature supplies due to its direct drive extruder referred to as the “Sprite,” which is dependable for 3D printing supplies resembling TPU. It additionally has an all-metal sizzling finish, which may attain as much as 300°C. This permits 3D printing of higher-performance supplies resembling ABS (with non-compulsory enclosure), PC, ASA, and HIPS, which want greater temperatures than PLA. The new finish heats as much as 200°C in 1 minute and 15 seconds and as much as 300°C in 2 minutes 35 seconds.

Extruder meeting. Photographs by 3D Printing Trade.

The 3D printer additionally has a heated mattress, reaching as much as 100°C. This helps with adhesion and prevents warping. The printbed heats as much as 60°C in 3 minutes and 10 seconds and as much as 100°C in 9 minutes and 30 seconds.

Included Premium Upgrades and High quality of Life Options

The Ender-5 S1 additionally has numerous options and upgrades that make the 3D printing expertise extra handy and fulfilling. These are normally present in premium 3D printers and are unusual on this worth vary.

Considered one of them is the textured spring metal PC sheet, which attaches to the magnetic mattress. The sheet offers good adhesion for 3D prints however permits straightforward elimination by bending it barely.

One other quality-of-life characteristic is the filament runout sensor, which detects when the filament is about to expire. The sensor pauses the 3D print and alerts the consumer, permitting them to vary filament with out shedding progress, which we now have examined. The sensor works as marketed, and the 3D print resumes from the place it has stopped.

Print mattress and filament runout sensor. Photographs by 3D Printing Trade.

The Ender-5 S1 has an auto mattress leveling system, which makes use of a BLTouch probe to measure the gap between the nozzle and the mattress at 16 factors. The system adjusts for any unevenness or tilt of the mattress, guaranteeing a degree floor for 3D printing.

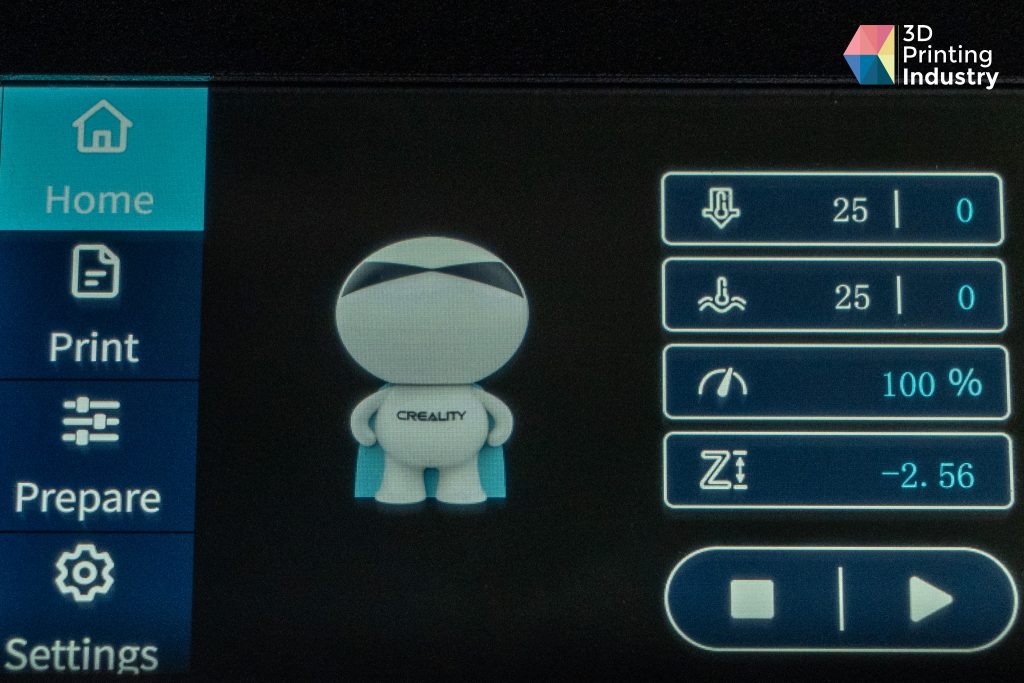

As well as, it has a contact display with an intuitive UI, which makes it straightforward to navigate via menus and settings. The display additionally permits the consumer to regulate some parameters mid-print, resembling pace, temperature, z-offset, and so on.

The Ender-5 S1 comes with its personal slicer referred to as Creality Slicer, which relies on Cura. It comes with a variety of ready profiles for the 3D printer, which work properly sufficient. In our testing, we’ve in contrast each Cura and Creality Slicer, and there wasn’t any noticeable distinction within the 3D print high quality, however Cura does have extra up-to-date settings and options in comparison with the Creality Slicer.

