Constructing wind farms has lengthy been hindered by the logistical problem of transporting large wind turbine blades. Nevertheless, a brand new startup, Orbital Composites, is poised to rework the business with its use of 3D printing and robotics. The corporate’s CEO, Amolak Badesha, envisions a future the place wind generators are manufactured proper at their set up websites, circumventing the arduous transportation course of that has plagued the sector.

Orbital Composites has harnessed expertise that permits fast 3D printing of composite supplies. Not like the labor-intensive strategies presently employed in wind blade manufacturing, this method considerably reduces prices and waste. Conventional processes, as soon as dominated by offshore factories as a consequence of their handbook nature, have grow to be outdated, whereas Orbital’s on-site manufacturing technique guarantees to reinvigorate home manufacturing.

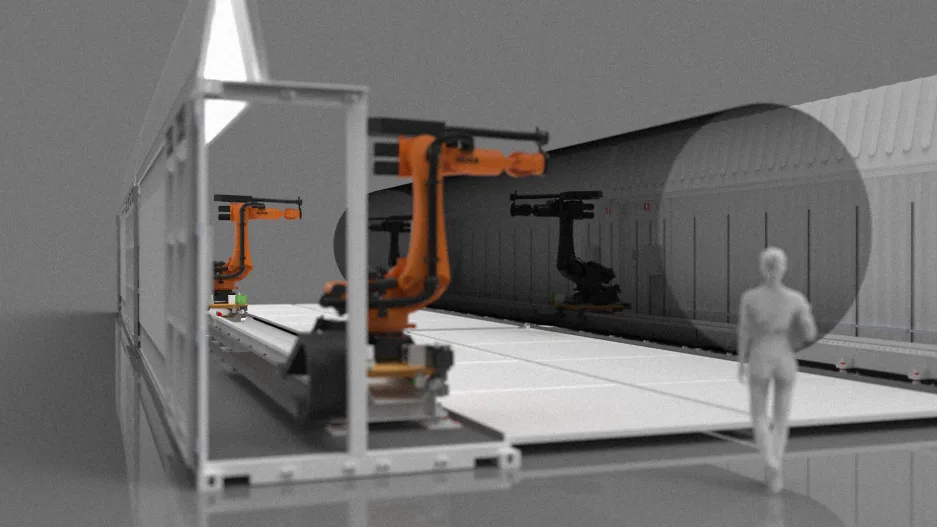

The startup’s method includes crafting colossal molds by 3D printing and subsequently producing the wind turbine blades inside these molds. All the manufacturing setup may be transported in delivery containers, eliminating the necessity to transfer the completed product and permitting for the creation of bigger blades. This innovation not solely enhances vitality output but additionally slashes manufacturing bills, with anticipated value reductions of as much as 25%.

3D Printing Complete Generators

Orbital Composites can also be on a path to 3D print bases, towers, and different elements for wind generators. The corporate’s future collaboration with the Division of Power to develop a cable-based 3D printing robotic represents an enormous stride ahead in on-site fabrication. This agile system will allow the creation of huge blades with out the necessity for in depth infrastructure, enabling wind vitality on bigger scales.

Orbital’s additionally plans to make use of recyclable supplies, to additional show its dedication to sustainability. With plans to create wind turbine blades that aren’t solely recyclable but additionally reusable downstream, the startup is charting a greener course for the business. The corporate will unveil its first 3D printed wind blade demonstration later this yr

Come and tell us your ideas on our Fb, Twitter, and LinkedIn pages, and don’t overlook to join our weekly additive manufacturing publication to get all the newest tales delivered proper to your inbox.