A brand new challenge known as Human Bio-inks for 3D printing (HU3DINKS) is aiming to develop human tissue-based bio-inks for 3D bioprinting. Funded by the IraSME initiative, this challenge goals to advertise cross-border collaborations.

The HU3DINKS consortium consists of companions from Belgium and Austria. THT Biomaterials (Vienna, Austria) contributes experience in human placenta-derived supplies, whereas BIO INX (Ghent, Belgium) focuses on bio-ink growth for numerous printing applied sciences. MorphoMed (Vienna, Austria) presents assist with medical grade silk know-how, and UpNano (Vienna, Austria) is famend for experience in 2PP (bio) high-resolution bio 3D printing applied sciences. Moreover, the organic validation of the newly developed bio-inks is carried out by the Ludwig Boltzmann Institute for Traumatology, along with AUVA.

“The know-how has made some great advances in efficiency however is now primarily restricted by the absence of high-performing organic supplies. The HU3DINKS challenge can induce a paradigm shift within the area by really mimicking the human mobile surroundings each when it comes to structure and composition,” mentioned, Markus Lunzer, Supplies Specialist at UpNano.

Towards extra human-like 3D bioprinting

At the moment, 3D bioprinting predominantly depends on supplies derived from animal sources, like gelatin or collagen. The necessity for animal-free alternate options arises to switch animal testing and higher resemble human tissue situations. Artificial polymers have been explored however lack the complexity of in vivo conditions, failing to bridge the hole between in vitro exams and animal fashions, says the consortium.

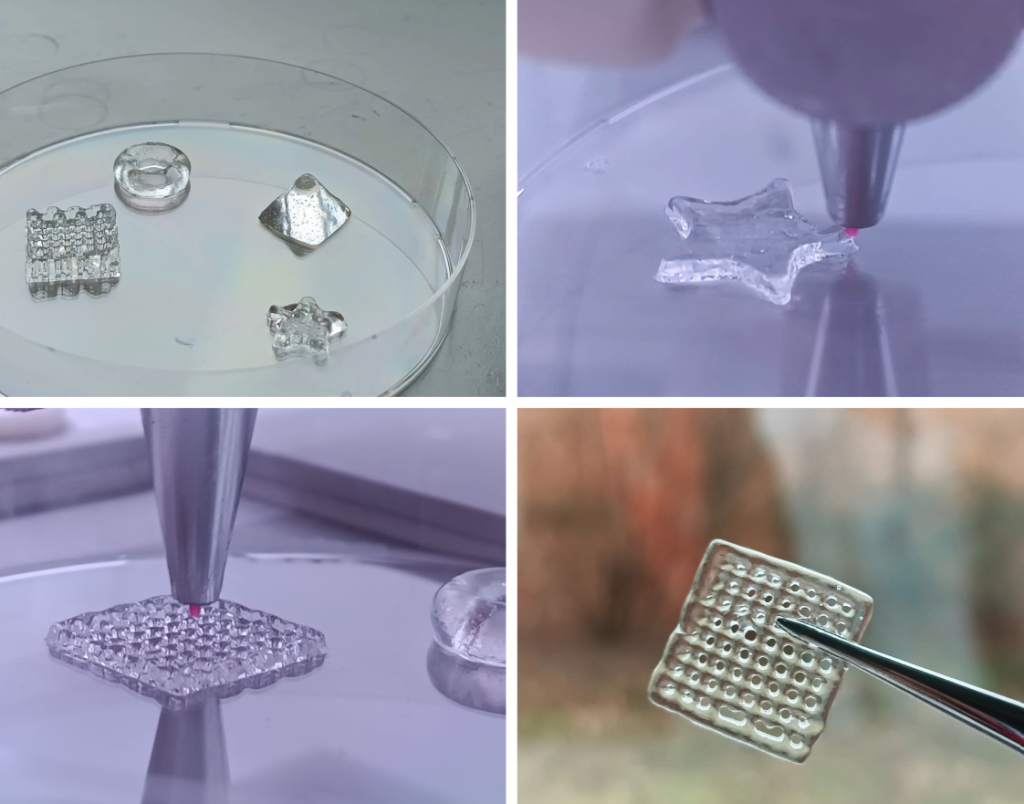

The HU3DINKS challenge goals to develop high-performing human tissue-based bio-inks for 3D bioprinting, together with extrusion and high-resolution laser-based strategies. Regardless of industrial human tissue-derived supplies being obtainable, their bioactivity and 3D printing efficiency stay poor. Thus, the HU3DINKS consortium seeks to transform these supplies into bio-inks for extra environment friendly 3D printing.

