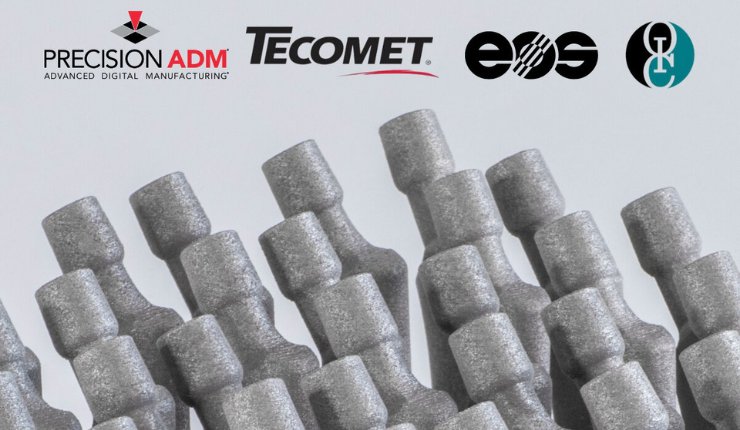

4 main firms within the medical system manufacturing business, EOS, Tecomet, Orthopaedic Innovation Centre (OIC) and Precision ADM introduced a collaborative partnership providing an end-to-end resolution for medical system 3D printing. The partnership features a vary of companies together with front-end engineering and design companies, 510k approval pathways, system and machine validation, pre-clinical testing, and commercialisation.

In accordance with EOS, the adoption of 3D printing within the medical system market is ‘quickly’ rising as a result of confirmed affected person advantages, and ‘uncertainty’ in world provide chains the place industrial 3D printing has confirmed to be extra strong.

EOS says that with the brand new partnership, an entire end-to-end resolution is supplied to clients ranging from product design and course of improvement over large-scale manufacturing, all the best way to testing, validation and FDA submission. In accordance with the corporate, the benefit for medical OEMs is a big discount in product improvement lead-time, and a lowered time to market and general threat.

Within the announcement concerning the partnership, EOS detailed the advantages that every firm is bringing to the desk. EOS stated that itself is a worldwide know-how chief in each metallic and polymer 3D printing; Tecomet is a specialist within the precision manufacturing of medical units and elements; OIC gives accredited medical system testing and contract scientific analysis companies to the orthopedic business; and Precision ADM gives complete engineering and AM contract companies to the medical system business.

EOS says the ‘complete’ workforce permits medical system producers to compress their time-to-market.

Spokespersons for every of the respective firms concerned within the new partnership commented on the information within the press launch concerning the announcement:

Dr. Gregory Hayes, EOS SVP of Utilized Engineering stated: “Scaling AM medical system manufacturing requires an entire understanding of the method chain which works past simply printing and contains design, post-processing, testing, sterilisation, and packaging amongst different steps. Our partnership with Tecomet, OIC and Precision ADM will yield unparalleled additive manufacturing experience to assist medical system producers navigate the complexities of the regulatory setting whereas delivering high-quality, dependable merchandise.”

Tecomet CEO Andreas Weller added: “The partnership with EOS, Precision ADM, and Orthopaedic Innovation Centre aligns with our steadfast strategy to supply full spectrum, scalable manufacturing options to the medical system market. Combining the most recent additive manufacturing applied sciences with our precision manufacturing experience is an extra dedication to this rising know-how. Our world clients are persistently in search of methods to get their merchandise to market sooner, this partnership paired with our distinctive high quality programs will supply a novel and complete resolution to the business.”

Trevor Gascoyne, CEO of OIC added: “We’re thrilled to work with superior manufacturing powerhouses EOS, Tecomet, and Precision ADM to supply end-to-end medical system manufacturing to main OEMs. Our famend testing capabilities and scientific analysis companies will streamline scientific implementation and commercialisation efforts not like another partnership within the business.”

Martin Petrak, CEO of Precision ADM concluded: “By partnering with EOS and Tecomet, we will supply an entire suite of engineering, AM, and machining options that can assist our clients carry their merchandise to market sooner. From supplies choices to lattice buildings, our engineering, testing, and manufacturing companies, mixed with the experience of EOS and Tecomet, will be certain that our clients have entry to the very best resolution for his or her wants.”

EOS not too long ago introduced that it was working with engineering software program developer nTop for the improvement of a brand new Implicit Interop functionality, which the businesses say solves a significant bottleneck within the additive manufacturing workflow, by permitting the switch of complicated designs in megabyte-sized information, quickening the time to manufacturing.