Benchmarking

At 3D Printing Trade, we take a look at 3D printers comprehensively to find out their strengths and weaknesses. To do that, we acquire knowledge on the accuracy of the 3D printer, precision, repeatability, and efficiency on bridging, overhangs, towers, width, and retraction. After this, we 3D print numerous fashions and supplies to check typical functions.

To begin, we 3D print a Benchy to measure and evaluate the size of varied options such because the chimney, cargo field, and entrance window to the unique mannequin to check the accuracy of the machine. The typical dimension deviation between the reference and the 3D printed mannequin is 0.09mm, which is an excellent consequence, as the common for many different 3D printers for this take a look at is 0.15mm.

3D printed Benchy and a desk of dimensional measurements of the 3D print. Photograph and desk by 3D Printing Trade.

We then carried out a sequence of repeatability assessments for 3 totally different components (Sq., hexagon, and tube shapes), which had been 3D printed 12 occasions, measured, and in comparison with the unique half dimensions. For a profitable consequence, the measured dimensions ought to have a median deviation of lower than 0.1mm and a regular deviation of beneath 0.05mm.

Repeatability assessments. Photographs by 3D Printing Trade.

On this sequence of assessments, dimensional accuracy was decrease than the goal of 0.1mm, with the common deviation coming in at 0.15mm, however it was pretty constant, with the common customary deviation being 0.03mm. This could indicate that the 3D printer is over-extruding, and to realize dimensional accuracy, one must tune settings resembling Circulation Fee and Gap Horizontal Growth within the slicer. If one will not be in search of good dimensional accuracy with out tuning, the Ender-5 S1 3D prints fairly properly out of the field.

Histogram graphs and dice measurements desk. Pictures by 3D Printing Trade.

Following this, we 3D printed a tower and a mattress width take a look at to find out the utmost 3D print dimensions, as they don’t all the time match up to what’s acknowledged by the producer. Our outcomes present that the precise 3D print dimensions are fairly shut to what’s marketed, with the usable peak being 279mm out of 280mm and the width being 218x218mm out of 220x220mm. We observed that within the tower take a look at, the highest third of the tower will get progressively worse because it will get greater. This appears to be as a result of wobble of the cantilevered construct plate, which is barely supported on one aspect; as such, customers needs to be aware of this when 3D printing tall fashions with small bases.

Bridge, overhang, tower, width, and stringing assessments. Photographs by 3D Printing Trade.

Subsequent, we examined how properly the Ender-5 S1 handles bridges and overhangs. We 3D print these in each the X and Y axis to see if there may be any discrepancy. The bridging take a look at 3D printed properly, sustaining good high quality as much as 25 mm in each X and Y; that is fairly good as the common is normally round 15mm. The 3D printer carried out fairly properly for the overhang take a look at 3D printed within the X-axis going as much as 60°, however the Y-axis one solely managed to take care of good high quality as much as 55°. This efficiency is barely above common, which is 55° for different 3D printers.

The 3D printer carried out very properly on the stringing take a look at, giving us a really clear 3D print. This is because of its high-quality direct drive system and cooling. This take a look at reveals that the Ender-5 S1 handles retraction very properly.

We’ve additionally examined round trajectory to see how good of a circle this 3D printer can produce. It’s common for 3D printers to be off in a single axis, making circles nearer to an oval. On this case, the Ender-5 S1 carried out nice, with all three 3D prints having constant measurements in each X and Y axes with the deviation under 0.1mm.

Round trajectory 3D prints and knowledge desk. Photographs and desk by 3D Printing Trade.

To check high quality tolerances and accuracy of the 3D printer, we 3D print a set of nuts and bolts and a planetary gear. Each of those 3D prints require excellent 3D print accuracy to maneuver freely after being 3D printed.

Small precision take a look at and planetary gear. Photographs by 3D Printing Trade.

The Ender-5 S1 didn’t disappoint us and has produced the nuts and bolts and the planetary gear that transfer easily with out issues and no post-processing, indicating good 3D print accuracy.

Velocity assessments

We 3D printed a sequence of fashions to check the influence of 3D printing pace on high quality and time. We used the Benchy as our mannequin, which has numerous geometric options that problem any 3D printer. This additionally allowed us to check the speed-quality trade-off.

Velocity assessments. Photographs by 3D Printing Trade.

We began with a sluggish pace as a baseline which is equal to a regular FFF 3D printer, which took 70 minutes to finish. Then we elevated the acceleration to 2000mm/s2, which is the marketed restrict of the Ender-5 S1. This diminished the 3D print time by virtually 30% to 50 minutes with out compromising high quality.