Consequently, 3D printed human tissue fashions supply a extra correct illustration of native 3D tissues in comparison with conventional 2D cell tradition strategies. This enables for testing medicine or cosmetics on these fashions, aligning with the 3R precept of decreasing, changing, and refining animal utilization in scientific analysis.

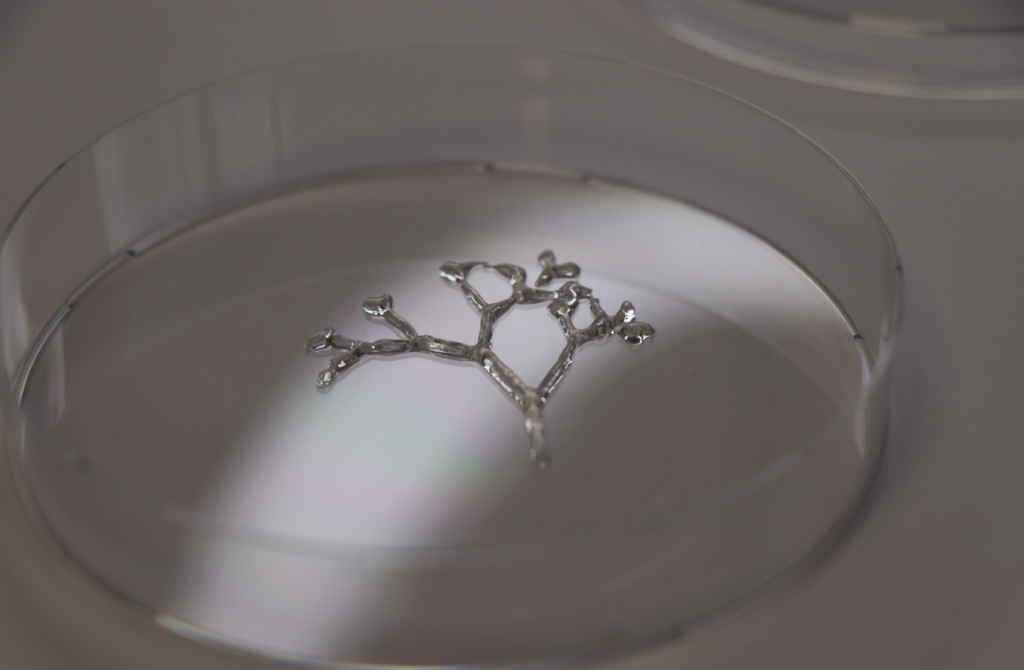

The purpose is completed by way of high-resolution bioprinting, significantly with the usage of 2-photon polymerization (2PP). This know-how permits for subcellular decision, successfully mimicking advanced microcellular structure. Furthermore, 2PP is without doubt one of the few strategies that facilitate direct printing inside microfluidic chips, streamlining the drug screening course of.

Bioprinting: A brand new technique to restore and substitute broken tissue

Final yr, 3D bioprinting specialist CollPlant launched a bio-ink referred to as ‘Collink.3D 90’ to its materials portfolio prior to now. This second recombinant human collagen (rhCollagen)-based materials was distinguished by its improved mechanical properties, particularly tailor-made to fulfill the 3D printing calls for of onerous and comfortable tissues. Moreover, the ink was reported to speed up cell migration, surpassing present cell-culturing hydrogels on this facet. This attribute made it a “promising selection” for the event of regenerative medicines, says CollPlant.

Finnish bioprinting firm Brinter, allied with Tampere College‘s Kellomäki Lab Biomaterials and Tissue Engineering Group to discover bio-inks for 3D printing and drive “developments within the bioprinting area.” Their first breakthrough concerned the event of a novel technique to create a photocrosslinkable bio-ink from gellan gum, a precursor recognized for its favorable rheological properties in hydrogels. Using a two-step crosslinking approach, the group efficiently reworked beforehand unprintable gellan gum inks into viable bio-inks, enabling the fabrication of 3D printed constructions. Moreover, the group proposed the potential of making use of this system to numerous different bioink formulations.

What does the way forward for 3D printing for the following ten years maintain?

What engineering challenges will should be tackled within the additive manufacturing sector within the coming decade?

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Business publication or comply with us on Twitter, or like our web page on Fb.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Are you in search of a job within the additive manufacturing trade? Go to 3D Printing Jobs for a collection of roles within the trade.

Featured picture exhibits HU3DINKS brand. Picture through Flam3D.