Subsequent, we elevated the 3D printing pace to 120mm/s whereas retaining acceleration fixed. This additional diminished 3D print time however on the expense of high quality. We observed cooling points with overhangs and under-extrusion in some areas. The quickest Benchy we 3D printed took 40 minutes however had poor high quality. This can be acceptable for some customers, however they need to know this trade-off between pace and high quality earlier than shopping for.

3DPI Benchmark

We additionally 3D printed the 3D Printing Trade’s personal benchmark mannequin, which mixes a lot of our smaller assessments into one half. We used this mannequin to guage the efficiency of the Ender-5 S1 primarily based on our standards.

3DPI benchmark in PLA and radar chart. Photographs and charts by 3D Printing Trade.

The Ender-5 S1 carried out very properly on this benchmark, aside from the overhang assessments. We noticed constant failures of the overhangs that went from 45° to 60° on this specific mannequin, as they curled up and bought caught by the nozzle. This resulted in them being ripped off the remainder of the 3D print.

In different areas, the Ender-5 S1 carried out very properly. It has efficiently 3D printed very skinny partitions in each X and Y. Within the tolerance take a look at, we might take out all of the cylinders as much as 0.2mm, which is a formidable consequence. There isn’t any seen ghosting current on the 3D print, which one would possibly anticipate when 3D printing at excessive speeds. There may be minimal stringing displaying that retraction works fairly properly on this 3D printer.

Total, the Ender-5 S1 scored 84/100, which is superb. high quality 3D printer normally has a rating of 60+.

Functions and materials assessments

Lastly, we 3D printed a choice of fashions utilizing totally different supplies to see how the 3D printer would deal with them in numerous use-case conditions with a variety of supplies.

PLA

We selected the Salty McCreedy bust by Ben Dansie to check how the 3D printer will deal with a big, detailed 3D print that will take over 48 hours to finish. The mannequin has a variety of texture, doesn’t require helps, and was scaled to 220 mm in peak.

Salty McCreedy in PLA. Photographs by 3D Printing Trade.

The bust got here out nice. The Ender-5 S1 accomplished this lengthy 3D print with out failures or any main defects. This demonstrates how reliable this machine is on longer-running 3D prints, making it an awesome alternative for hobbyists and prop makers.

TPU

Subsequent, We challenged the 3D printer with a TPU 3D print; we selected a card pockets that 3D prints upright with gyroid infill to essentially problem the Ender-5 S1. Versatile filaments are tough to 3D print and provides most customers a variety of bother, so we wished to see if Creality’s “Sprite” extruder might deal with it.

TPU pockets. Photographs by 3D Printing Trade.

The pockets was 3D printed efficiently. It caught to the construct plate a little bit too properly, leaving a few of the first layer on it, however apart from that, there have been no defects or layer shifts. Adhesion between layers can be very robust, making this half solely purposeful. We take into account the Ender-5 S1 to be able to 3D printing versatile filaments with ease.

Polycarbonate / PC

We then used the Ender-5 S1’s all-metal sizzling finish to 3D print a purposeful half out of Polycarbonate, a cloth that requires greater temperatures to 3D print. The all-metal sizzling finish permits customers to 3D print with greater temperature filaments, extra suited to engineering and prototyping makes use of. For this take a look at, we selected a geared hinge that requires high quality tolerances and excessive power. If the 3D printer is inaccurate, the half can simply fuse or be very stiff when shifting.

Polycarbonate print in place gear hinge. Photographs by 3D Printing Trade.

The gear hinge 3D printed very properly and moved freely after 3D printing with little to no wobble. We had to make use of a brim and nonetheless had some minor warping on the backside, however nothing that affected the mechanism. This reveals that the 3D printer can deal with high-temperature, high-strength supplies appropriate for mechanical components and prototyping.

PETG

We additionally 3D printed a big piece of tetrahedron chain mail with PETG, a well-liked different to PLA. This was a very good take a look at for the 3D printer’s retraction and cooling skills, as PETG 3D prints at a better temperature, and the mannequin has many small bridges. The components had been additionally skinny and wanted a stronger materials than PLA to be purposeful. PETG is infamous for stringing as properly, so this take a look at will showcase the retraction capabilities of the Ender-5 S1.

PETG Tetrahedron mail. Photographs by 3D Printing Trade.

This 3D print was difficult, because it required a wonderfully flat mattress floor, which is tough to realize for many 3D printers. We had to make use of a raft to 3D print it efficiently, however the last consequence was excellent. We additionally examined the filament runout sensor on this 3D print, swapping to a different coloration filament mid-way. The Ender-5 S1 carried out this simply; the 3D printer paused, saved the progress, and allowed us to switch filament and resume the 3D print easily; spectacular on a posh 3D print with so many particular person components.

Our Expertise

Our expertise with the Ender-5 S1 is usually constructive, however a couple of areas might be improved.

The packaging of the 3D printer is sturdy, and the components are well-protected with form-fitting foam sheets. The 3D printer arrived in good situation, with no seen harm or lacking components.

The 3D printer is simple to assemble and arrange, requiring just a few steps. It is available in three pre-assembled items with clear directions and instruments. The wiring can be easy and labeled. The entire course of took us about 40 minutes.

The machine is able to 3D print after the preliminary setup. The touchscreen is helpful for beginning and controlling the 3D printer, however it beeps loudly each time it’s touched, and there’s no choice to show it off.

An odd quirk that we observed is that the mattress and nozzle warmth up individually when beginning a 3D print, which takes about 5 minutes to achieve 60°C and 200°C. Nevertheless, if we use the preheating choice earlier than beginning a 3D print, they warmth up collectively and attain the goal temperature in 3 minutes.

After the primary few 3D prints, the POM wheels began to indicate indicators of wear and tear which progressed in a short time. Whereas this didn’t influence our 3D printing, the issue persevered even after adjusting them following directions.

The PC textured spring metal sheet offers excellent first-layer adhesion and has handy grooves to assist align it with the print mattress. Nevertheless, the PC floor is simple to wreck when eradicating some 3D prints and when 3D printing at excessive temperatures resembling 250°C+ for the recent finish and 70°C+ for the print mattress.

The Ender-5 S1 works fairly properly out of the field. It has the potential to carry out even higher which may be unlocked by skilled customers via additional tweaking and fine-tuning.

Remaining Verdict

The Ender-5 S1 is a quick and versatile 3D printer that provides a variety of premium options and upgrades for an inexpensive worth. It’s appropriate for newbie and intermediate customers who’re in search of improved efficiency and quality-of-life options without having to do any modifications themselves.

Nevertheless, the 3D printer will not be good and has some drawbacks and limitations. Whereas it will possibly 3D print as quick as marketed and supply vital time financial savings, there’ll all the time be some lack of high quality because the pace goes up, which we consider is a trade-off any purchaser ought to concentrate on.

We suggest the Ender-5 S1 to customers who worth pace, comfort, and reliability because it 3D prints very properly out of the field. Customers who wish to obtain the highest quality and accuracy needs to be ready to spend some effort and time on tuning and optimizing the machine, however that is undoubtedly doable on the Ender-5 S1.

Specs

| Printing Know-how | FFF/FDM |

| Construct Quantity | 220*220*280mm |

| Product Dimensions | 425*460*570mm |

| Bundle Dimensions | 578*474*340mm |

| Internet Weight | 12.2kg |

| Gross Weight | 14.7kg |

| Extruder Kind | “Sprite” dual-gear |

| Extruder Materials | Direct Drive Extruder |

| Leveling Mode | CR Contact |

| Mainboard | 32-bit silent board |

| Max. Printing Velocity | ≤250mm/s |

| Typical Printing Velocity | <120mm/s |

| Acceleration | 2000mm/s2 |

| Nozzle Kind | Brass nozzle XL |

| Nozzle Diameter | Customary 0.4mm |

| Printing Accuracy | ±01mm |

| Layer Peak | 0.05-0.35mm |

| Filament Diameter | 1.75mm |

| Nozzle Temperature | <300°C |

| Heated Temperature | <110°C |

| Construct Floor | PC spring metal sheet |

| Energy Loss Restoration | Filament Runout Sensor |

| Rated Voltage | 100-120V~.200-240V~50/60Hz |

| Rated Energy | 350W |

| File Switch | SD card. USB Kind-C cable |

| File Codecs | STL, OBJ |

| Supported Filaments | PLA. PETG. ABS. TPU, PC. ASA. HIPS |

| Slicing Software program | Creality Slicer. Creality Print, Cura. Repetier-Host. Simplify3D |

| Ul Languages | English, Spanish, German, French, Russian, Portuguese, Italian, Turkish, and Chinese language |

Subscribe to the 3D Printing Trade e-newsletter to make sure you sustain with the newest 3D printing information. You can too comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Are you interested by working within the additive manufacturing business? Go to 3D Printing Jobs to view a choice of obtainable roles and kickstart your profession.

Featured picture reveals the Creality Ender-5 S1. Photograph by 3D Printing Trade.